Brief introduction and advantages of Chain track continuous annealing furnace

Chain track continuous annealing furnaceIt is a forging heating device using gas as fuel.,it has the characteristics of energy-efficient, Strong adaptability, energy saving and environmental protection, energy saving and environmental protection and Strong adaptability,is a kind of high quality and low price Chain track continuous annealing furnace,It has the functions of Metal tempering, Metal heat treatment, Energy conservation and environmental protection, Improve production efficiency and Metal forging heating,be loved by our customers.。The following is to introduce the Chain track continuous annealing furnace:

1、Brief introduction of Chain track continuous annealing furnace

Chain track continuous annealing furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,Structure consists of combustor, Radiation chamber, recovery of waste heat, furnace chamber, ventilation system and so on,Chain track continuous annealing furnaceThe structural design is more advanced and reasonable.,it is widely used in light industry, machinery, aerospace, Household necessities, building materials and other industries。

Chain track continuous annealing furnace

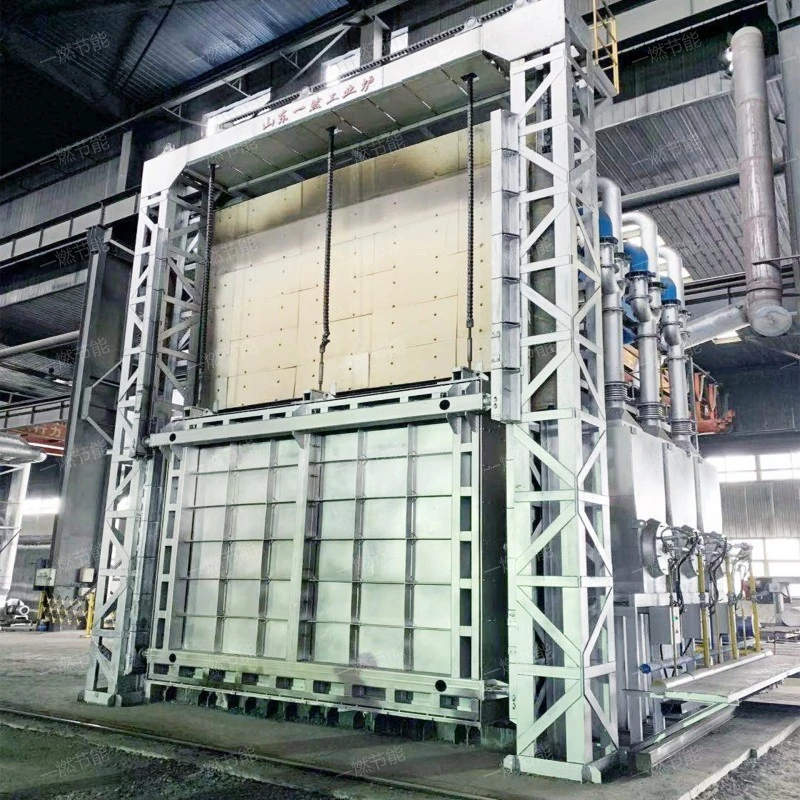

2、Chain track continuous annealing furnace customer scene picture

There are many specifications and models of Chain track continuous annealing furnace, which can be selected by users at will. The high-definition factory map is available for our customers to visit.。

Chain track continuous annealing furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Chain track continuous annealing furnace use

The purpose of Chain track continuous annealing furnace is introduced as follows:

- Metal forging heating

- Metal heat treatment

- Metal tempering

- Metal forging heating

- Energy conservation and environmental protection

The Chain track continuous annealing furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

In addition to forging heating, Chain track continuous annealing furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the Chain track continuous annealing furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Chain track continuous annealing furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

The Chain track continuous annealing furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

Chain track continuous annealing furnace

4、Chain track continuous annealing furnace function

Chain track continuous annealing furnacemultifunctional, with functions such as heat treatment, anneal, quench, Forging heating and temper,it has been widely used in war industry, surface treatment, Household necessities, shipping, pharmacy and other industries,it has the characteristics of Stable and reliable, energy-efficient, Easy to control, Easy to maintain and Easy to maintain。

Chain track continuous annealing furnace

5、Chain track continuous annealing furnace price

The Chain track continuous annealing furnace price is introduced as follows:

- Less intermediate links

- Configuration level

- Low cost of raw materials

- company strength

- technology content

If there is no middleman to earn the difference, then the Chain track continuous annealing furnace price will naturally decrease. One-combustion energy saving adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

Products of the same style, different configurations, the product price is definitely different, therefore, the Chain track continuous annealing furnace price is affected by the configuration, and the price varies.

