Introduction to Environmental protection material sealing pump, Material seal pump specifications, model parameters

Environmental protection material sealing pumpIt is a new type of pneumatic conveying equipment for powder, which uses the ejector effect of high-speed airflow to convey powder materials.,The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small and the use cost is reduced.、Using low-pressure conveying mode, the pressure of ash conveying medium is low, so the equipment pipes and valves are not easy to wear and prolong the service life.、By adopting the low positive pressure and fully sealed transportation mode, foreign substances can not enter the pipe and will not change the properties of the required materials.、Compared with the traditional mechanical conveying mode, the pneumatic conveying mode has higher energy efficiency ratio and lower energy consumption. The fully sealed design also reduces dust emission and is beneficial to environmental protection.、The low positive pressure and fully sealed conveying mode is adopted, which ensures that the powder will not leak to the external environment during the conveying process and meets the environmental protection requirements. The fully sealed design also prevents foreign substances from entering the tube, ensuring the purity and quality of the powder.,at work,Using high-speed airflow as power source, powder materials are transported from one place to another through the injection and carrying action of airflow.。The following is to introduce the Environmental protection material sealing pump:

1、Brief introduction of Environmental protection material sealing pump

Environmental protection material sealing pumpIt is a new type of pneumatic conveying equipment for powder, which belongs to the category of low-pressure dilute phase conveying, and mainly uses the ejector effect of high-speed airflow to convey powder materials.。

Environmental protection material sealing pump

2、Environmental protection material sealing pump function

Environmental protection material sealing pumpit has the functions of Conveying of powdery materials, Long-distance or complex terrain material transportation, Dust control, Raw material transportation and Waste disposal,It can be used for Waste disposal, Dust control, Raw material transportation, Waste disposal, Dust control, Conveying of powdery materials and so on。

Environmental protection material sealing pump

3、Environmental protection material sealing pump use

The purpose of Environmental protection material sealing pump is introduced as follows:

- Long-distance or complex terrain material transportation

- Supporting industrial production

- System integration and customization

- Powder material conveying

- Waste treatment and reuse

Environmental protection material sealing pumps are suitable for long-distance or complex terrain material transportation, such as mountains, hills, narrow urban spaces, etc., because they have the characteristics of Can be continuously conveyed..

In building materials such as commodity industry, Environmental protection material sealing pumps can be used to transport all kinds of raw materials and finished products to improve production efficiency.

The Environmental protection material sealing pump can also be used as a supporting equipment for large-scale pneumatic conveying system or powder treatment system, and work together with other equipment to realize automatic and continuous powder conveying.

The Environmental protection material sealing pump is mainly used for conveying all kinds of dry and loose powder materials, such as fly ash, alumina powder, dry kiln ash, limestone powder, cement powder and so on.

Environmental protection material sealing pumps can also be used in the field of waste treatment, such as conveying fly ash and other wastes for the production of environmentally friendly bricks or other recycling ways.

Environmental protection material sealing pump

4、Environmental protection material sealing pump characteristics

Environmental protection material sealing pumpfeatures include Small maintenance, Long service life, Convenient and flexible layout, Simple operation and omniseal,structure mainly includes: injector, sealing device, Bottom vaporization device, Bottom vaporization device, Supporting and connecting parts and so on,Environmental protection material sealing pumpThe overall structural design is relatively simple。

