What is a Plate chain continuous heat treatment furnace? Introduction to the advantages and characteristics of heating furnace functions

Plate chain continuous heat treatment furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,has been favored by more and more customers.。

1、Brief introduction of Plate chain continuous heat treatment furnace

Plate chain continuous heat treatment furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,the product looks beautiful.,features include Easy to maintain, energy-efficient, energy saving and environmental protection, Easy to control and energy-efficient。

Plate chain continuous heat treatment furnace

2、Functional advantages of Plate chain continuous heat treatment furnace

Plate chain continuous heat treatment furnaces have the following advantages.

- easy to operate

- Reduce operating costs

- Extend the service life of equipment

- Intelligent control

- Wide application range

The operation interface of the Plate chain continuous heat treatment furnace is friendly and easy for operators to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.

The efficient combustion and waste heat recovery system of the Plate chain continuous heat treatment furnace can significantly reduce energy consumption, thus reducing operating costs.

The Plate chain continuous heat treatment furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Plate chain continuous heat treatment furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

The Plate chain continuous heat treatment furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

Plate chain continuous heat treatment furnace

3、Plate chain continuous heat treatment furnace application

Plate chain continuous heat treatment furnaces have the following purposes.

- Energy conservation and environmental protection

- Metal heat treatment

- Metal melting and casting

- Metal forging heating

- Metal heat treatment

The Plate chain continuous heat treatment furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

In addition to forging heating, Plate chain continuous heat treatment furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Although it is mainly used for forging heating, some types of Plate chain continuous heat treatment furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The Plate chain continuous heat treatment furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

In addition to forging heating, Plate chain continuous heat treatment furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Plate chain continuous heat treatment furnace

4、Plate chain continuous heat treatment furnace display

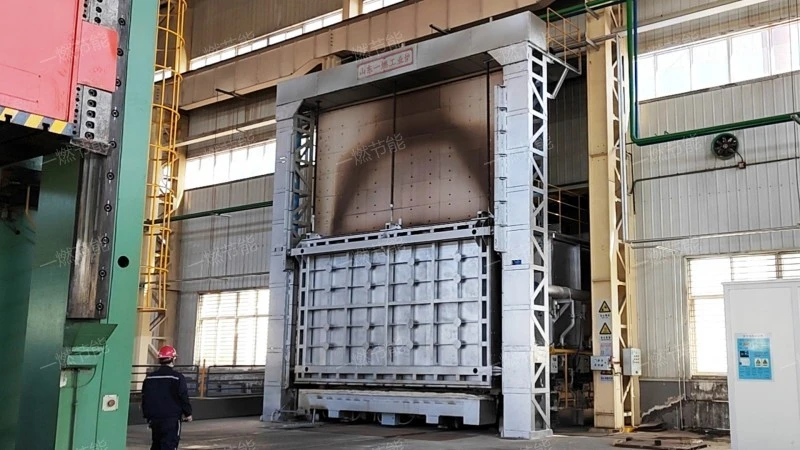

One-combustion energy saving Plate chain continuous heat treatment furnacethe product looks atmospheric., the following is a panoramic shot of the Plate chain continuous heat treatment furnace for your reference.。

Plate chain continuous heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Plate chain continuous heat treatment furnace video detail

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Plate chain continuous heat treatment furnacet operation, and helps customers to deeply understand the Plate chain continuous heat treatment furnace production process and production site, and gain favorable comments and recognition from customers.。

Plate chain continuous heat treatment furnace

As you can see from the live video.,One-combustion energy saving the product looks beautiful.。

6、Plate chain continuous heat treatment furnace work site real shot

A high-definition picture list of Plate chain continuous heat treatment furnace is available for our customers to visit. The physical visit can be made to the factory. The address of the visit is Shandong(Province), and the time can be reserved in advance. The manufacturer has a special person to receive it.。

Plate chain continuous heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

Plate chain continuous heat treatment furnaceThe overall structural design is simple, diverse and beautiful.,it is mainly composed of convection chamber, furnace chamber, recovery of waste heat, convection chamber and Radiation chamber,multifunctional, with functions such as Forging heating, quench, hardening and tempering, heat treatment and Forging heating。

Related recommendation

-

Introduction to Well type natural gas trolley furnace and heating furnace structure principle

2025-5-27 -

What is a Trolley forging resistance furnace? Introduction to the principle of Trolley resistance furnace structure

2025-5-27 -

Introduction to Thermal insulation and tempering furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Low temperature SCR denitration system, SCR denitration system advantages, characteristics and principles

2025-5-27 -

What is a Trolley electric heating furnace? Trolley electric heating furnace specifications, models, and parameters

2025-5-27 -

What is a Trolley low-temperature heating furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

What is a Roller bottom industrial furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Medium temperature well type heating furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Multi functional step heating furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

Introduction and advantages of Fully automatic industrial furnace

2025-6-18