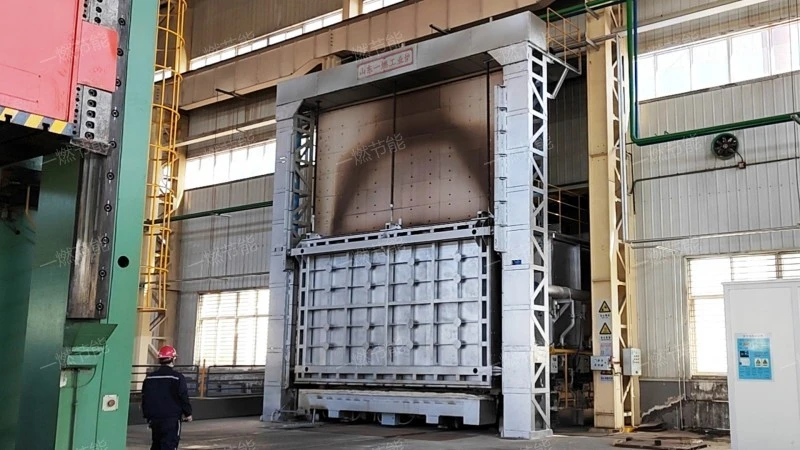

High temperature circulating trolley furnace detailed introduction

High temperature circulating trolley furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,it is widely used in chemical industry, metallurgy, surface treatment, Household necessities, pharmacy and other industries,is designed by One-combustion energy saving with advanced technology。The following is to introduce the High temperature circulating trolley furnace:

1、Brief introduction of High temperature circulating trolley furnace

High temperature circulating trolley furnaceIt is a forging heating device using gas as fuel.,is carefully developed by One-combustion energy saving combined with advanced technology。

High temperature circulating trolley furnace

2、Functional advantages of High temperature circulating trolley furnace

High temperature circulating trolley furnaces have the following advantages.

- Rapid temperature rise

- Wide application range

- Intelligent control

- Uniform heating

- Improve product quality

The High temperature circulating trolley furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

The High temperature circulating trolley furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

The High temperature circulating trolley furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

The High temperature circulating trolley furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

Because the High temperature circulating trolley furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

High temperature circulating trolley furnace

3、Introduction of High temperature circulating trolley furnace characteristics

High temperature circulating trolley furnace has the following characteristics

- Easy to control

- Stable and reliable

- Easy to control

- energy saving and environmental protection

- Efficient heating

The combustion system and ventilation system of the High temperature circulating trolley furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The High temperature circulating trolley furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The combustion system and ventilation system of the High temperature circulating trolley furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some High temperature circulating trolley furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

The High temperature circulating trolley furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

High temperature circulating trolley furnace

4、High temperature circulating trolley furnace function

High temperature circulating trolley furnaceit has the functions of Forging heating, temper, quench, Casting heating and heat treatment,usually used in building materials, aerospace, chemical industry, electron, heat treatment and other fields,Structure consists of ventilation system, furnace chamber, convection chamber, recovery of waste heat, ventilation system and so on,productThe structural design is simple, novel and special.,the product looks atmospheric.,favorable price。

High temperature circulating trolley furnace

5、High temperature circulating trolley furnace structure composition

The High temperature circulating trolley furnace has the following structure

- ventilation system

- Waste heat recovery system

- Waste heat recovery system

- furnace chamber

- convection chamber

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

A space for holding metallic materials for heating.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

High temperature circulating trolley furnace

6、How much is the High temperature circulating trolley furnace?

The High temperature circulating trolley furnace price is introduced as follows:

- select a qualified person

- Low cost of raw materials

- quality

- regional difference

- Product configuration difference

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

Product manufacturers are different, and the cost spent by each manufacturer in producing products is definitely different. The higher the cost of producing products, the higher the price of products set by manufacturers. On the contrary, the High temperature circulating trolley furnace price is low.

The High temperature circulating trolley furnace is made of high-quality materials, and the cost of the product is high, so the price of the product will also rise. One-combustion energy saving has always adhered to high quality in the construction of High temperature circulating trolley furnace and won the trust of customers.

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of High temperature circulating trolley furnace are closely related. One-combustion energy saving has comprehensively measured the configuration and sales price of products when designing High temperature circulating trolley furnace, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

High temperature circulating trolley furnace

High temperature circulating trolley furnaceIt has the functions of Metal forging heating, Energy conservation and environmental protection, Improve production efficiency, Metal forging heating and Metal heat treatment,is a popular High temperature circulating trolley furnace,the product looks atmospheric.。

Related recommendation

-

Introduction to Gas storage through forging heating furnace and Forging furnace working principle

2025-5-27 -

What is a Automatic temperature control chain heat treatment furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Preheating heating furnace, Forging furnace specifications, model parameters

2025-5-27 -

What is a Isothermal annealing heat treatment furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Casting resistance heating furnace, advantages, characteristics and principles of Trolley resistance furnace

2025-5-27 -

What is a Rapid heating furnace box type? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

Introduction to Stepped bottom pipeline heating furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

What is a Trolley type solid solution furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

What is a Two end high-temperature trolley forging furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

台车式铝合金炉

2023-07-13