Introduction to Thin plate heating furnace, Forging furnace advantages, characteristics and principles

Thin plate heating furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.,multifunctional, with functions such as Forging heating, normalizing, temper, heat treatment and Casting heating,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,be loved by our customers.。The following is to introduce the Thin plate heating furnace:

1、Brief introduction of Thin plate heating furnace

Thin plate heating furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,it is widely used inshipping,surface treatment,machinery,heat treatment,building materials and other industries,structure mainly includes: combustor, convection chamber, recovery of waste heat, combustor, ventilation system and so on,is a Thin plate heating furnace newly developed by One-combustion energy saving。

Thin plate heating furnace

2、Advantages of Thin plate heating furnace principle

Thin plate heating furnaceHeat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,Mainly used forImprove production efficiency,Metal tempering,Energy conservation and environmental protection,Metal melting and casting andMetal heat treatment,it has the characteristics of Stable and reliable, energy saving and environmental protection, Easy to maintain, Stable and reliable and energy saving and environmental protection,be loved by our customers.。

Thin plate heating furnace

3、Thin plate heating furnace function

Thin plate heating furnaceit has the functions of anneal, hardening and tempering, temper, quench and Forging heating,It is an efficient, energy-saving and environment-friendly metal heating device.,usually used in aerospace, metallurgy, Machinery manufacturing, material, war industry and other fields,the main features are Easy to control, Strong adaptability, energy-efficient, energy saving and environmental protection and energy-efficient,it is an ideal choice for customers to buy Thin plate heating furnace。

Thin plate heating furnace

4、Thin plate heating furnace performance advantage

Thin plate heating furnaces have the following advantages.

- Improve product quality

- easy to operate

- Efficient combustion

- Extend the service life of equipment

- Intelligent control

Because the Thin plate heating furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

The operation interface of the Thin plate heating furnace is friendly and easy for operators to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.

The Thin plate heating furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

The Thin plate heating furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Thin plate heating furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

Thin plate heating furnace

5、Thin plate heating furnace price concessions

The Thin plate heating furnace price is introduced as follows:

- service

- select a qualified person

- Parameter size

- technology

- Cost input

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Thin plate heating furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Thin plate heating furnace price can meet the purchasing needs of customers.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

Different customers need different output, different specifications, different product configurations, and their Thin plate heating furnace prices are also different. The bigger the specification, the stronger the performance of the product and the higher the quotation.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

Product manufacturers are different, and the cost spent by each manufacturer in producing products is definitely different. The higher the cost of producing products, the higher the price of products set by manufacturers. On the contrary, the Thin plate heating furnace price is low.

