What is a Denitrification of flue gas from roasting furnace? SCR flue gas denitrification specifications, models, and parameters

Denitrification of flue gas from roasting furnaceit refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.,Commonly used inImprove product quality,Promote sustainable development,Improve product quality,Promote sustainable development,Flue gas denitrification and so on,it is mainly composed of Flue gas mixing and distribution system, Catalyst reactor, Catalyst supply system, control system and Temperature control and monitoring system,Denitrification of flue gas from roasting furnaceSimple structure and advanced technology.。The following is to introduce the Denitrification of flue gas from roasting furnace:

1、Brief introduction of Denitrification of flue gas from roasting furnace

Denitrification of flue gas from roasting furnacethat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.。

Denitrification of flue gas from roasting furnace

2、Structural characteristics of Denitrification of flue gas from roasting furnace

The Denitrification of flue gas from roasting furnace structure is introduced as follows:

- Reducing agent storage and supply system

- Flue gas mixing and distribution system

- Reactor

- Reducing agent storage and supply system

- control system

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

Ensure that the flue gas and reducing agent are fully mixed in the reactor to improve the denitrification efficiency.

It is the core component of Denitrification of flue gas from roasting furnace technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

The whole Denitrification of flue gas from roasting furnace is automatically controlled, including the adjustment of reducing agent supply, flue gas flow and temperature, so as to ensure the stable operation of the system and achieve the expected denitrification effect.

Denitrification of flue gas from roasting furnace

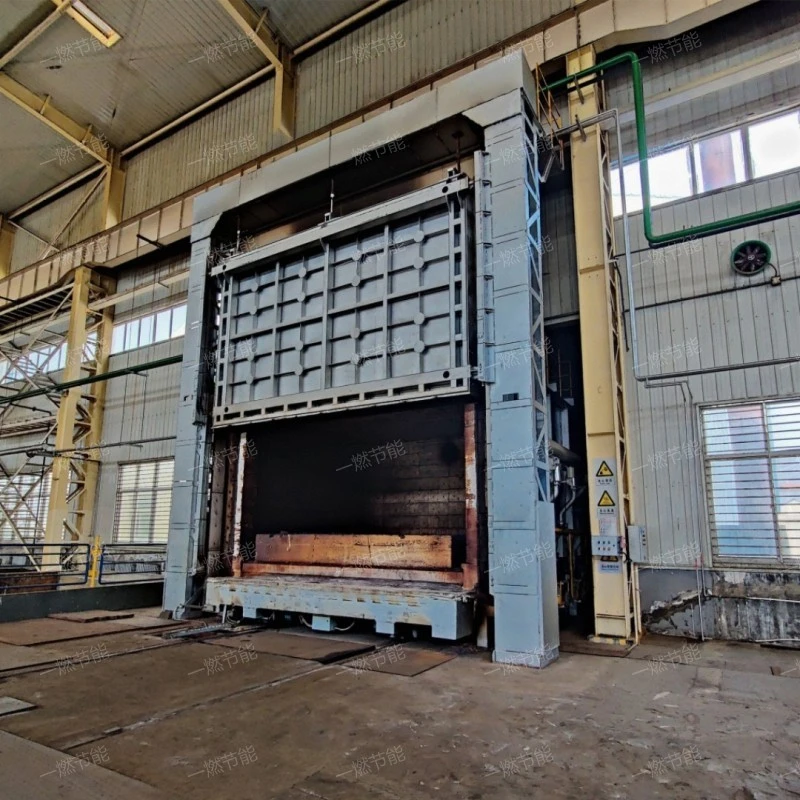

3、Denitrification of flue gas from roasting furnace field real shot

Speak directly with facts on the spot。

Denitrification of flue gas from roasting furnace

As you can see from the live video.,One-combustion energy saving structure mainly includes: Flue gas mixing and distribution system, Catalyst reactor, Catalyst supply system, control system, Temperature control and monitoring system and so on,productThe structure is novel, special, advanced, reasonable and scientific.。

4、Denitrification of flue gas from roasting furnace use

Denitrification of flue gas from roasting furnaceWidely used in environmental protection, Meet the requirements of environmental protection, Improve product quality, Promote sustainable development and Meet the requirements of environmental protection,features include High denitration efficiency, Promote sustainable development, Mature and stable technology, energy saving and environmental protection and Environment friendly,at work,Ammonia gas or other suitable reducing agent (such as urea aqueous solution) is sprayed into the flue gas upstream of the catalyst at high temperature. Under the action of catalyst, the reducing agent selectively reacts with nitrogen oxides (NOx) in flue gas to generate pollution-free nitrogen and water vapor. Because NH3 is selective, it only reacts with NOx and basically does not react with O2, so this technology is called selective catalytic reduction denitrification.。

Denitrification of flue gas from roasting furnace

5、How much is the Denitrification of flue gas from roasting furnace?

The Denitrification of flue gas from roasting furnace price is introduced as follows:

- Different regions

- product quality

- Low cost of raw materials

- select a qualified person

- Proper management mode

Different provinces and regions have different consumption levels, different market positioning and different prices.

The service life of products with excellent quality will be longer, and at the same time, such products are very high in science and technology, which will create higher benefits for customers and make the price generally high, which is the main reason for the high price.

One-combustion energy saving has a large production scale, strong manufacturing strength and high degree of automation in product production. In such a manufacturing environment, the cost of manufacturing Denitrification of flue gas from roasting furnace in One-combustion energy saving is greatly reduced.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

There are direct selling manufacturers and agents in the market. Agents are higher than direct selling manufacturers, mainly because agents get goods from manufacturers, sell them to customers and earn the difference from middlemen, so the natural price is higher.

Denitrification of flue gas from roasting furnace

6、One-combustion energy saving workshop real shot

The finished products of the Denitrification of flue gas from roasting furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Denitrification of flue gas from roasting furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Denitrification of flue gas from roasting furnaceIt is a product series that integrates environmental protection, Flue gas denitrification, Flue gas denitrification, Improve product quality and Promote sustainable development,the full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.。

Related recommendation

-

Introduction to Low temperature catalyst flue gas denitrification, how much is the price of the SCR flue gas denitrification?

2025-5-27 -

What is a Car baking furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Natural gas regenerative trolley forging furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Environmentally friendly step-by-step heat treatment furnace and forging furnace advantages and features

2025-5-27 -

等温热处理生产线

2023-03-31 -

Introduction to High temperature well tube furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Medium temperature trolley furnace in casting and forging plant, advantages, characteristics and principles of Forging furnace

2025-5-27 -

What is a SCR low temperature flue gas denitrification? How much is the price of the SCR denitration system?

2025-5-27 -

What is a Dual car carbonization furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Low temperature absorption SCR flue gas denitrification equipment and SCR denitration system advantages and features

2025-5-27