Production costs include raw material costs, labor costs, other costs, etc., which manufacturers need to invest when producing products, but these factors are not certain. They are affected by the market. When one factor in the market changes, the production costs of manufacturers will also change, and the price of Chain track continuous annealing furnace will also fluctuate to some extent.

There are many manufacturers of products in Jinan, Shandong province, and the strength, technology and after-sales of each manufacturer are different, so the quotation for Chain track continuous annealing furnace is naturally different.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Chain track continuous annealing furnace

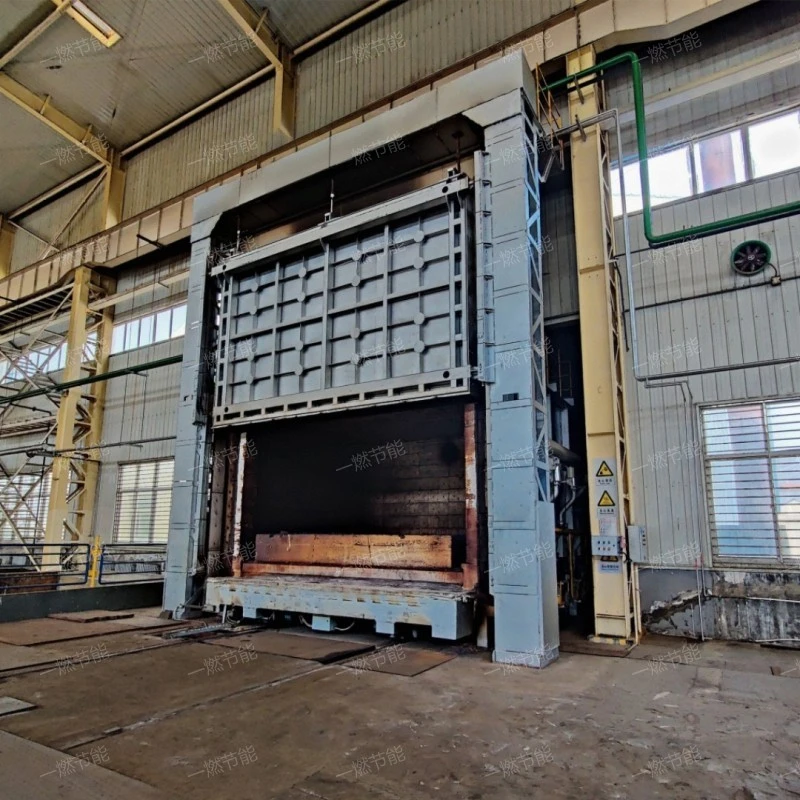

6、Real-time shooting in One-combustion energy saving's production workshop

The finished products of the Chain track continuous annealing furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Chain track continuous annealing furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Chain track continuous annealing furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,is a Chain track continuous annealing furnace,It is a product series that integrates Metal melting and casting, Metal tempering, Metal heat treatment, Metal forging heating and Metal melting and casting。

Related recommendation

-

What is a Multi tube heating furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Quenching heat treatment heating furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Decarbonization annealing heat treatment furnace and heating furnace structure principle

2025-5-27 -

What is a Industrial heating furnace denitrification? Introduction to the advantages and characteristics of SCR denitration system functions

2025-5-27 -

What is a Electric tempering furnace? Introduction to the advantages and characteristics of the Trolley resistance heating furnace

2025-5-27 -

What is a Isothermal continuous quenching heat treatment furnace? How much is the price of the forging furnace?

2025-5-27 -

What is a Foundry flue gas denitrification? SCR flue gas denitrification specifications, models, and parameters

2025-5-27 -

What is a Bearing steel heating furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

Introduction to Pressure vessel heating furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

Pressure vessel trolley forging heating furnace detailed introduction

2025-6-18