Introduction to Pneumatic ash removal material sealing pump, introduction to Material seal pump advantages and characteristics

Pneumatic ash removal material sealing pumpIt is an advanced pneumatic conveying equipment for powder.,it has the functions of Waste disposal, Raw material transportation, System supporting use, Conveying of powdery materials and Dust control,Simple structure and advanced technology.,it is mainly composed of Nozzle adjusting device, Feed port and discharge port, sealing device, Cylindrical pump body and Bottom vaporization device。

1、Brief introduction of Pneumatic ash removal material sealing pump

Pneumatic ash removal material sealing pumpIt is an advanced pneumatic conveying equipment for powder.,it has been widely used in pottery and porcelain, glass, Alumina powder conveying, environmental protection, pottery and porcelain and other industries,at runtime,Using the action of air jet, the air drives the ash particles to send the ash to ash storage. There are two main sources of energy, one is the kinetic energy of the fan, and the other is the potential energy of the material column. When the material column is high, the potential energy is high and the pressure is high, the conveying capacity is correspondingly large, and vice versa.,is developed and improved by hyde。

Pneumatic ash removal material sealing pump

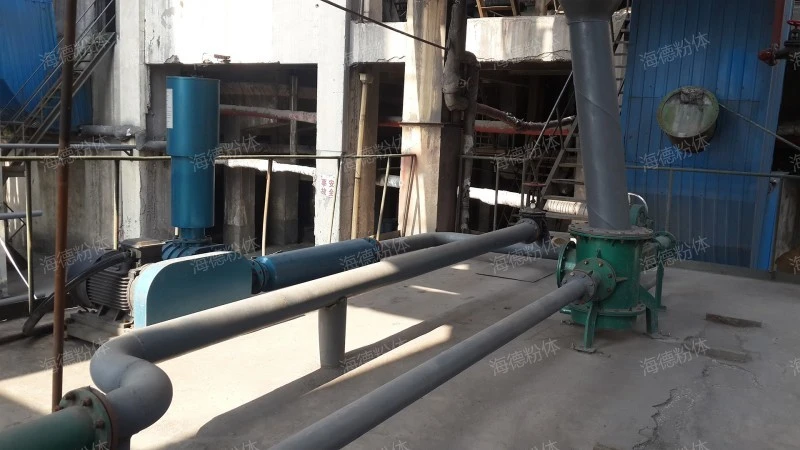

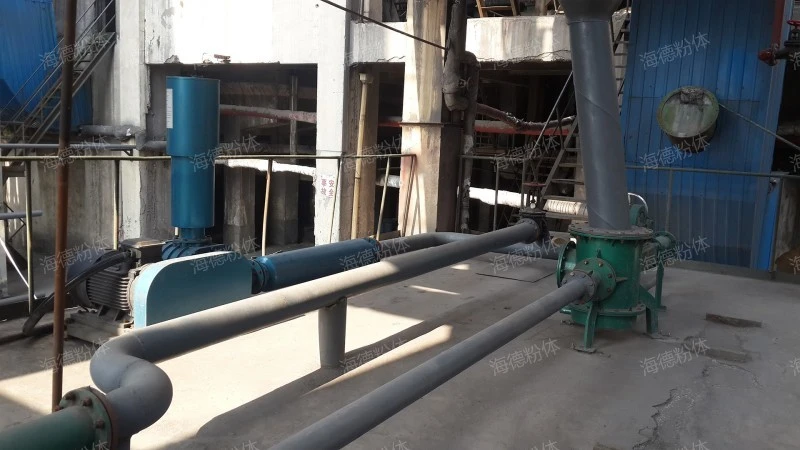

2、Pneumatic ash removal material sealing pump work site real shot

High-definition picture display of Pneumatic ash removal material sealing pump, excellent material selection, reliable quality and trustworthy.。

Pneumatic ash removal material sealing pump

Note: All the pictures in this article were taken by hyde manufacturer.。

3、Pneumatic ash removal material sealing pump function

Pneumatic ash removal material sealing pumpmultifunctional, with functions such as Waste disposal, Long-distance or complex terrain material transportation, Raw material transportation, System supporting use and Conveying of powdery materials,at the start of the operation,Using the action of air jet, the air drives the ash particles to send the ash to ash storage. The energy when the Pneumatic ash removal material sealing pump works comes from two parts: one part is the kinetic energy of the fan, and the other part is the potential energy of the material column. When the material column is high, the potential energy is high and the pressure is high, the conveying capacity is correspondingly large, and vice versa.,it is mainly composed of sealing device, Feed port and discharge port, injector, Nozzle adjusting device and Supporting and connecting parts。

Pneumatic ash removal material sealing pump

4、Structural characteristics of Pneumatic ash removal material sealing pump

The Pneumatic ash removal material sealing pump has the following structure

- Supporting and connecting parts

- Nozzle adjusting device

- Supporting and connecting parts

- sealing device

- Feed port and discharge port

The supporting and connecting parts are used to support and connect various parts of the Pneumatic ash removal material sealing pump to ensure the stability and integrity of the pump body. The design and manufacture of these components need to consider factors such as strength, stiffness and stability.

