Introduction to Electric heating continuous annealing furnace and Trolley resistance heating furnace working principle

Electric heating continuous annealing furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,the product looks beautiful.,is developed and improved by One-combustion energy saving。The following is to introduce the Electric heating continuous annealing furnace:

1、Brief introduction of Electric heating continuous annealing furnace

Electric heating continuous annealing furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,It has a wide range of uses, including normalizing, Powder metallurgy sintering, Melting of low melting point metal, anneal and quench,Simple structure and reliable operation.,the main structure includes fire door, furnace shell, Temperature control system, furnace chamber, heating element and so on,is a kind of high quality and low price Electric heating continuous annealing furnace,the main features are Easy to control, Accurate temperature control, Low maintenance cost, Strong adaptability and Environmental protection and safety。

Electric heating continuous annealing furnace

2、Working principle of Electric heating continuous annealing furnace

Electric heating continuous annealing furnaceat work,Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.,It has a wide range of uses, and is often used inhardening and tempering,Roasting and annealing of glass ceramics,Heating before metal forging,anneal,Powder metallurgy sintering and so on,it has the characteristics of High flexibility, Environmental protection and energy saving, High thermal efficiency, Easy to operate and maintain. and Long service life,support customization。

Electric heating continuous annealing furnace

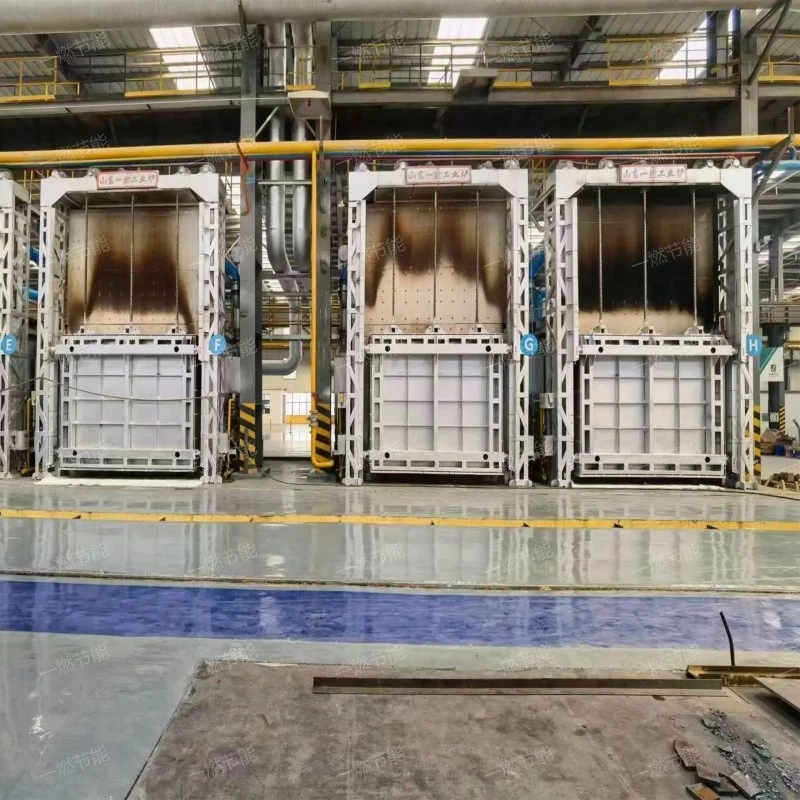

3、Physical picture of Electric heating continuous annealing furnace

Electric heating continuous annealing furnace manufacturer, the product High definition real shot. In order to facilitate new and old customers to find satisfactory the product looks atmospheric. more quickly, the following high-definition pictures are provided for reference.。

Electric heating continuous annealing furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Electric heating continuous annealing furnace function

Electric heating continuous annealing furnaceit has the functions of Casting heating, temper, heat treatment, normalizing and Forging heating。

Electric heating continuous annealing furnace

5、Electric heating continuous annealing furnace structure

The Electric heating continuous annealing furnace structure is introduced as follows:

- Temperature control system

- eye split

- base

- heating element

- fire door

The temperature control system is used to accurately control the temperature in the furnace to meet different process requirements.

It is arranged on the furnace body and used to observe the heating situation in the furnace.

Used to support the whole Electric heating continuous annealing furnace and ensure its stability.

The heating element is the core component of the Electric heating continuous annealing furnace, which is responsible for converting electric energy into heat energy. Common heating elements include resistance wires, resistance bands and electric heating tubes. According to the temperature requirement and heating speed in the furnace, different types of heating elements can be selected.

The furnace Electric heating continuous annealing furnace is the passage for operators to enter and leave the furnace, and it also plays a certain sealing role. It can effectively prevent the heat in the furnace from leaking out and the cold air from outside from entering, and ensure the stability of the temperature in the furnace.

Electric heating continuous annealing furnace

6、company profile

One-combustion energy saving is a strong and professional Electric heating continuous annealing furnace manufacturer, with advanced Electric heating continuous annealing furnace production technology and rich production experience. It will not only provide users with Electric heating continuous annealing furnace with Fast heating speed, but also provide users with complete pre-sales, in-sales and after-sales services for the benefit of users. Welcome new and old users to visit and buy.。

One-combustion energy saving

Electric heating continuous annealing furnaceit is mainly composed of furnace shell, fire door, thermal insulation (material), Temperature control system and heating element,Electric heating continuous annealing furnaceThe overall structural design is relatively simple and compact.,Easy to control, accurate temperature control, and easy to realize automatic control.、Fast heating, the Electric heating continuous annealing furnace can quickly raise the temperature to the set temperature, shorten the heating time and improve the production efficiency. In particular, the heating Electric heating continuous annealing furnace is directly heated, and the current directly passes through the material, so the heating speed is faster.、Environmental protection, energy saving, no pollutants generated by fuel combustion, in line with environmental protection requirements; At the same time, due to high thermal efficiency, energy consumption is relatively low.、The safety is high, and the Electric heating continuous annealing furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.、Strong customization, the Electric heating continuous annealing furnace can be customized according to the actual needs of users, such as heating power, furnace size, temperature control accuracy, etc., to meet the requirements of specific processes.,is a popular Electric heating continuous annealing furnace。

Related recommendation

-

Introduction to End in end out stepper furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

What is a Circular deep well furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Heat treatment tube annealing furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Gas storage chamber furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Trolley ring heating furnace and heating furnace advantages and features

2025-5-27 -

What is a Aluminum mold heating furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Plate heating furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

Introduction to Tubular heat treatment furnace and Forging furnace working principle

2025-5-27 -

What is a Continuous natural gas trolley furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to High temperature forging furnace, Forging furnace advantages, characteristics and principles

2025-5-27