Introduction to Automatic loading and unloading heat treatment industrial furnace and Forging furnace working principle

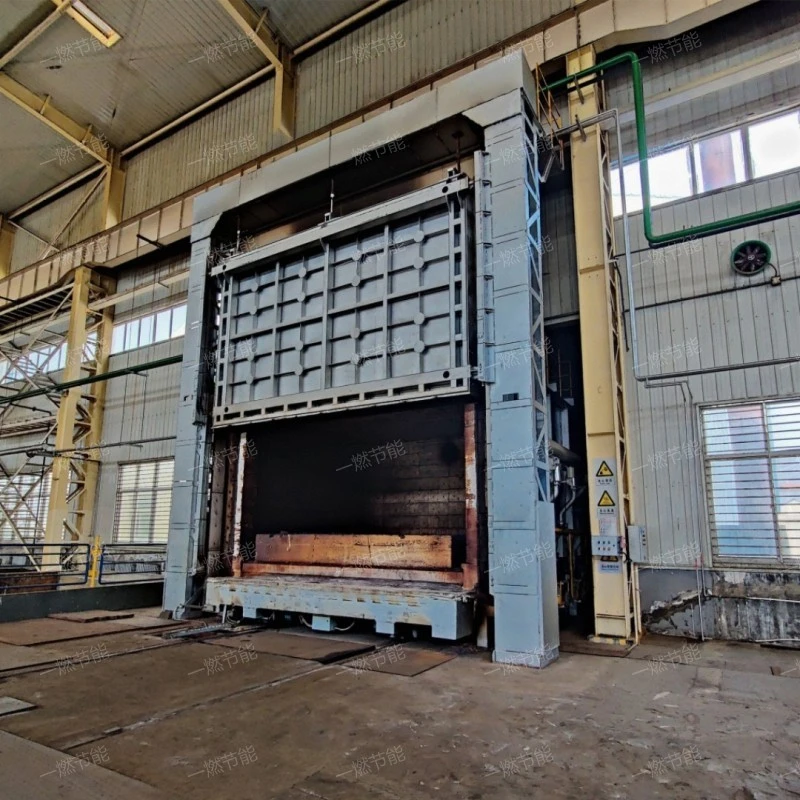

Automatic loading and unloading heat treatment industrial furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,it is an ideal choice for customers to buy Automatic loading and unloading heat treatment industrial furnace。

1、Brief introduction of Automatic loading and unloading heat treatment industrial furnace

Automatic loading and unloading heat treatment industrial furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.。

Automatic loading and unloading heat treatment industrial furnace

2、Automatic loading and unloading heat treatment industrial furnace application

Automatic loading and unloading heat treatment industrial furnaces have the following purposes.

- Improve production efficiency

- Metal heat treatment

- Metal tempering

- Metal melting and casting

- Metal forging heating

The Automatic loading and unloading heat treatment industrial furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

In addition to forging heating, Automatic loading and unloading heat treatment industrial furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the Automatic loading and unloading heat treatment industrial furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

Although it is mainly used for forging heating, some types of Automatic loading and unloading heat treatment industrial furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The Automatic loading and unloading heat treatment industrial furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Automatic loading and unloading heat treatment industrial furnace

3、Automatic loading and unloading heat treatment industrial furnace video

On-site aerial photography of Automatic loading and unloading heat treatment industrial furnace。

Automatic loading and unloading heat treatment industrial furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd the product looks atmospheric.。

4、Automatic loading and unloading heat treatment industrial furnace principle

Automatic loading and unloading heat treatment industrial furnacethe principle is simple.The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,usually used in material, electron, chemical industry, war industry, Machinery manufacturing and other fields,It has a wide range of uses, and is often used inImprove production efficiency,Metal forging heating,Metal melting and casting,Metal tempering,Metal melting and casting and so on,the product looks beautiful.,is an advanced Automatic loading and unloading heat treatment industrial furnace developed by our company in combination with the actual situation of the industry。

Automatic loading and unloading heat treatment industrial furnace

5、Automatic loading and unloading heat treatment industrial furnace explanation video

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Automatic loading and unloading heat treatment industrial furnace

As you can see from the live video.,One-combustion energy saving multifunctional, with functions such as anneal, Forging heating, anneal, Casting heating and temper。

Automatic loading and unloading heat treatment industrial furnaceis a Automatic loading and unloading heat treatment industrial furnace,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.。

Related recommendation

-

Introduction to Normalizing trolley forging heating furnace, Forging furnace specifications, model parameters

2025-5-27 -

Introduction to SCR catalytic reduction denitrification system, introduction to SCR denitration system function advantages and characteristics

2025-5-27 -

Introduction to Low temperature SCR denitration system, SCR denitration system advantages, characteristics and principles

2025-5-27 -

Introduction to Multi functional steel rolling heating furnace, Forging furnace specifications, model parameters

2025-5-27 -

Introduction to Aluminum alloy industrial resistance heating furnace, introduction to Trolley resistance heating furnace advantages and characteristics

2025-5-27 -

What is a Dual car carbonization furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to SCR low-temperature catalytic absorption flue gas denitrification and SCR flue gas denitrification structure principle

2025-5-27 -

Introduction to Bright quenching heat treatment furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Dual car resistance heating furnace and Trolley resistance heating furnace structure principle

2025-5-27 -

Introduction to Industrial gas trolley furnace, forging furnace advantages, characteristics and principles

2025-5-27