What is a Automatic top cylinder forging heating furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

Automatic top cylinder forging heating furnaceIt is a forging heating device using gas as fuel.。

1、Brief introduction of Automatic top cylinder forging heating furnace

Automatic top cylinder forging heating furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,Widely used inMetal tempering,Improve production efficiency,Energy conservation and environmental protection,Metal melting and casting,Improve production efficiency and so on,has been favored by more and more customers.。

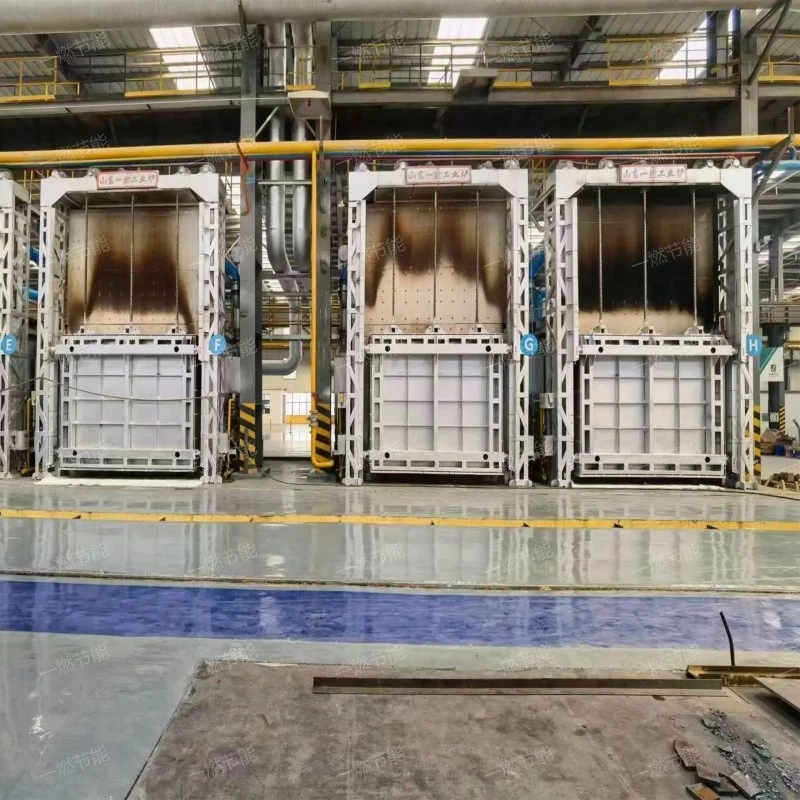

Automatic top cylinder forging heating furnace

2、Automatic top cylinder forging heating furnace characteristics

The Automatic top cylinder forging heating furnace features are as follows:

- Easy to control

- Strong adaptability

- Efficient heating

- energy saving and environmental protection

- Easy to maintain

The combustion system and ventilation system of the Automatic top cylinder forging heating furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Automatic top cylinder forging heating furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The Automatic top cylinder forging heating furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

As a clean energy source, natural gas produces less pollutants after combustion, which is beneficial to environmental protection. At the same time, the application of waste heat recovery system further improves the energy utilization efficiency.

The structural design of the Automatic top cylinder forging heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

Automatic top cylinder forging heating furnace

3、Automatic top cylinder forging heating furnace explanation video

Speak directly with facts on the spot。

Automatic top cylinder forging heating furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd Easy to control,energy saving and environmental protection,Easy to maintain,energy-efficient,energy saving and environmental protection。

4、Advantages of Automatic top cylinder forging heating furnace principle

Automatic top cylinder forging heating furnacein the course of work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,is a kind of high quality and low price Automatic top cylinder forging heating furnace。

Automatic top cylinder forging heating furnace

5、Automatic top cylinder forging heating furnace advantage

The advantages of Automatic top cylinder forging heating furnace are as follows:

- Rapid temperature rise

- Reduce operating costs

- Extend the service life of equipment

- Reduce operating costs

- Uniform heating

The Automatic top cylinder forging heating furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

The efficient combustion and waste heat recovery system of the Automatic top cylinder forging heating furnace can significantly reduce energy consumption, thus reducing operating costs.

The Automatic top cylinder forging heating furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The efficient combustion and waste heat recovery system of the Automatic top cylinder forging heating furnace can significantly reduce energy consumption, thus reducing operating costs.

The Automatic top cylinder forging heating furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

Automatic top cylinder forging heating furnace

6、Automatic top cylinder forging heating furnace price

The Automatic top cylinder forging heating furnace price is introduced as follows:

- geographical position

- product function

- technology

- model

- Configuration difference

One-combustion energy savingJinan, the transportation is convenient, and the corresponding cost of transporting Automatic top cylinder forging heating furnace is low, which reduces the cost of selling Automatic top cylinder forging heating furnace by manufacturers, and the price will also decrease.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

One-combustion energy saving is a professional Production and processing center, the Automatic top cylinder forging heating furnace of various specifications and models manufactured are affordable, reliable in quality, good in performance and perfect after-sales, which is a good choice for everyone to buy Automatic top cylinder forging heating furnace.

If the comprehensive configuration of the product is higher, the selling price of the product will be higher, otherwise the price will be lower, so there is a close relationship between the configuration level and the price.

Automatic top cylinder forging heating furnace

Automatic top cylinder forging heating furnaceis a Automatic top cylinder forging heating furnace,it has the functions of normalizing, anneal, temper, quench and hardening and tempering。

Related recommendation

-

Introduction to Magnesium aluminum alloy heating furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Heat treatment tube annealing furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Tubular heat treatment furnace and Forging furnace working principle

2025-5-27 -

Introduction to High temperature bright annealing furnace and Forging furnace advantages and features

2025-5-27 -

What is a Pit type roasting furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

Introduction to Stage type shell baking furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

What is a Medium temperature trolley resistance furnace? Introduction to the Working Principle of Trolley resistance furnace

2025-5-27 -

Introduction to Large chamber furnace and Forging furnace advantages and features

2025-5-27 -

What is a Through type forging furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Energy saving box type resistance heating furnace? Introduction to the Working Principle of Trolley resistance furnace

2025-5-27