Introduction to Side entry and side exit step heat treatment furnace, how much is the price of the heating furnace?

Side entry and side exit step heat treatment furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,it is mainly composed of furnace chamber, recovery of waste heat, Radiation chamber, ventilation system and Radiation chamber,This productThe structural design is more advanced and reasonable.。The following is to introduce the Side entry and side exit step heat treatment furnace:

1、Brief introduction of Side entry and side exit step heat treatment furnace

Side entry and side exit step heat treatment furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,features include Stable and reliable, Strong adaptability, Easy to control, Strong adaptability and energy-efficient,is a kind of high quality and low price Side entry and side exit step heat treatment furnace,was developed and designed by One-combustion energy saving。

Side entry and side exit step heat treatment furnace

2、Introduction of Side entry and side exit step heat treatment furnace characteristics

Side entry and side exit step heat treatment furnace has the following characteristics

- Strong adaptability

- Stable and reliable

- energy saving and environmental protection

- energy saving and environmental protection

- Stable and reliable

The Side entry and side exit step heat treatment furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The Side entry and side exit step heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Side entry and side exit step heat treatment furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Side entry and side exit step heat treatment furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

The Side entry and side exit step heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

Side entry and side exit step heat treatment furnace

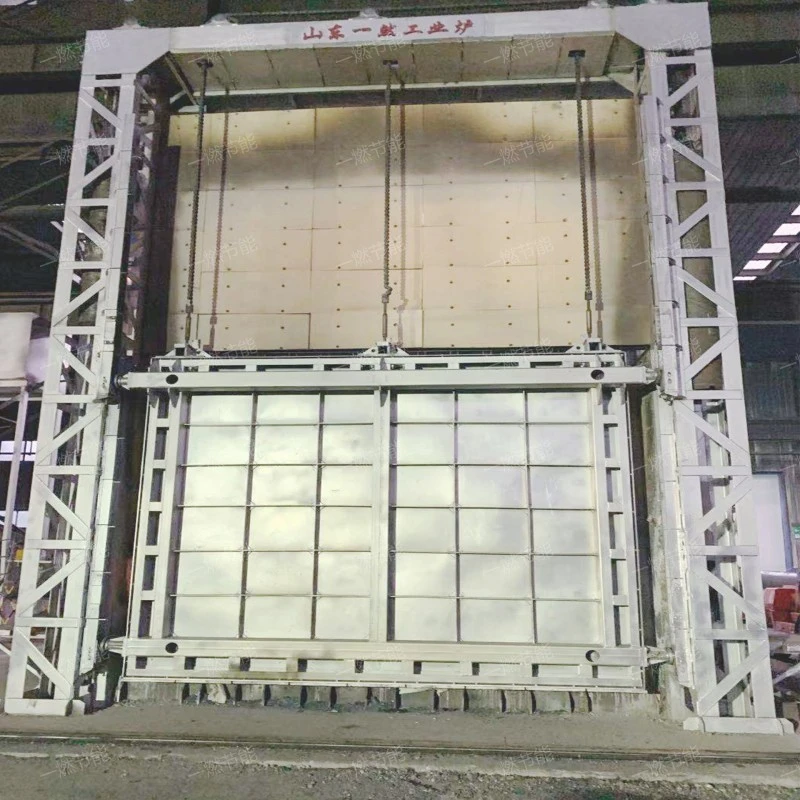

3、Side entry and side exit step heat treatment furnace real beat

The details of the Side entry and side exit step heat treatment furnace are displayed in many directions, and the Side entry and side exit step heat treatment furnace is beautiful and cost-effective.。

Side entry and side exit step heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Working principle of Side entry and side exit step heat treatment furnace

Side entry and side exit step heat treatment furnacethe principle is simple.The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,It is an efficient, energy-saving and environment-friendly metal heating device.,is a Side entry and side exit step heat treatment furnace,it can be used in automobile, heat treatment, surface treatment, Household necessities, chemical industry and other industries,Widely used inMetal heat treatment,Metal forging heating,Metal melting and casting,Energy conservation and environmental protection,Improve production efficiency and so on。

Side entry and side exit step heat treatment furnace

5、Side entry and side exit step heat treatment furnace price consultation

The Side entry and side exit step heat treatment furnace price is introduced as follows:

- market

- Reasonable cost

- Cost input

- Manufacturer's sales model

- Configuration level

With the increasingly fierce competition of Side entry and side exit step heat treatment furnace, market factors have a certain influence on the price of Side entry and side exit step heat treatment furnace. When the demand in the market increases and the supply remains unchanged, the price will rise. On the contrary, the price will fall. When there is an increase in supply and the demand remains unchanged, the price will rise, on the contrary, the price will fall.

The cost of manufacturing Side entry and side exit step heat treatment furnace varies from manufacturer to manufacturer. The higher the cost of manufacturing products, the higher the product price will be. On the other hand, the lower the production cost, the lower the product price, but the quality of products with high production cost is guaranteed, which can reduce the maintenance cost of customers.

When the Side entry and side exit step heat treatment furnace is manufactured, the materials selected by different manufacturers will be different. Some manufacturers use high-quality materials, and the price will be relatively high, while some manufacturers use ordinary materials, and the price will be lower.

If there is no middleman to earn the difference, then the Side entry and side exit step heat treatment furnace price will naturally decrease. One-combustion energy saving adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Side entry and side exit step heat treatment furnace are closely related. One-combustion energy saving has comprehensively measured the configuration and sales price of products when designing Side entry and side exit step heat treatment furnace, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

Side entry and side exit step heat treatment furnace

6、One-combustion energy saving after-sales service

One-combustion energy saving has perfect and reasonable after-sales service, which can solve customers' problems in a short time and reduce customers' losses. One-combustion energy saving can provide strong protection for customers in the later stage.。

One-combustion energy saving

Side entry and side exit step heat treatment furnacethe advantage is Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.,is a common Side entry and side exit step heat treatment furnace,is a kind of high quality and low price Side entry and side exit step heat treatment furnace。

Related recommendation

-

What is a Natural gas truck furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Circulating trolley forging heating furnace and Forging furnace advantages and features

2025-5-27 -

Introduction to Regenerative through forging heating furnace and forging furnace working principle

2025-5-27 -

What is a Double door trolley forging heating furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

Introduction to Double bridge trolley resistance heating furnace, introduction to Trolley resistance heating furnace advantages and characteristics

2025-5-27 -

Introduction to Gas storage chamber heating furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Forging box type heating furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Medium temperature heat treatment resistance furnace and Trolley resistance heating furnace working principle

2025-5-27 -

Introduction to Gas tube furnace and forging furnace advantages and features

2025-5-27 -

What is a Stick type continuous heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27