Brief introduction and functional advantages of Casting heating furnace

Casting heating furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,is a Casting heating furnace。The following is to introduce the Casting heating furnace:

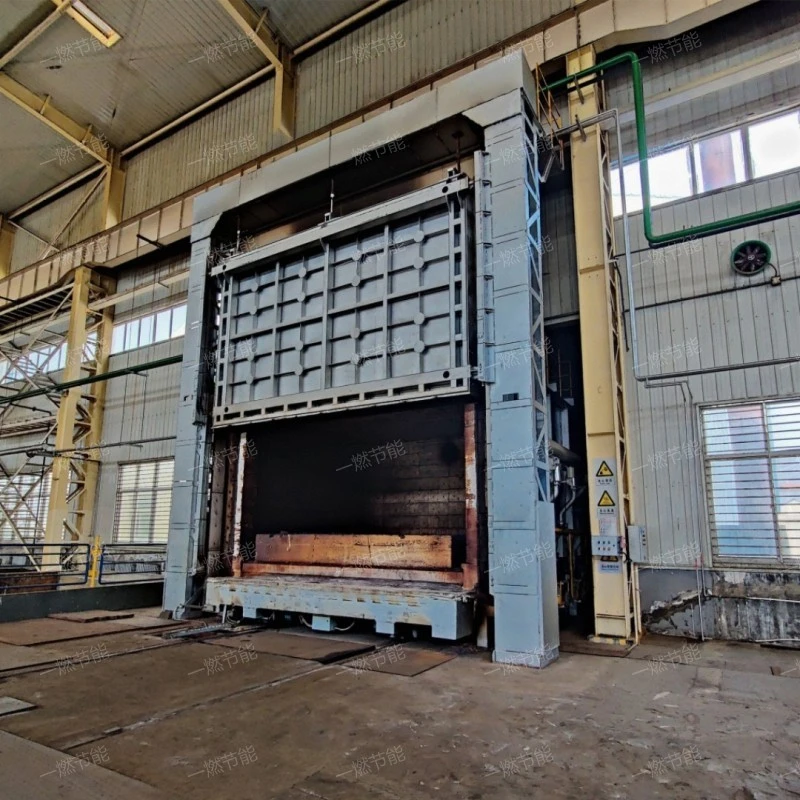

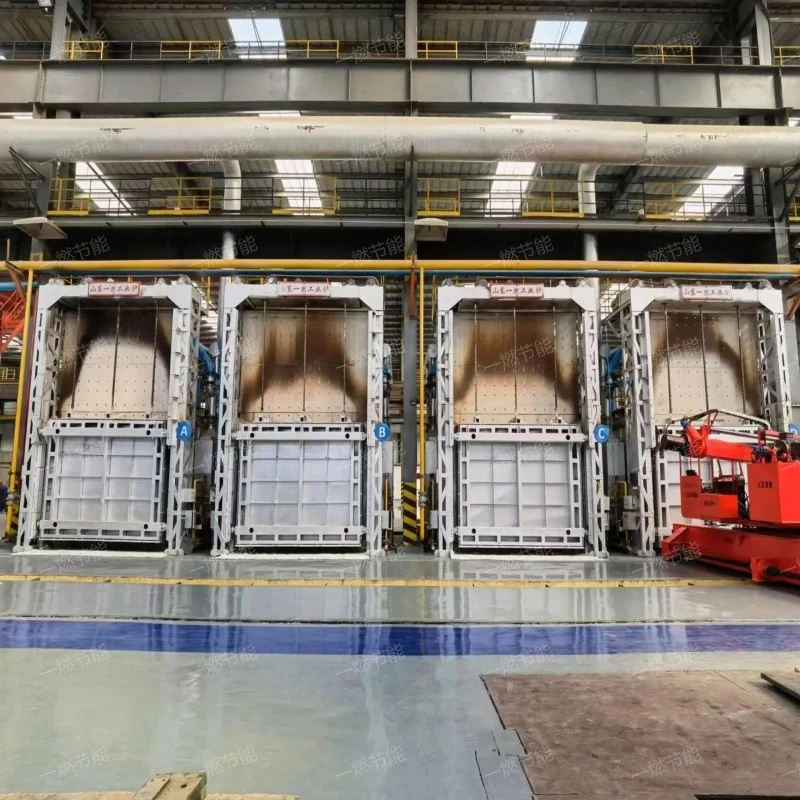

1、Brief introduction of Casting heating furnace

Casting heating furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,it is widely used in Machinery manufacturing, metallurgy, Household necessities, building materials and chemical industry,The overall structural design is simple, diverse and beautiful.,the main structure includes ventilation system, convection chamber, furnace chamber, furnace chamber, ventilation system and so on,at the start of the operation,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,is a kind of high quality and low price Casting heating furnace。

Casting heating furnace

2、Structural characteristics of Casting heating furnace

The Casting heating furnace has the following structure

- ventilation system

- furnace chamber

- combustor

- convection chamber

- ventilation system

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

A space for holding metallic materials for heating.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Casting heating furnace

3、Working principle of Casting heating furnace

Casting heating furnacethe principle is simple.Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.。

Casting heating furnace

4、Casting heating furnace use

The purpose of Casting heating furnace is introduced as follows:

- Metal forging heating

- Metal melting and casting

- Energy conservation and environmental protection

- Energy conservation and environmental protection

- Improve production efficiency

The Casting heating furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Although it is mainly used for forging heating, some types of Casting heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The Casting heating furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

The Casting heating furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

The Casting heating furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

Casting heating furnace

5、Casting heating furnace function

Casting heating furnaceit has the functions of Forging heating, normalizing, Casting heating, heat treatment and Forging heating,is a popular Casting heating furnace。

Casting heating furnace

6、Casting heating furnace price

The Casting heating furnace price is introduced as follows:

- Cost input

- product function

- product function

- product quality

- service

The cost of manufacturing Casting heating furnace varies from manufacturer to manufacturer. The higher the cost of manufacturing products, the higher the product price will be. On the other hand, the lower the production cost, the lower the product price, but the quality of products with high production cost is guaranteed, which can reduce the maintenance cost of customers.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Generally speaking, the higher the product quality, the higher the Casting heating furnace price. A reasonable balance is made between quality and price, so that the comprehensive quality of the product can meet the customer's use standards and meet the basic needs of customers in terms of price.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Casting heating furnace price and service can meet the actual needs of customers.

Casting heating furnace

Casting heating furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,is a common Casting heating furnace,in the course of work,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.。

Related recommendation

-

Introduction to Full fiber high-temperature trolley forging furnace and forging furnace working principle

2025-5-27 -

Introduction to Quenching heat treatment heating furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

台车式热处理炉

2023-06-12 -

What is a Double ended trolley electric heating furnace? Introduction to the advantages, characteristics, and principles of the Trolley electric heating furnace

2025-5-27 -

What is a Large roller hearth furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

What is a Split type trolley furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Continuous natural gas trolley furnace and heating furnace working principle

2025-5-27 -

Introduction to Natural gas truck furnace and heating furnace working principle

2025-5-27 -

Introduction to Protective gas trolley furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

What is a Regenerative burner tube annealing furnace? Introduction to the Working Principle of forging furnace

2025-5-27