Introduction to Rotary quenching furnace and Forging furnace structure principle

Rotary quenching furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,the product looks atmospheric.,super quality and competitive price。

1、Brief introduction of Rotary quenching furnace

Rotary quenching furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,features include Stable and reliable, energy-efficient, Easy to maintain, energy-efficient and Easy to control,it has the functions of normalizing, heat treatment, temper, quench and anneal,the principle is simple.Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,The overall structural design is simple, diverse and beautiful.,Structure consists of ventilation system, furnace chamber, combustor, convection chamber, recovery of waste heat and so on。

Rotary quenching furnace

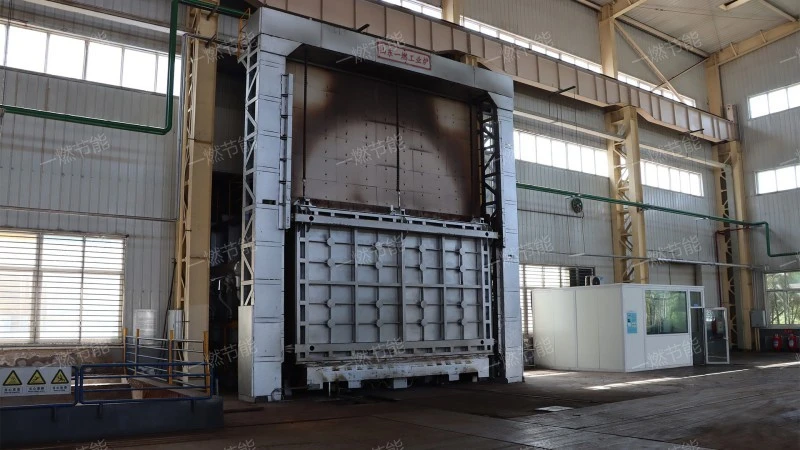

2、Rotary quenching furnace HD real shot

One-combustion energy saving Rotary quenching furnace complete specifications and models, new and old customers can choose at will, and high-definition pictures are available for customers' reference.。

Rotary quenching furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Rotary quenching furnace use

The purpose of Rotary quenching furnace is introduced as follows:

- Metal heat treatment

- Energy conservation and environmental protection

- Metal melting and casting

- Metal tempering

- Metal forging heating

In addition to forging heating, Rotary quenching furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

The Rotary quenching furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

Although it is mainly used for forging heating, some types of Rotary quenching furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

By properly heating and cooling the metal material, the Rotary quenching furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Rotary quenching furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Rotary quenching furnace

4、Rotary quenching furnace function

Rotary quenching furnaceit has the functions of normalizing, Casting heating, Forging heating, hardening and tempering and heat treatment,The price is low and affordable。

Rotary quenching furnace

5、Rotary quenching furnace price concessions

The Rotary quenching furnace price is introduced as follows:

- Reasonable cost

- select a qualified person

- Overall configuration

- regional difference

- Manufacturer scale

Cost plays a decisive role in the price. The cost mainly includes the initial investment of the product, such as time, manpower and materials selected. The more the investment cost, the higher the relative product pricing. On the contrary, the less the input cost, the lower the price.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

The difference in Rotary quenching furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

One-combustion energy savingShandong(Province), the transportation is convenient, and the corresponding cost of transporting Rotary quenching furnace is low, which reduces the cost of selling Rotary quenching furnace by manufacturers, and the price will also decrease.

There are many Rotary quenching furnace manufacturers on the market. Different manufacturers spend different costs, such as material costs, labor costs, manufacturing costs, etc., and their products are quoted differently.

Rotary quenching furnace

6、One-combustion energy saving service

Users should not only consider the quality, performance and price factors when buying Rotary quenching furnace, but also consider the after-sales service of manufacturers. Good after-sales service can reduce many unnecessary troubles for customers. One-combustion energy saving manufacturers always adhere to the service attitude of "customer is God", implement high-standard and high-quality after-sales service attitude, conduct regular customer satisfaction surveys, and strictly supervise the quality of after-sales service, so as to relieve customers' purchase worries and make buyers completely worry-free.。

One-combustion energy saving

Rotary quenching furnaceIt has a wide range of uses, and is often used inMetal forging heating,Improve production efficiency,Metal heat treatment,Metal tempering,Metal tempering and so on,It is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.。

Related recommendation

-

Introduction to Trolley split furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

Introduction to Large trolley heating furnace and Forging furnace working principle

2025-5-27 -

Introduction to Dual car resistance heating furnace and Trolley resistance heating furnace structure principle

2025-5-27 -

Introduction to Modular walking furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

What is a Nonferrous metal heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

What is a Well shaped spheroidization annealing furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

What is a Regenerative natural gas box type heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

What is a Continuous spheroidization annealing heating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Explosion proof trolley forging heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Steel chain spheroidization annealing furnace and heating furnace working principle

2025-5-27