What is a Continuous normalizing heat treatment furnace? Introduction to the advantages and characteristics of heating furnace functions

Continuous normalizing heat treatment furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,it has the functions of quench, Casting heating, heat treatment, temper and normalizing,Widely used in Metal heat treatment, Metal forging heating, Energy conservation and environmental protection, Metal melting and casting and Metal melting and casting,it has the characteristics of energy-efficient, Stable and reliable, energy saving and environmental protection, Easy to control and Easy to maintain,it is an ideal choice for customers to buy Continuous normalizing heat treatment furnace。The following is to introduce the Continuous normalizing heat treatment furnace:

1、Brief introduction of Continuous normalizing heat treatment furnace

Continuous normalizing heat treatment furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,is a Continuous normalizing heat treatment furnace,it has been widely used in electron, Household necessities, material, shipping, surface treatment and other industries,The overall structural design is relatively simple and compact.,it is mainly composed of furnace chamber, Radiation chamber, ventilation system, convection chamber and combustor,be loved by our customers.。

Continuous normalizing heat treatment furnace

2、Continuous normalizing heat treatment furnace function

Continuous normalizing heat treatment furnacemultifunctional, with functions such as Forging heating, temper, Forging heating, anneal and hardening and tempering,the product looks atmospheric.,Mainly used forMetal forging heating,Metal tempering,Metal heat treatment,Improve production efficiency andEnergy conservation and environmental protection,was developed and designed by One-combustion energy saving。

Continuous normalizing heat treatment furnace

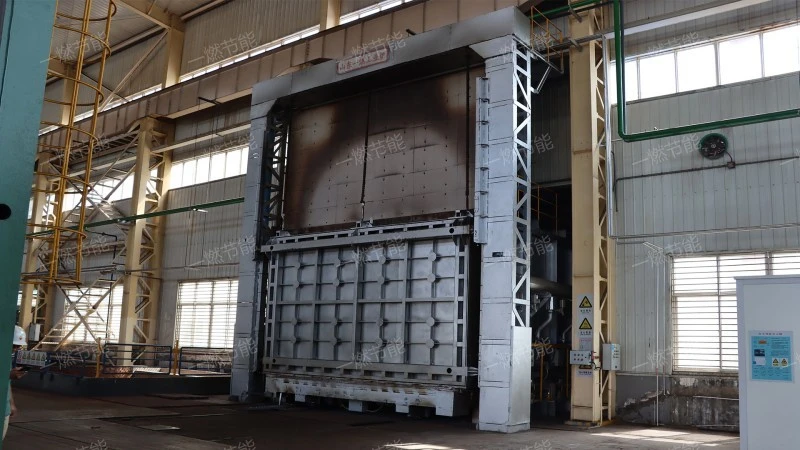

3、Continuous normalizing heat treatment furnace working site

You can buy Continuous normalizing heat treatment furnace according to your needs and show you product videos.。

Continuous normalizing heat treatment furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd It is mostly used in Metal melting and casting, Metal heat treatment, Metal tempering, Metal forging heating, Improve production efficiency, Energy conservation and environmental protection and so on。

4、Structural characteristics of Continuous normalizing heat treatment furnace

The Continuous normalizing heat treatment furnace structure is introduced as follows:

- convection chamber

- Waste heat recovery system

- convection chamber

- Radiation chamber

- Waste heat recovery system

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The material is heated by convection heat transfer of high temperature flue gas discharged from the radiation chamber. Flue gas washes the tube wall of the furnace tube at a high speed to carry out effective convection heat transfer, and its heat load accounts for about 20%-30% of the whole furnace. The convection chamber is generally arranged above the radiation chamber, and some are placed on the ground alone. In order to improve the heat transfer effect, nail head tubes or finned tubes are often used in furnace tubes.

The heat load of the main place for Continuous normalizing heat treatment furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

Continuous normalizing heat treatment furnace

5、How much is the Continuous normalizing heat treatment furnace?

The Continuous normalizing heat treatment furnace price is introduced as follows:

- raw material

- Company size

- Model specification

- product costs

- technology content

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

Although there are many manufacturers of products in Jinan, Shandong province, there are certain differences in the scale and strength of each manufacturer. Some manufacturers are large in scale and strength, some are small in scale, and some manufacturers do not have their own production workshops and belong to middlemen. Relatively speaking, the prices of products formulated by middlemen are higher.

With different specifications, the basic configuration of products will be different, and the price of products with high configuration will naturally be higher, otherwise the price will be lower, so there is a close relationship between specifications and prices.

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. One-combustion energy saving has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

Continuous normalizing heat treatment furnace

6、One-combustion energy saving workshop picture real shot

The finished products of the Continuous normalizing heat treatment furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Continuous normalizing heat treatment furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Continuous normalizing heat treatment furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,at runtime,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,the product looks beautiful.。

Related recommendation

-

What is a High temperature ring roasting furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

What is a Deep well spheroidization annealing furnace? heating furnace specifications, models, and parameters

2025-5-27 -

Introduction to Roller bottom mold heating furnace and forging furnace structure principle

2025-5-27 -

What is a Step by step continuous heating furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

What is a Roller bottom industrial furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a Resistance heating furnace for steel billets? Introduction to the Working Principle of Trolley resistance furnace

2025-5-27 -

What is a Side in side out heating furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to Explosion proof well type annealing furnace, forging furnace specifications, model parameters

2025-5-27 -

What is a Chain iron core annealing furnace? How much is the price of the forging furnace?

2025-5-27 -

Introduction to Regenerative heat treatment chain furnace, forging furnace specifications, model parameters

2025-5-27