Introduction to Industrial quenching furnace flue gas denitrification system, SCR denitration system specifications, model parameters

Industrial quenching furnace flue gas denitrification systemit refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.。The following is to introduce the Industrial quenching furnace flue gas denitrification system:

1、Brief introduction of Industrial quenching furnace flue gas denitrification system

Industrial quenching furnace flue gas denitrification systemdelective catalytic reduction technology is an efficient flue gas denitrification technology.,it has the functions of Improve working conditions, Promote sustainable development, Improve working conditions, Promote sustainable development and Improve energy efficiency,is a common Industrial quenching furnace flue gas denitrification system,widely used in cement plant, metallurgy, coal-fired power station, Gas power plant, coal-fired power station and other fields,It has a wide range of uses, and is often used inenvironmental protection,Flue gas denitrification,Promote sustainable development,environmental protection,Flue gas denitrification and so on。

Industrial quenching furnace flue gas denitrification system

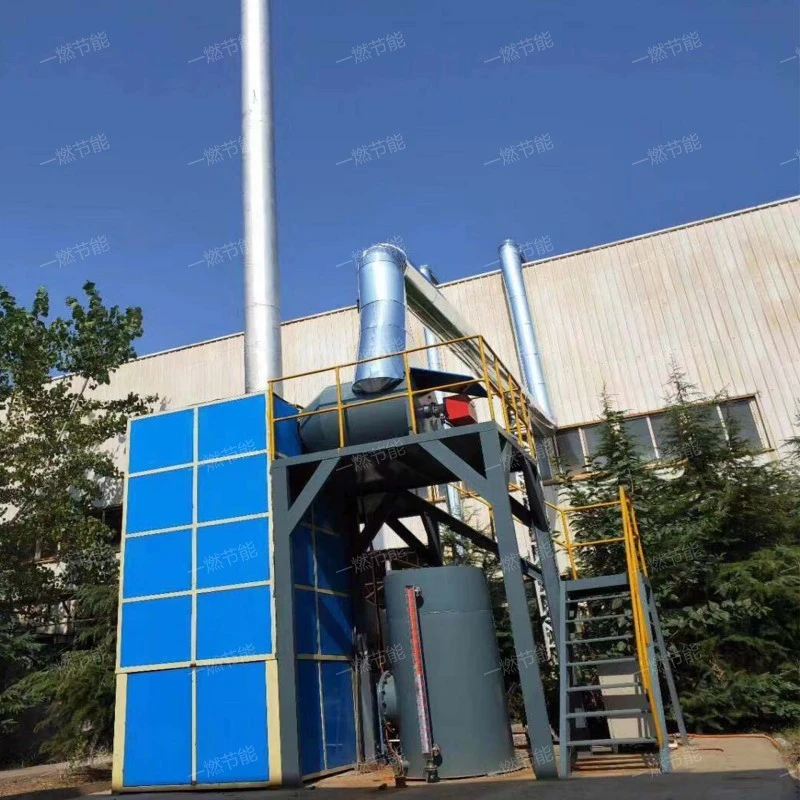

2、Physical picture of Industrial quenching furnace flue gas denitrification system

Beautiful design, excellent material selection and excellent quality.。

Industrial quenching furnace flue gas denitrification system

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Industrial quenching furnace flue gas denitrification system structure

The Industrial quenching furnace flue gas denitrification system structure is introduced as follows:

- Reducing agent storage and supply system

- Reactor

- Reducing agent supply

- control system

- Temperature control and monitoring

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

It is the core component of Industrial quenching furnace flue gas denitrification system technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

Reducing agents such as liquid pure ammonia or ammonia water (aqueous solution of ammonia) are evaporated and mixed with diluted air or flue gas.

The whole Industrial quenching furnace flue gas denitrification system is automatically controlled to ensure the stable operation of the system and achieve the expected denitration effect.

The temperature in the catalyst reactor is maintained within the optimal reaction temperature range through the temperature control and monitoring system.

Industrial quenching furnace flue gas denitrification system

4、Industrial quenching furnace flue gas denitrification system function

Industrial quenching furnace flue gas denitrification systemmultifunctional, with functions such as environmental protection, Improve working conditions, Improve energy efficiency, Promote sustainable development and environmental protection,is based on One-combustion energy saving is a kind of Industrial quenching furnace flue gas denitrification system manufactured by One-combustion energy saving。

Industrial quenching furnace flue gas denitrification system

5、Structural characteristics of Industrial quenching furnace flue gas denitrification system

The Industrial quenching furnace flue gas denitrification system structure is introduced as follows:

- Reducing agent supply

- Reactor

- control system

- Reducing agent storage and supply system

- Flue gas mixing and distribution system

Reducing agents such as liquid pure ammonia or ammonia water (aqueous solution of ammonia) are evaporated and mixed with diluted air or flue gas.

It is the core component of Industrial quenching furnace flue gas denitrification system technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

The whole Industrial quenching furnace flue gas denitrification system is automatically controlled to ensure the stable operation of the system and achieve the expected denitration effect.

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

Ensure that the flue gas and reducing agent are fully mixed in the reactor to improve the denitrification efficiency.

Industrial quenching furnace flue gas denitrification system

6、Industrial quenching furnace flue gas denitrification system price concessions

The Industrial quenching furnace flue gas denitrification system price is introduced as follows:

- raw material

- product function

- Product technology

- regional advantages

- product function

The higher the cost of materials, the higher the price will be. In the process of purchasing products, users need to make a detailed understanding of the materials selected for products.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

One-combustion energy saving address:Jinan, Shandong province, the transportation here is developed and convenient, and the products can be transported to the designated place in a short time, which saves customers a sum of transportation expenses.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Industrial quenching furnace flue gas denitrification system

Industrial quenching furnace flue gas denitrification systemMainly used forMeet the requirements of environmental protection,Improve product quality,environmental protection,Meet the requirements of environmental protection andPromote sustainable development,is a kind of high quality and low price Industrial quenching furnace flue gas denitrification system。

Related recommendation

-

Introduction to Double chamber heating furnace, Forging furnace specifications, model parameters

2025-5-27 -

Introduction to Electric heating bright annealing furnace and Trolley resistance heating furnace structure principle

2025-5-27 -

Introduction to Heat treatment resistance heating furnace, advantages, characteristics and principles of Trolley resistance furnace

2025-5-27 -

What is a Aluminum ingot heating furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

What is a Explosion proof well furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to High temperature tempering furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

What is a Side entry and side exit walking furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to High temperature forging furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Stepping bottom hybrid heating furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

What is a Burner direct heating furnace? Introduction to the principle of heating furnace structure

2025-5-27