Introduction to Continuous bright heat treatment industrial furnace and Forging furnace structure principle

Continuous bright heat treatment industrial furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,the product looks beautiful.。

1、Brief introduction of Continuous bright heat treatment industrial furnace

Continuous bright heat treatment industrial furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,structure mainly includes: furnace chamber, combustor, recovery of waste heat, Radiation chamber, Radiation chamber and so on,it is widely used in Machinery manufacturing, war industry, material, war industry and heat treatment,Commonly used inMetal tempering,Metal forging heating,Metal melting and casting,Energy conservation and environmental protection,Metal melting and casting and so on,is a Continuous bright heat treatment industrial furnace newly developed by One-combustion energy saving。

Continuous bright heat treatment industrial furnace

2、Introduction of advantages of Continuous bright heat treatment industrial furnace

Continuous bright heat treatment industrial furnaces have the following advantages.

- Efficient combustion

- Wide application range

- Reduce operating costs

- Multiple fuel options

- Efficient combustion

The Continuous bright heat treatment industrial furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

The Continuous bright heat treatment industrial furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

The efficient combustion and waste heat recovery system of the Continuous bright heat treatment industrial furnace can significantly reduce energy consumption, thus reducing operating costs.

Although the Continuous bright heat treatment industrial furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

The Continuous bright heat treatment industrial furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

Continuous bright heat treatment industrial furnace

3、Continuous bright heat treatment industrial furnace principle

Continuous bright heat treatment industrial furnaceat runtime,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,Cheap and high quality。

Continuous bright heat treatment industrial furnace

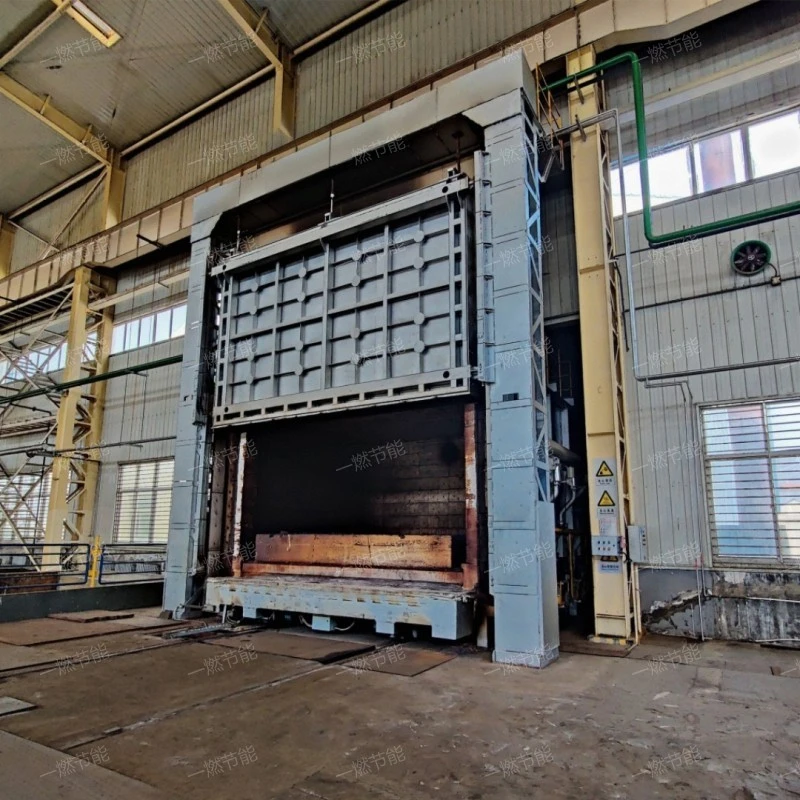

4、Continuous bright heat treatment industrial furnace work site real shot

High-definition pictures of reliable Continuous bright heat treatment industrial furnace at a glance。

Continuous bright heat treatment industrial furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Advantages of Continuous bright heat treatment industrial furnace principle

Continuous bright heat treatment industrial furnacethe principle is simple.The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.。

Continuous bright heat treatment industrial furnace

Continuous bright heat treatment industrial furnacethe product looks beautiful.,is a Continuous bright heat treatment industrial furnace,at the start of the operation,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.。

Related recommendation

-

Introduction to Quenched and tempered well type quenching furnace and forging furnace advantages and features

2025-5-27 -

Introduction to High temperature tempering furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

What is a Ceramic fiber electric furnace? How much is the price of the Trolley electric furnace?

2025-5-27 -

Introduction to Automated trolley furnace and Forging furnace working principle

2025-5-27 -

Introduction to Side opening natural gas trolley furnace and heating furnace working principle

2025-5-27 -

Introduction to Natural gas regenerative through furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Heating furnace for trolley in heat treatment workshop, heating furnace specifications, model parameters

2025-5-27 -

Introduction to Segmented annealing furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Continuous Annealing Heating Furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Environmentally friendly through forging furnace and Forging furnace structure principle

2025-5-27