Introduction to Stepping bottom industrial furnace and heating furnace working principle

Stepping bottom industrial furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.。The following is to introduce the Stepping bottom industrial furnace:

1、Brief introduction of Stepping bottom industrial furnace

Stepping bottom industrial furnaceIt is a forging heating device using gas as fuel.,at work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.。

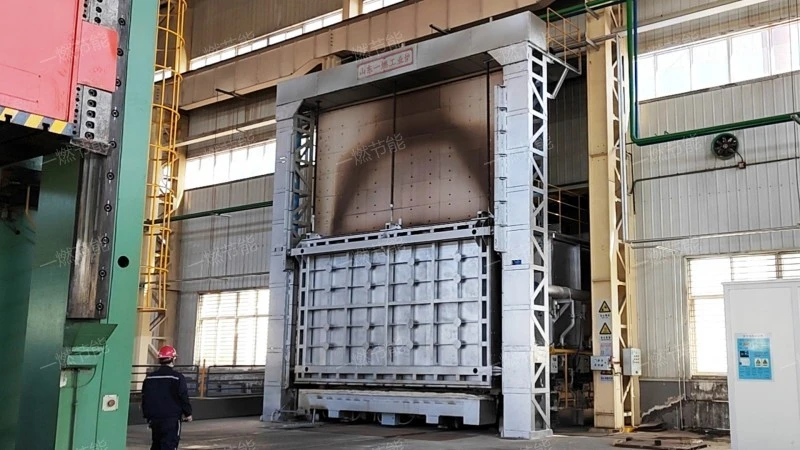

Stepping bottom industrial furnace

2、Stepping bottom industrial furnace display

Different specifications and models of high-definition pictures, so that everyone can see enough at once.。

Stepping bottom industrial furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

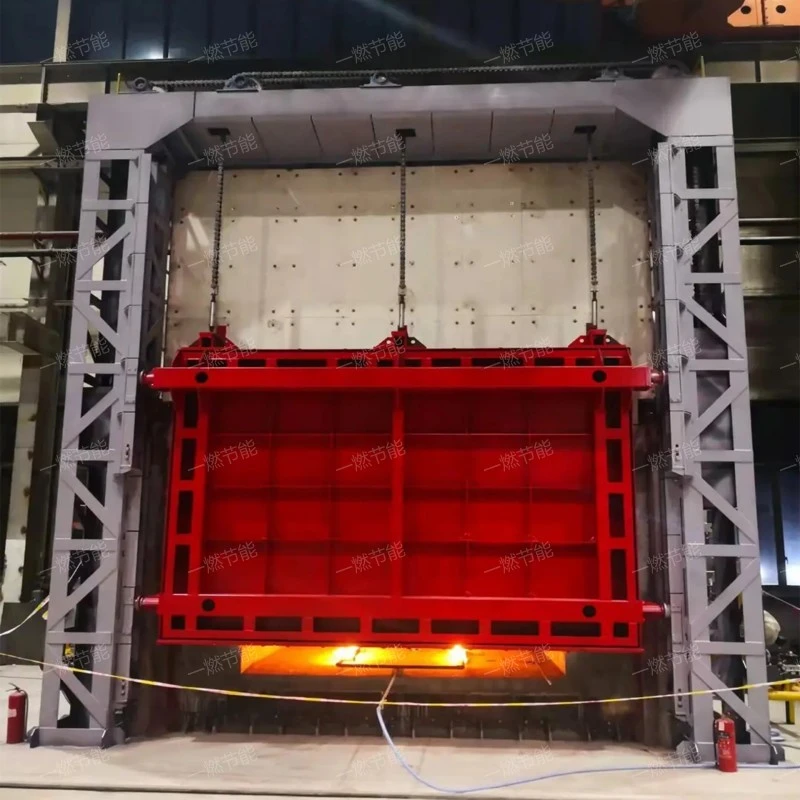

3、Stepping bottom industrial furnace principle

Stepping bottom industrial furnaceThe high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,the product looks atmospheric.,It is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,reliable quality。

Stepping bottom industrial furnace

4、Stepping bottom industrial furnace function

Stepping bottom industrial furnaceit has the functions of normalizing, hardening and tempering, anneal, quench and heat treatment,is a Stepping bottom industrial furnace newly developed by One-combustion energy saving。

Stepping bottom industrial furnace

5、Stepping bottom industrial furnace price

The Stepping bottom industrial furnace price is introduced as follows:

- regional advantages

- manufacturing cost

- raw material

- product function

- Self quality

One-combustion energy saving has a geographical advantage, where the transportation is developed, the product transportation cost is low, and the price and consumption level are also low, which provides a good sales environment for Stepping bottom industrial furnace.

Production costs include raw material costs, labor costs, other costs, etc., which manufacturers need to invest when producing products, but these factors are not certain. They are affected by the market. When one factor in the market changes, the production costs of manufacturers will also change, and the price of Stepping bottom industrial furnace will also fluctuate to some extent.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Generally speaking, the higher the product quality, the higher the Stepping bottom industrial furnace price. A reasonable balance is made between quality and price, so that the comprehensive quality of the product can meet the customer's use standards and meet the basic needs of customers in terms of price.

Stepping bottom industrial furnace

6、company introduction

One-combustion energy saving is a professional and large-scale Stepping bottom industrial furnace manufacturer, which has many years of production and operation, complete production facilities, skilled staff and high production capacity and product quality. It is a Stepping bottom industrial furnace manufacturer trusted by consumers at present.。

One-combustion energy saving

Stepping bottom industrial furnaceit is mainly composed of ventilation system, recovery of waste heat, combustor, furnace chamber and ventilation system,it has the characteristics of energy saving and environmental protection, Easy to maintain, Stable and reliable, Strong adaptability and energy-efficient,It is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.。

Related recommendation

-

What is a SCR catalyst flue gas denitrification equipment? Introduction to the advantages and characteristics of the SCR denitration system

2025-5-27 -

Introduction to Environmentally friendly chain heating furnace and Forging furnace working principle

2025-5-27 -

What is a Trolley high temperature test furnace? Forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Plate chain continuous annealing furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

What is a Regenerative burner tube heating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Gas through forging furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Rolling mill natural gas trolley furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Energy saving box furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Fully enclosed trolley furnace and Forging furnace working principle

2025-5-27 -

Introduction to Roller bottom mold heating furnace and forging furnace structure principle

2025-5-27