The nozzle adjusting device is used to adjust the air outlet volume and air outlet angle of the nozzle to adapt to different conveying requirements and powder characteristics. By adjusting the nozzle adjusting device, the conveying performance of the Pneumatic ash removal material sealing pump can be optimized and the conveying efficiency and stability can be improved.

The supporting and connecting parts are used to support and connect various parts of the Pneumatic ash removal material sealing pump to ensure the stability and integrity of the pump body. The design and manufacture of these components need to consider factors such as strength, stiffness and stability.

The sealing device is an important part in the Pneumatic ash removal material sealing pump, which is used to ensure the tightness inside the pump body and prevent the leakage of airflow and powder. The design and manufacture of sealing device need to consider the factors such as wear resistance, corrosion resistance and sealing performance.

The inlet is used to add powder materials into the Pneumatic ash removal material sealing pump, and the outlet is responsible for discharging the transported powder materials. The design of inlet and outlet needs to consider the fluidity, sealing and easy cleaning of powder.

Pneumatic ash removal material sealing pump

5、Pneumatic ash removal material sealing pump application

Pneumatic ash removal material sealing pumps have the following purposes.

- System supporting use

- Waste treatment and reuse

- Dust control in environmental protection field

- Powder material conveying

- System integration and customization

The Pneumatic ash removal material sealing pump can also be used as a supporting equipment for large-scale pneumatic conveying system or powder treatment system, and work together with other equipment to realize automatic and continuous powder conveying.

Pneumatic ash removal material sealing pumps can also be used in the field of waste treatment, such as conveying fly ash and other wastes for the production of environmentally friendly bricks or other recycling ways.

In the field of environmental protection, Pneumatic ash removal material sealing pumps play an important role. It can be used to collect and transport dust produced in industrial production process, thus effectively reducing dust pollution and improving working environment. In addition, the fully sealed design of the Pneumatic ash removal material sealing pump also prevents the leakage of dust and protects the surrounding environment.

The Pneumatic ash removal material sealing pump is mainly used for conveying all kinds of dry and loose powder materials, such as fly ash, alumina powder, dry kiln ash, limestone powder, cement powder and so on.

The Pneumatic ash removal material sealing pump can also be used as an integrated part of a large pneumatic conveying system or a powder processing system. According to customers' specific needs and scenarios, the Pneumatic ash removal material sealing pump can be customized and optimized to achieve a more efficient and reliable powder conveying solution.

Pneumatic ash removal material sealing pump

6、Pneumatic ash removal material sealing pump performance advantage

Pneumatic ash removal material sealing pumps have the following advantages.

- energy saving and environmental protection

- Continuous conveying

- regulate automatically

- Strong adaptability and flexible layout

- Completely sealed and pollution-free.

The fully sealed design also reduces dust emission and is beneficial to environmental protection.

It can be transported continuously, and the output of equipment can be automatically adjusted to achieve good ash conveying effect.

It can automatically adjust the output to achieve good ash conveying effect.

It can be flexibly arranged and configured according to the specific situation of the system.

By adopting low positive pressure and fully sealed transportation mode, foreign substances cannot enter the pipe, and the properties of the required materials will not be changed.

Pneumatic ash removal material sealing pump

Pneumatic ash removal material sealing pumpthe principle is simple.Using the high-speed airflow generated by the nozzle, a negative pressure area is formed, thereby ejecting powder materials into the pump body. This ejector action enables the powder material to be carried by the airflow and transported.,It is a product series that integrates Long-distance or complex terrain material transportation, System supporting use, Dust control, Raw material transportation and Waste disposal。

Related recommendation

-

What is a Vacuum rotary discharger? How much is the price of the unloader?

2025-5-26 -

Introduction to Gravity dust removal ash conveying, introduction to Powder conveying advantages and characteristics

2025-5-26 -

What is a Aluminum hydroxide powder pneumatic conveying system? Introduction to the advantages and characteristics of Pneumatic conveying equipment functions

2025-5-26 -

What is a Medium pressure roots vacuum pump? How much is the price of the the roots vacuum pump?

2025-5-26 -

What is a Pneumatic conveying of rare earth crystal powder? Introduction to the Working Principle of Powder pneumatic conveying

2025-5-26 -

What is a Straw powder conveying equipment? Introduction to the advantages and characteristics of Pneumatic conveying equipment functions

2025-5-26 -

Introduction to Bulk cement pneumatic conveying, pneumatic conveying system specifications, model parameters

2025-5-26 -

Introduction to Coal ash conveying equipment and Pneumatic conveying equipment structure principle

2025-5-26 -

Introduction to Air-driven material sealing pump, how much is the price of the Material seal pump?

2025-5-26 -

What is a Printing factory Roots blower? Introduction to the advantages and characteristics of the blower

2025-5-26