Introduction to Air-driven material sealing pump, how much is the price of the Material seal pump?

Air-driven material sealing pumpIt is a new type of pneumatic conveying equipment for powder, which belongs to the category of low-pressure dilute phase conveying, and mainly uses the ejector effect of high-speed airflow to convey powder materials.,it is an ideal choice for customers to buy Air-driven material sealing pump。

1、Brief introduction of Air-driven material sealing pump

Air-driven material sealing pumpIt is a kind of powder pneumatic conveying equipment.。

Air-driven material sealing pump

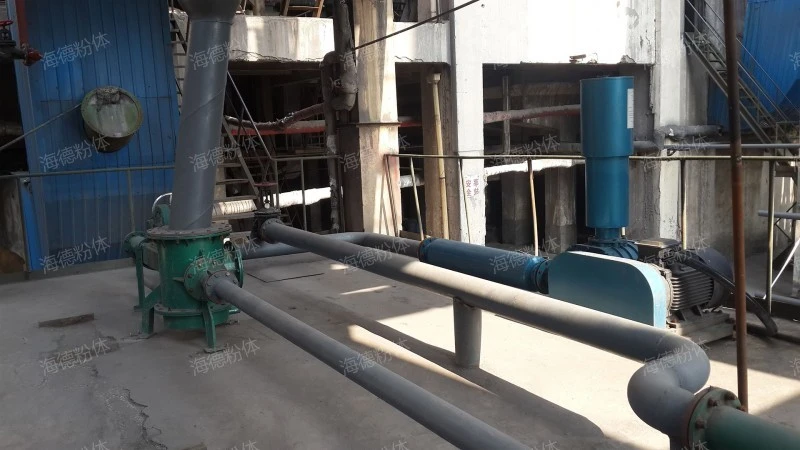

2、On-site real shot of Air-driven material sealing pump

Take a look at the beautiful pictures of the Air-driven material sealing pump, showing the product style.。

Air-driven material sealing pump

Note: All the pictures in this article were taken by hyde powder manufacturer.。

3、Air-driven material sealing pump advantage

The advantages of Air-driven material sealing pump are as follows:

- Simple structure and convenient operation

- Low pressure transportation, little wear and tear.

- Completely sealed and pollution-free.

- regulate automatically

- Low pressure transportation, little wear and tear.

The Air-driven material sealing pump has simple structure, convenient operation and small maintenance.

The Air-driven material sealing pump adopts low-pressure conveying mode, and the pressure of ash conveying medium is low, so the equipment pipes and valves are not easy to wear and prolong the service life.

The low positive pressure and fully sealed conveying mode is adopted, which ensures that the powder will not leak to the external environment during the conveying process and meets the environmental protection requirements.

It can automatically adjust the output to achieve good ash conveying effect.

The pressure of ash conveying medium is low, the valve of equipment pipeline is not easy to wear and has long service life.

Air-driven material sealing pump

4、Air-driven material sealing pump function

Air-driven material sealing pumpit has the functions of Conveying of powdery materials, Dust control, Waste disposal, System supporting use and Raw material transportation。

Air-driven material sealing pump

5、Air-driven material sealing pump structure composition

The Air-driven material sealing pump structure is introduced as follows:

- sealing device

- Feed port and discharge port

- injector

- Bottom vaporization device

- Cylindrical pump body

The sealing device is an important part in the Air-driven material sealing pump, which is used to ensure the tightness inside the pump body and prevent the leakage of airflow and powder. The design and manufacture of sealing device need to consider the factors such as wear resistance, corrosion resistance and sealing performance.

The inlet is used to add powder materials into the Air-driven material sealing pump, and the outlet is responsible for discharging the transported powder materials. The design of inlet and outlet needs to consider the fluidity, sealing and easy cleaning of powder.

Nozzle is one of the key parts of the Air-driven material sealing pump, which is responsible for generating high-speed airflow and ejecting powder materials for transportation. The design and manufacturing accuracy of the nozzle have an important influence on the performance of the Air-driven material sealing pump.

The bottom vaporizing device is an optional component in the Air-driven material sealing pump. It vaporizes the powder at the bottom of the pump body by steam or other vaporizing media to reduce the friction and wear between the powder and the pump body and improve the smoothness and efficiency of transportation.

The cylindrical pump body is the main part of the Air-driven material sealing pump, which contains the nozzle and powder materials, and provides the necessary space for air flow and powder to be mixed and transported. The material and structure design of the pump body need to consider the factors such as wear resistance, corrosion resistance and sealing.

Air-driven material sealing pump

6、High-definition map of hyde workshop

The finished products of the Air-driven material sealing pump factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

hyde powder

The finished products of the Air-driven material sealing pump factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Air-driven material sealing pumpis a popular Air-driven material sealing pump,Using low-pressure conveying mode, the pressure of ash conveying medium is low, so the equipment pipes and valves are not easy to wear and prolong the service life.、Compared with the traditional mechanical conveying mode, the pneumatic conveying mode has higher energy efficiency ratio and lower energy consumption. The fully sealed design also reduces dust emission and is beneficial to environmental protection.、It can be flexibly arranged and configured according to the specific conditions of the system to meet the transportation needs of different projects. Pipes can be arranged horizontally, vertically and obliquely, which is suitable for all kinds of complicated transportation scenes.、Can be flexibly arranged and configured according to the specific situation of the system.、It can be transported continuously, and the output of equipment can be automatically adjusted to achieve good ash conveying effect.。

Related recommendation

-

Introduction to Automatic negative pressure pneumatic conveying equipment and Powder pneumatic conveying structure principle

2025-5-26 -

Introduction to Methyl cellulose transportation, introduction to pneumatic conveying function advantages and characteristics

2025-5-26 -

Introduction to Anti-blocking unloader, unloader specifications, model parameters

2025-5-26 -

What is a Soy protein powder conveying equipment? Material conveying specifications, models, and parameters

2025-5-26 -

What is a Bentonite pneumatic conveying equipment? Introduction to the advantages, characteristics, and principles of the pneumatic conveying system

2025-5-26 -

Introduction to Sulfur powder transportation and Powder pneumatic conveying working principle

2025-5-26 -

Introduction to Polymer denitrification, introduction to Material conveying function advantages and characteristics

2025-5-26 -

What is a Corn bran transportation? Introduction to the advantages and characteristics of Powder pneumatic conveying functions

2025-5-26 -

Introduction to Bread powder conveying system, pneumatic conveying advantages, characteristics and principles

2025-5-26 -

What is a Ton bag unpacking and conveying equipment? pneumatic conveying specifications, models, and parameters

2025-5-26