Introduction to Intermittent heating furnace, Forging furnace specifications, model parameters

Intermittent heating furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.。The following is to introduce the Intermittent heating furnace:

1、Brief introduction of Intermittent heating furnace

Intermittent heating furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.。

Intermittent heating furnace

2、Intermittent heating furnace application

Intermittent heating furnaces have the following purposes.

- Metal tempering

- Metal heat treatment

- Metal heat treatment

- Metal tempering

- Metal melting and casting

By properly heating and cooling the metal material, the Intermittent heating furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

In addition to forging heating, Intermittent heating furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

In addition to forging heating, Intermittent heating furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the Intermittent heating furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

Although it is mainly used for forging heating, some types of Intermittent heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

Intermittent heating furnace

3、Intermittent heating furnace explanation video

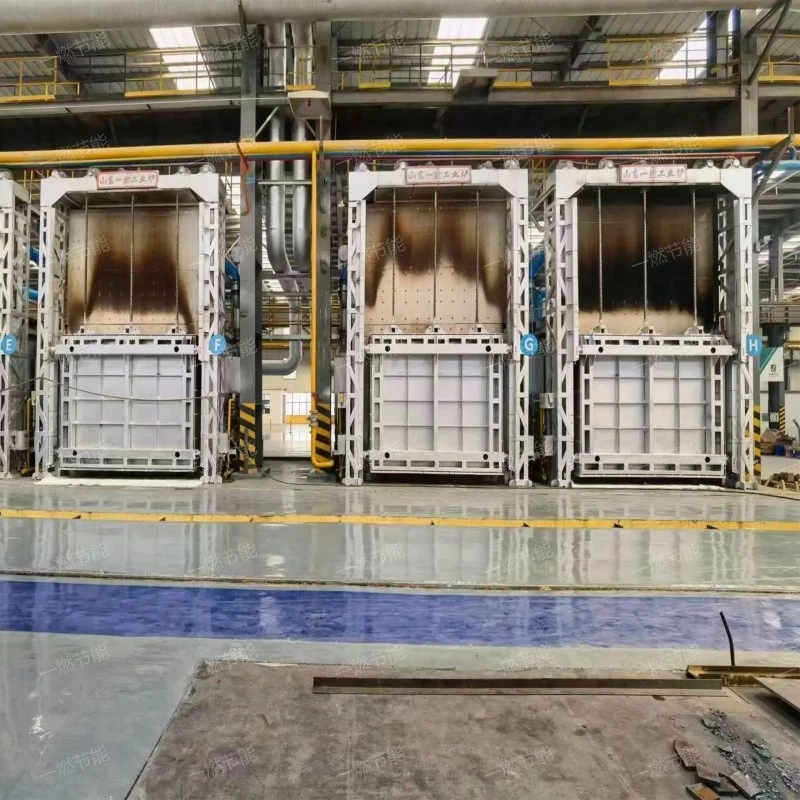

The following is the live video of Intermittent heating furnace designed and produced by One-combustion energy saving for users, from which we can see the the advantage is Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency. of Intermittent heating furnace.。

Intermittent heating furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd is a popular Intermittent heating furnace。

4、Introduction of Intermittent heating furnace characteristics

Intermittent heating furnace has the following characteristics

- Stable and reliable

- Strong adaptability

- Easy to maintain

- Easy to control

- Strong adaptability

The Intermittent heating furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Intermittent heating furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The structural design of the Intermittent heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The combustion system and ventilation system of the Intermittent heating furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Intermittent heating furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

Intermittent heating furnace

5、How much is the Intermittent heating furnace?

The Intermittent heating furnace price is introduced as follows:

- Low cost of raw materials

- deploy

- quality

- Service factor

- product function

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. One-combustion energy saving has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

The difference in Intermittent heating furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

The higher the quality of the product, the longer its service life will be, and such products can create more amazing economic value for customers as much as possible. At the same time, customers are quite fond of such products, and One-combustion energy saving's product quality is guaranteed and the price is cost-effective.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Intermittent heating furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Intermittent heating furnace price can meet the purchasing needs of customers.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Intermittent heating furnace

6、Company preferential activities

Intermittent heating furnace is a new type of Forging furnace introduced by Shandong yiran energy-saving environment protection co., ltd manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for surface treatment and other industries. Now consult One-combustion energy savingIntermittent heating furnace, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

One-combustion energy saving

Intermittent heating furnacemultifunctional, with functions such as Forging heating, Forging heating, anneal, quench and temper,it can be used in machinery, pharmacy, war industry, aerospace, Machinery manufacturing and other industries,Widely used inImprove production efficiency,Metal forging heating,Metal melting and casting,Metal tempering,Metal heat treatment and so on。

Related recommendation

-

What is a Adjustable heat treatment industrial furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Double pass tempering furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

回火台车炉

2023-08-26 -

Introduction to Circular Well Annealing Furnace and forging furnace structure principle

2025-5-27 -

What is a Ring trolley forging furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

Introduction to Low temperature tube roasting furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Gas through furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

台车快速淬火炉

2023-05-24 -

What is a Energy saving step heating furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

Introduction to Steel pipe annealing natural gas trolley furnace and heating furnace structure principle

2025-5-27