Thin plate heating furnace

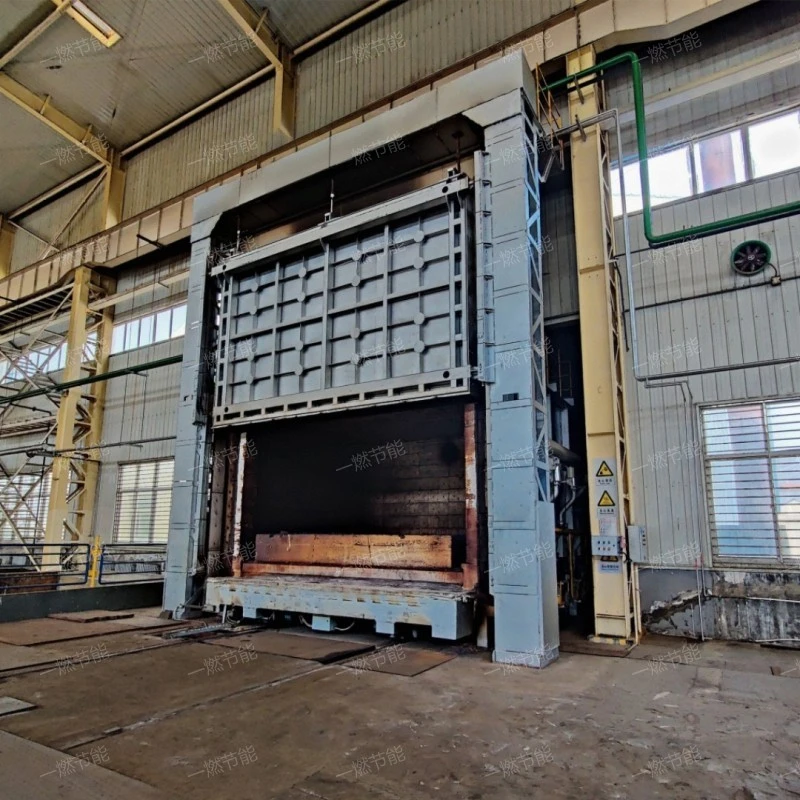

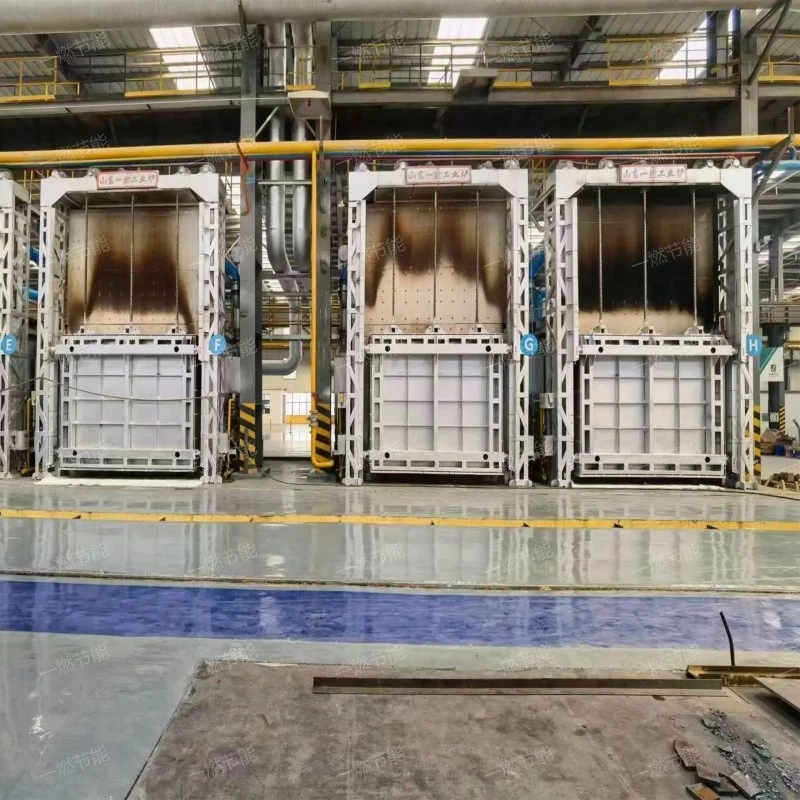

6、One-combustion energy saving workshop real shot

The finished products of the Thin plate heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Thin plate heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Thin plate heating furnacethe product looks beautiful.,It has a wide range of uses, including Metal tempering, Metal forging heating, Metal heat treatment, Energy conservation and environmental protection and Metal forging heating,in the course of work,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.。

Related recommendation

-

Introduction to Forging forging heating furnace and heating furnace working principle

2025-5-27 -

Introduction to Forging box furnace and forging furnace advantages and features

2025-5-27 -

What is a Regenerative burner trolley forging heating furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

What is a Trolley calcination furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to tube furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

Introduction to Roller type guide rail annealing furnace and Forging furnace advantages and features

2025-5-27 -

Introduction to Regenerative trolley furnace, how much is the price of the forging furnace?

2025-5-27 -

Introduction to Natural gas tube furnace and heating furnace structure principle

2025-5-27 -

What is a Mobile electric heating furnace? Introduction to the advantages, characteristics, and principles of the Trolley electric furnace

2025-5-27 -

What is a Environmentally friendly box type heating furnace? Introduction to the Working Principle of Forging furnace

2025-5-27