Environmental protection material sealing pump

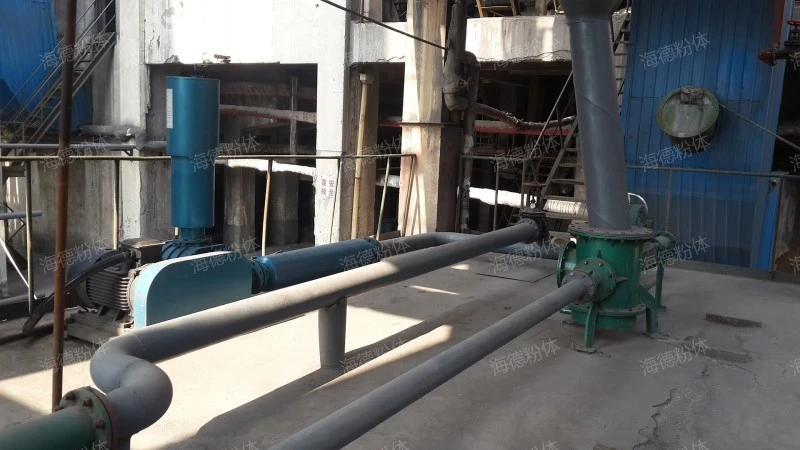

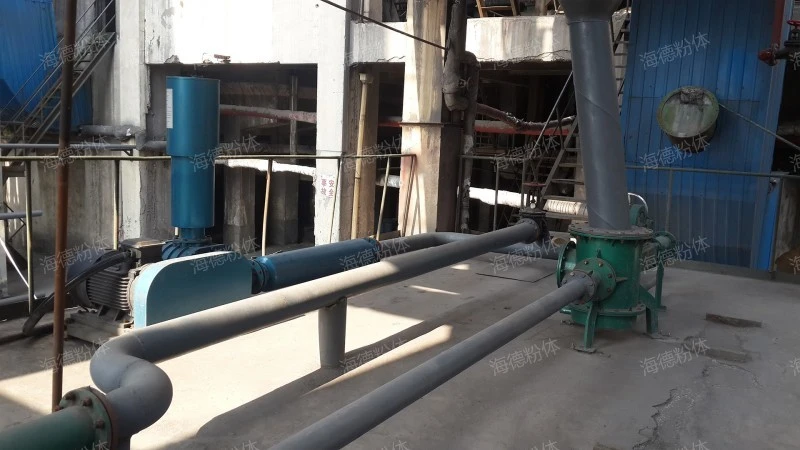

5、Environmental protection material sealing pump HD real shot

hyde powder provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Environmental protection material sealing pumpt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Environmental protection material sealing pump

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. multifunctional, with functions such as Dust control, Long-distance or complex terrain material transportation, System supporting use, Conveying of powdery materials and Dust control。

6、hyde powder introduced

hyde, as one of the professional and powerful Environmental protection material sealing pump manufacturers in jinan, produces Environmental protection material sealing pump with reliable quality, affordable price and perfect after-sales, which have been successfully practiced in many processing plants at home and abroad.。

hyde powder

Environmental protection material sealing pumpis a Environmental protection material sealing pump,Based on the ejector effect of high-speed airflow, the mixing and acceleration of airflow and powder, the formation of material column and pressure balance, the isolation and sealing of positive and negative pressure, and the automatic adjustment and adaptation.。

Related recommendation

-

Introduction to Calcium oxide pneumatic conveying, how much is the price of the pneumatic conveying?

2025-5-26 -

Introduction to Combustible gas conveying Roots blower and Three leaf Roots blower structure principle

2025-5-26 -

Introduction to Metallurgical coke powder pneumatic conveying, Material conveying advantages, characteristics and principles

2025-5-26 -

Introduction to Leak proof feeder, advantages, characteristics and principles of Feeder

2025-5-26 -

What is a Foam plastic conveying? Introduction to the advantages, characteristics, and principles of the pneumatic conveying

2025-5-26 -

Introduction to Fully mechanical sealed Roots vacuum pump equipment, how much is the price of the blower?

2025-5-26 -

Introduction to Automatic measuring, weighing and conveying equipment and Pneumatic conveying equipment structure principle

2025-5-26 -

Introduction to Heavy powder conveying equipment and Material conveying advantages and features

2025-5-26 -

What is a Water bag powder conveying? Introduction to the advantages and characteristics of the Pneumatic conveying equipment

2025-5-26 -

What is a Combustible gas booster Roots blower? How much is the price of the Three leaf Roots blower?

2025-5-26