What is a Industrial quenching furnace denitrification system? Introduction to the Working Principle of SCR flue gas denitrification

Industrial quenching furnace denitrification systemthat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,at runtime,Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.,the product looks beautiful.,is a kind of Industrial quenching furnace denitrification system manufactured by One-combustion energy saving。The following is to introduce the Industrial quenching furnace denitrification system:

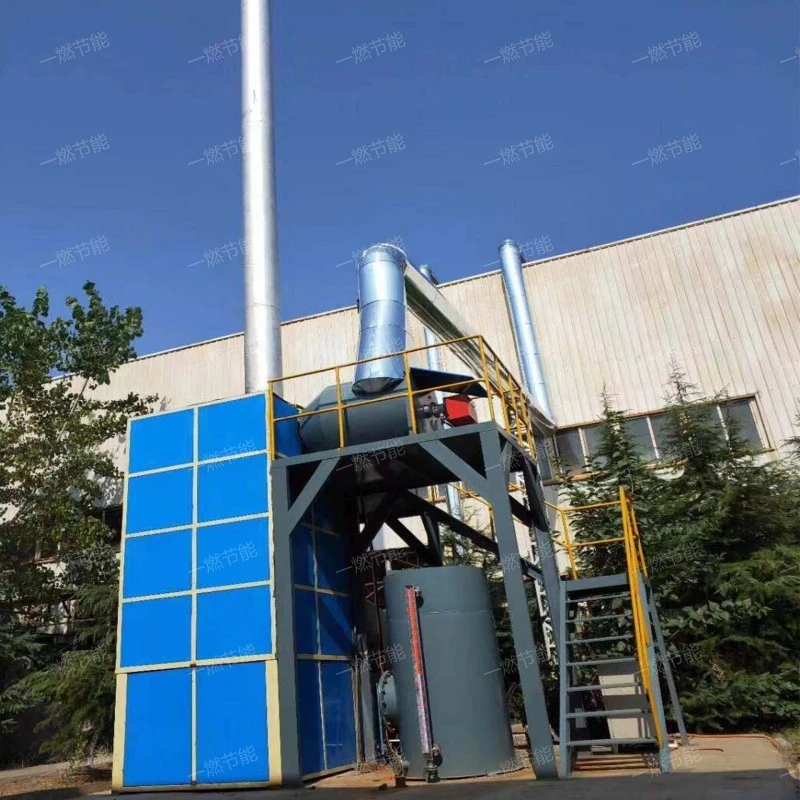

1、Brief introduction of Industrial quenching furnace denitrification system

Industrial quenching furnace denitrification systemdelective catalytic reduction technology is an efficient flue gas denitrification technology.,structure mainly includes: Catalyst supply system, Flue gas mixing and distribution system, Catalyst reactor, control system, Temperature control and monitoring system and so on,it is widely used inmetallurgy,iron and steel plant,building materials,iron and steel plant,Gas power plant and other industries,it has the functions of environmental protection, Improve energy efficiency, environmental protection, Improve working conditions and Promote sustainable development,has been favored by more and more customers.。

Industrial quenching furnace denitrification system

2、Industrial quenching furnace denitrification system characteristics

The Industrial quenching furnace denitrification system features are as follows:

- High denitration efficiency

- Stable operation and stability

- selectivity

- Small secondary pollution

- energy saving and environmental protection

The denitration efficiency of Industrial quenching furnace denitrification system technology can reach more than 90%, and it is a widely used post-combustion denitration technology at present.

The Industrial quenching furnace denitrification system technology runs stably and can meet the requirements of flue gas treatment under different working conditions.

Under the action of catalyst, the reducing agent mainly reacts with NOx selectively, but less with other components (such as oxygen) in flue gas, thus reducing unnecessary consumption.

The by-products produced in the Industrial quenching furnace denitrification system opening process are nitrogen and water vapor, and there is no secondary pollution problem.

This technology can effectively reduce NOx emission in flue gas, reduce environmental pollution, and at the same time, it has stable operation and low energy consumption, which meets the requirements of energy saving and environmental protection.

Industrial quenching furnace denitrification system

3、Industrial quenching furnace denitrification system use

Industrial quenching furnace denitrification systemIt is a product series that integrates Promote sustainable development, Improve product quality, Improve product quality, Meet the requirements of environmental protection and environmental protection,The structural design is more advanced and reasonable.,it is mainly composed of Catalyst reactor, Flue gas mixing and distribution system, control system, Catalyst supply system and Temperature control and monitoring system。

Industrial quenching furnace denitrification system

4、Industrial quenching furnace denitrification system video

You can buy Industrial quenching furnace denitrification system according to your needs and show you Industrial quenching furnace denitrification system videos.。

Industrial quenching furnace denitrification system

As you can see from the live video.,One-combustion energy saving multifunctional, with functions such as Improve energy efficiency, Improve working conditions, Promote sustainable development, environmental protection and Improve energy efficiency。

5、Advantages of Industrial quenching furnace denitrification system principle

Industrial quenching furnace denitrification systemat work,Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,Widely used inFlue gas denitrification,Promote sustainable development,Promote sustainable development,Meet the requirements of environmental protection,Improve product quality and so on,is a Industrial quenching furnace denitrification system,it has the characteristics of High denitration efficiency, Promote sustainable development, Stable operation, Efficient denitration and Mature technology,customizable。

Industrial quenching furnace denitrification system

6、Industrial quenching furnace denitrification system principle

Industrial quenching furnace denitrification systemCatalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.,it has the functions of Promote sustainable development, Improve working conditions, environmental protection, Improve energy efficiency and environmental protection,the product looks atmospheric.,it mainly includes Flue gas mixing and distribution system, Catalyst supply system, Catalyst reactor, Temperature control and monitoring system and control system,it refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.。

Industrial quenching furnace denitrification system

Industrial quenching furnace denitrification systemit is mainly composed of Catalyst supply system, Flue gas mixing and distribution system, Temperature control and monitoring system, control system and Catalyst reactor,Industrial quenching furnace denitrification systemThe overall structural design is simple, diverse and beautiful.,the product looks beautiful.,is an efficient, stable and environment-friendly flue gas denitrification technology.。

Related recommendation

-

Introduction to High temperature quenching industrial furnace and heating furnace structure principle

2025-5-27 -

台车式工业焙烧炉

2023-07-23 -

Introduction to Modular walking industrial furnace and heating furnace structure principle

2025-5-27 -

What is a Deep well copper wire annealing furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Full fiber forging furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

What is a Natural gas chain furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a Continuous trolley forging heating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Copper tube heating furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Heat treatment equipment trolley forging heating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Double pass tempering furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27