Introduction to Denitrification equipment for forging heating furnace and SCR denitration structure principle

Denitrification equipment for forging heating furnacethat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,it can be used in metallurgy, Gas power plant, cement plant, iron and steel plant, building materials and other industries,it is an ideal choice for customers to buy Denitrification equipment for forging heating furnace。The following is to introduce the Denitrification equipment for forging heating furnace:

1、Brief introduction of Denitrification equipment for forging heating furnace

Denitrification equipment for forging heating furnaceis an efficient, stable and environment-friendly flue gas denitrification technology.,at work,Ammonia gas or other suitable reducing agent (such as urea aqueous solution) is sprayed into the flue gas upstream of the catalyst at high temperature. Under the action of catalyst, the reducing agent selectively reacts with nitrogen oxides (NOx) in flue gas to generate pollution-free nitrogen and water vapor. Because NH3 is selective, it only reacts with NOx and basically does not react with O2, so this technology is called selective catalytic reduction denitrification.,it has the functions of environmental protection, Improve working conditions, environmental protection, Improve energy efficiency and Improve working conditions。

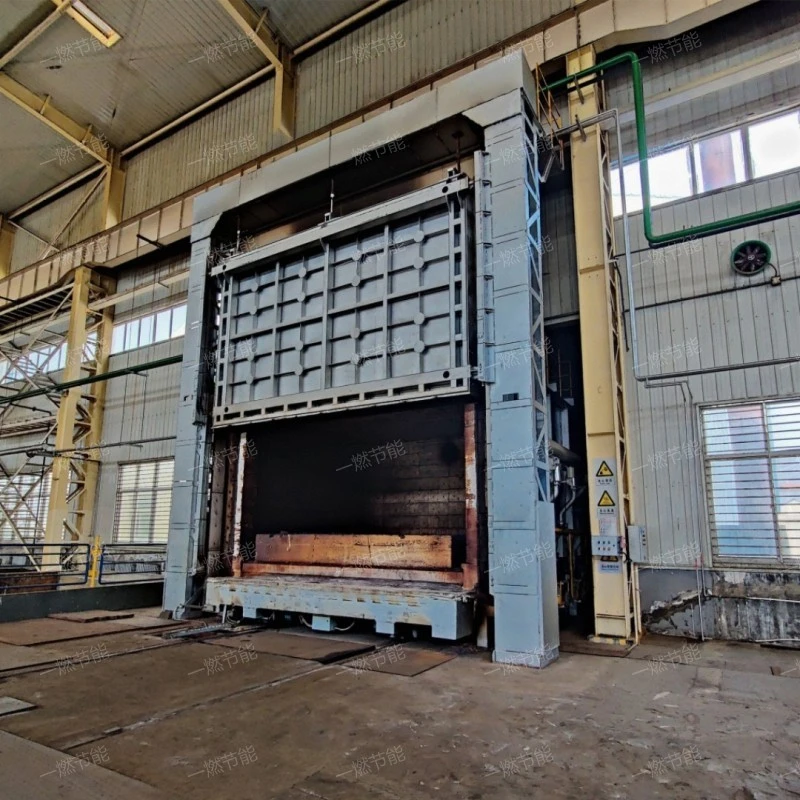

Denitrification equipment for forging heating furnace

2、Structural advantages of Denitrification equipment for forging heating furnace

The Denitrification equipment for forging heating furnace has the following structure

- Flue gas mixing and distribution system

- Catalytic reduction reaction

- Reducing agent storage and supply system

- Reactor

- Reducing agent supply

Ensure that the flue gas and reducing agent are fully mixed in the reactor to improve the denitrification efficiency.

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

It is the core component of Denitrification equipment for forging heating furnace technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

Reducing agents such as liquid pure ammonia or ammonia water (aqueous solution of ammonia) are evaporated and mixed with diluted air or flue gas.

Denitrification equipment for forging heating furnace

3、Denitrification equipment for forging heating furnace video

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Denitrification equipment for forging heating furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd it has the functions of Promote sustainable development, Improve working conditions, Improve energy efficiency, Promote sustainable development and environmental protection。

4、Denitrification equipment for forging heating furnace function

Denitrification equipment for forging heating furnacemultifunctional, with functions such as Improve working conditions, environmental protection, Promote sustainable development, Improve energy efficiency and Improve working conditions,it has been widely used in Gas power plant, iron and steel plant, building materials, cement plant, metallurgy and other industries。

Denitrification equipment for forging heating furnace

5、How much is the Denitrification equipment for forging heating furnace?

The Denitrification equipment for forging heating furnace price is introduced as follows:

- product configuration

- geographical position

- Brand strength

- raw material

- Parameter size

The difference in Denitrification equipment for forging heating furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

One-combustion energy savingShandong(Province), the transportation is convenient, and the corresponding cost of transporting Denitrification equipment for forging heating furnace is low, which reduces the cost of selling Denitrification equipment for forging heating furnace by manufacturers, and the price will also decrease.

At present, there are various brands of Denitrification equipment for forging heating furnace in Jinan, Shandong province. The performance, quality and after-sales of products under different brands are different, and the prices of Denitrification equipment for forging heating furnace are different.

The quality of material selection is one of the main factors that directly affect the Denitrification equipment for forging heating furnace. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

The same type of equipment, with different models and sizes, has different investment costs, so the quotations to customers are naturally different. Generally speaking, the larger the model, the higher the price, and the smaller the model, the lower the price.

Denitrification equipment for forging heating furnace

6、One-combustion energy saving's after-sales service

Our company will not only provide customers with excellent quality Denitrification equipment for forging heating furnace, but also choose a series of high-quality services such as appropriate specifications and models according to their actual needs.。

One-combustion energy saving

Denitrification equipment for forging heating furnacethe principle is simple.Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,Commonly used inMeet the requirements of environmental protection,environmental protection,Promote sustainable development,Improve product quality,Flue gas denitrification and so on,is a kind of high quality and low price Denitrification equipment for forging heating furnace。

Related recommendation

-

Introduction to Regenerative gas through furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Stepping forging furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Multi functional roller furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Denitrification of forging furnace and SCR denitration structure principle

2025-5-27 -

What is a Continuous roller heating furnace? How much is the price of the heating furnace?

2025-5-27 -

What is a Steel plant ring furnace denitrification equipment? Introduction to the Working Principle of SCR denitration

2025-5-27 -

Introduction to Tempering heat treatment electric furnace and Trolley electric heating furnace advantages and features

2025-5-27 -

台车工业调质炉

2023-06-06 -

热处理炉

2023-03-23 -

What is a Gas storage walking back and forth furnace? How much is the price of the Forging furnace?

2025-5-27