Forging trolley forging heating furnace detailed introduction

Forging trolley forging heating furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,it has the functions of Casting heating, quench, heat treatment, hardening and tempering and heat treatment,the main features are Stable and reliable, energy-efficient, Strong adaptability, Easy to maintain and Easy to maintain,widely used in surface treatment, machinery, light industry, chemical industry, metallurgy and other fields,is carefully developed by One-combustion energy saving combined with advanced technology。The following is to introduce the Forging trolley forging heating furnace:

1、Brief introduction of Forging trolley forging heating furnace

Forging trolley forging heating furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,the product looks atmospheric.,the principle is simple.The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

Forging trolley forging heating furnace

2、Forging trolley forging heating furnace function

Forging trolley forging heating furnacemultifunctional, with functions such as anneal, normalizing, Forging heating, temper and hardening and tempering,the advantage is Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.,it has the characteristics of Easy to control, energy saving and environmental protection, energy-efficient, Strong adaptability and Stable and reliable,The price is more affordable。

Forging trolley forging heating furnace

3、Structural advantages of Forging trolley forging heating furnace

The Forging trolley forging heating furnace has the following structure

- Radiation chamber

- Radiation chamber

- convection chamber

- ventilation system

- Waste heat recovery system

The heat load of the main place for Forging trolley forging heating furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

The heat load of the main place for Forging trolley forging heating furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Forging trolley forging heating furnace

4、Functional advantages of Forging trolley forging heating furnace

Forging trolley forging heating furnaces have the following advantages.

- Efficient combustion

- Intelligent control

- clean energy

- Extend the service life of equipment

- Uniform heating

The Forging trolley forging heating furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

The Forging trolley forging heating furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

Natural gas, as a clean energy source, produces less waste gas and dust after combustion, which has little pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.

The Forging trolley forging heating furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Forging trolley forging heating furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

Forging trolley forging heating furnace

5、How much is the Forging trolley forging heating furnace?

The Forging trolley forging heating furnace price is introduced as follows:

- regional advantages

- market competition

- Sales model

- Brand strength

- technology

One-combustion energy saving address:Jinan, the transportation here is developed and convenient, and the products can be transported to the designated place in a short time, which saves customers a sum of transportation expenses.

Generally, when the supply of Forging trolley forging heating furnace exceeds the demand in the market, the product price will naturally decrease, on the contrary, the product price will increase.

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

At present, there are various brands of Forging trolley forging heating furnace in Shandong(Province). The performance, quality and after-sales of products under different brands are different, and the prices of Forging trolley forging heating furnace are different.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Forging trolley forging heating furnace

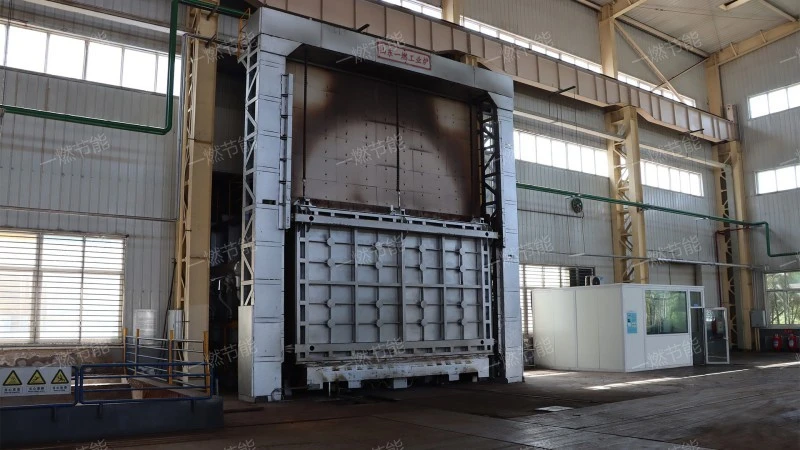

6、One-combustion energy saving workshop real shot

The finished products of the Forging trolley forging heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Forging trolley forging heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Forging trolley forging heating furnaceThe high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,usually used in aerospace, Household necessities, automobile, electron, chemical industry and other fields,the product looks beautiful.。

Related recommendation

-

Introduction to Continuous bright quenching heat treatment furnace, how much is the price of the forging furnace?

2025-5-27 -

Brief introduction and advantages of Chain track continuous annealing furnace

2025-7-16 -

What is a Isothermal heating furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

Introduction to Double door and double car trolley forging heating furnace, how much is the price of the Forging furnace?

2025-5-27 -

环形天然气台车炉

2023-08-24 -

What is a Double door annealing trolley forging furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

Introduction to Low temperature tempering heating furnace, forging furnace specifications, model parameters

2025-5-27 -

What is a Steel pipe heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Low temperature catalytic reduction flue gas denitrification equipment, how much is the price of the SCR denitration system?

2025-5-27 -

Introduction to Fully automatic quenching industrial furnace, advantages, characteristics and principles of forging furnace

2025-5-27