What is a Forging Heating Chamber Heating Furnace? Introduction to the Working Principle of Forging furnace

Forging Heating Chamber Heating FurnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,it has the functions of Forging heating, heat treatment, anneal, normalizing and Casting heating,the main features are Stable and reliable, Easy to control, Easy to control, energy-efficient and energy saving and environmental protection,is carefully developed by One-combustion energy saving combined with advanced technology。The following is to introduce the Forging Heating Chamber Heating Furnace:

1、Brief introduction of Forging Heating Chamber Heating Furnace

Forging Heating Chamber Heating FurnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,the product looks beautiful.,The overall structural design is relatively simple and compact.,it mainly includes Radiation chamber, ventilation system, combustor, convection chamber and recovery of waste heat,at runtime,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,usually used in war industry, electron, automobile, petroleum, material and other fields。

Forging Heating Chamber Heating Furnace

2、Video analysis of Forging Heating Chamber Heating Furnace

Speak directly with facts on the spot。

Forging Heating Chamber Heating Furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd the product looks beautiful.。

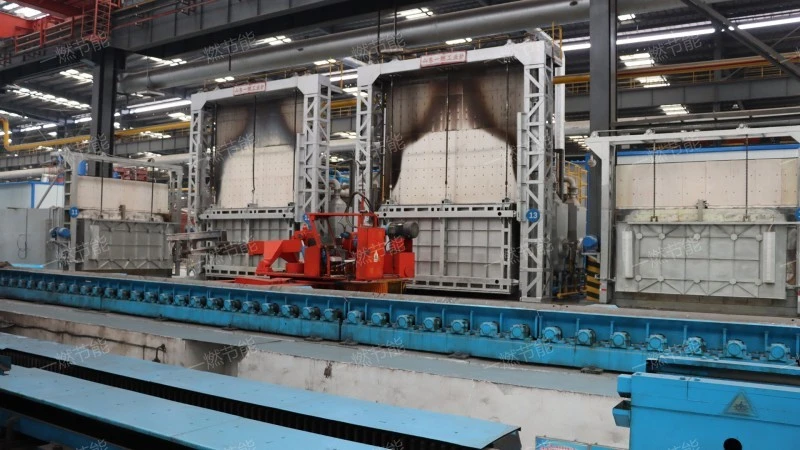

3、Forging Heating Chamber Heating Furnace HD real shot

High-definition pictures of reliable Forging Heating Chamber Heating Furnace at a glance。

Forging Heating Chamber Heating Furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Forging Heating Chamber Heating Furnace structure composition

The Forging Heating Chamber Heating Furnace has the following structure

- combustor

- furnace chamber

- Radiation chamber

- ventilation system

- combustor

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

A space for holding metallic materials for heating.

The heat load of the main place for Forging Heating Chamber Heating Furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Forging Heating Chamber Heating Furnace

5、Forging Heating Chamber Heating Furnace price advantage

The Forging Heating Chamber Heating Furnace price is introduced as follows:

- service

- Manufacturer scale

- product function

- technology

- quality

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Forging Heating Chamber Heating Furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Forging Heating Chamber Heating Furnace price can meet the purchasing needs of customers.

There are many Forging Heating Chamber Heating Furnace manufacturers on the market. Different manufacturers spend different costs, such as material costs, labor costs, manufacturing costs, etc., and their products are quoted differently.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

Quality is the fundamental factor that determines the price. The better the quality, the more detailed the manufacturing process, the more careful the materials are, the better the performance is, and the price will naturally be more expensive.

Forging Heating Chamber Heating Furnace

6、One-combustion energy saving delivery site

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Forging Heating Chamber Heating Furnacet operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Forging Heating Chamber Heating Furnace

As you can see from the live video.One-combustion energy saving structure mainly includes: combustor, ventilation system, furnace chamber, Radiation chamber, ventilation system and so on,Forging Heating Chamber Heating FurnaceThe overall structural design is simple and novel.。

Forging Heating Chamber Heating FurnaceThe high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,multifunctional, with functions such as hardening and tempering, temper, quench, Forging heating and temper,It is mostly used in Metal forging heating, Improve production efficiency, Metal tempering, Energy conservation and environmental protection, Metal tempering, Metal heat treatment and so on。

Related recommendation

-

Introduction to Double door quenching trolley forging furnace and forging furnace structure principle

2025-5-27 -

What is a Electric energy-saving industrial furnace? Trolley electric heating furnace specifications, models, and parameters

2025-5-27 -

What is a Adjustable resistance heating furnace? Introduction to the advantages and characteristics of the Trolley resistance furnace

2025-5-27 -

What is a Double door deep well furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

What is a Low temperature catalyst furnace external denitrification equipment? Introduction to the Working Principle of SCR denitration

2025-5-27 -

Introduction to Natural gas through heating furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

Introduction to Gas storage roller hearth furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Large scale walking furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Fully automatic natural gas trolley furnace and heating furnace working principle

2025-5-27 -

Introduction to Magnesium aluminum alloy heating furnace, introduction to heating furnace advantages and characteristics

2025-5-27