Introduction to Deep well isothermal quenching furnace and Forging furnace working principle

Deep well isothermal quenching furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,Commonly used inImprove production efficiency,Metal melting and casting,Energy conservation and environmental protection,Metal forging heating,Metal heat treatment and so on,is a Deep well isothermal quenching furnace,The price is more affordable。The following is to introduce the Deep well isothermal quenching furnace:

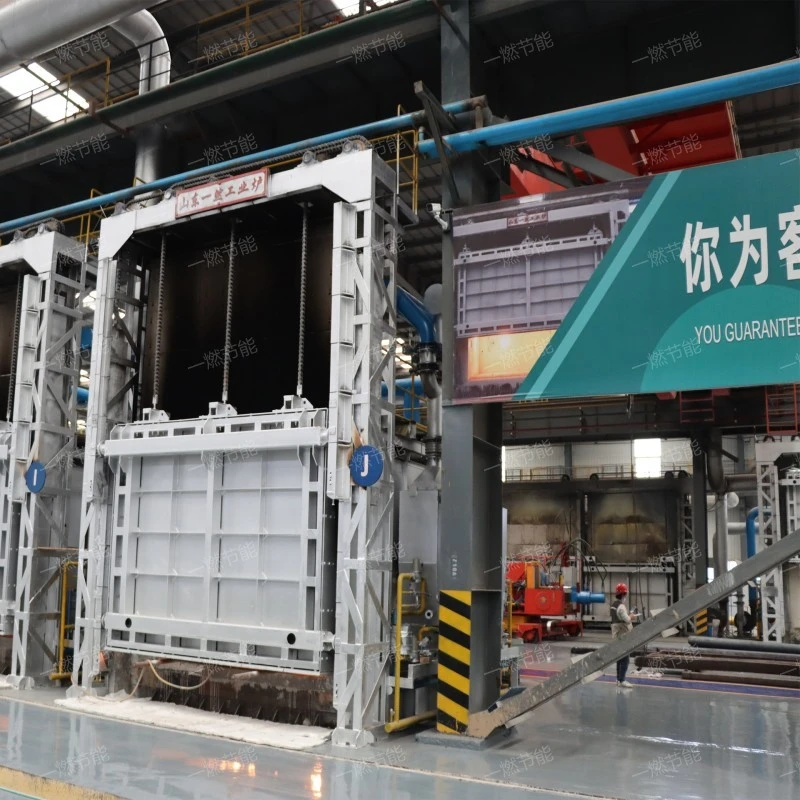

1、Brief introduction of Deep well isothermal quenching furnace

Deep well isothermal quenching furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.。

Deep well isothermal quenching furnace

2、Deep well isothermal quenching furnace function

Deep well isothermal quenching furnaceit has the functions of heat treatment, temper, normalizing, anneal and Forging heating,in the course of work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,be loved by our customers.。

Deep well isothermal quenching furnace

3、Deep well isothermal quenching furnace explanation video

Speak directly with facts on the spot。

Deep well isothermal quenching furnace

As you can see from the live video.,One-combustion energy saving it can be used in automobile, pharmacy, building materials, shipping, Machinery manufacturing and other industries。

4、Deep well isothermal quenching furnace structure composition

The Deep well isothermal quenching furnace has the following structure

- Radiation chamber

- furnace chamber

- convection chamber

- combustor

- Waste heat recovery system

The heat load of the main place for Deep well isothermal quenching furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

A space for holding metallic materials for heating.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Deep well isothermal quenching furnace

5、How much is the Deep well isothermal quenching furnace?

The Deep well isothermal quenching furnace price is introduced as follows:

- Brand strength

- Model specification

- raw material

- product quality

- Proper management mode

At present, there are various brands of Deep well isothermal quenching furnace in Shandong(Province). The performance, quality and after-sales of products under different brands are different, and the prices of Deep well isothermal quenching furnace are different.

The same type of equipment, with different models and sizes, has different investment costs, so the quotations to customers are naturally different. Generally speaking, the larger the model, the higher the price, and the smaller the model, the lower the price.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

The quality of the product determines the production process and results. Good quality means that the raw materials of the product are better and the price will definitely be higher.

One-combustion energy saving has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

Deep well isothermal quenching furnace

6、One-combustion energy saving after-sales service

On the premise of ensuring high quality and low price, One-combustion energy saving can also provide customers with high-standard services, help customers choose appropriate specifications and models, and install and debug products on site for them free of charge. If customers have special requirements, our company can also train product operators in operation knowledge. Besides, if everyone's products fail at any time, our company will rush to the scene to solve them in a short time and deal with them in time.。

One-combustion energy saving

Deep well isothermal quenching furnacemultifunctional, with functions such as quench, Casting heating, normalizing, heat treatment and anneal,the product looks beautiful.,the advantage is Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.、The use of clean and environmentally friendly natural gas as fuel effectively avoids the adverse effects of chemical reactions between impurities such as coal-fired furnaces and forgings during heating. At the same time, natural gas has high calorific value and high combustion temperature, and the combustion temperature can be further increased by preheating air and fuel. In addition, the gas forging heating furnace also has good heat loss control ability and intelligent control system, which can accurately adjust the ratio of air to natural gas, ensure full combustion of natural gas, and reduce mechanical incomplete combustion and chemical incomplete combustion.、Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.。

Related recommendation

-

What is a Stainless steel heating furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction and functional advantages of Side entry and side exit step heating furnace

2025-6-18 -

Introduction to Chain plate aluminum rod heating furnace and heating furnace structure principle

2025-5-27 -

Introduction to Fast heating quenching industrial furnace, Forging furnace specifications, model parameters

2025-5-27 -

What is a Large stainless steel annealing resistance heating furnace? Introduction to the Working Principle of Trolley resistance furnace

2025-5-27 -

Introduction to Deep well smelting furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Well type trolley forging furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

What is a Gas storage tubular roaster? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

What is a Rotary step heat treatment furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

What is a Multi functional trolley heating furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27