Introduction to Denitrification equipment for forging industrial furnaces, advantages, characteristics and principles of SCR denitration

Denitrification equipment for forging industrial furnacesis an efficient, stable and environment-friendly flue gas denitrification technology.,it has the characteristics of Strong adaptability, Stable operation, Mature technology, Promote sustainable development and High denitration efficiency,it has the functions of environmental protection, Promote sustainable development, Improve energy efficiency, environmental protection and Improve working conditions,the product looks beautiful.,it is an ideal choice for customers to buy Denitrification equipment for forging industrial furnaces。The following is to introduce the Denitrification equipment for forging industrial furnaces:

1、Brief introduction of Denitrification equipment for forging industrial furnaces

Denitrification equipment for forging industrial furnacesthe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,widely used in Gas power plant, coal-fired power station, iron and steel plant, cement plant, Gas power plant and other fields,it has the functions of Promote sustainable development, environmental protection, Improve energy efficiency, Improve working conditions and Promote sustainable development。

Denitrification equipment for forging industrial furnaces

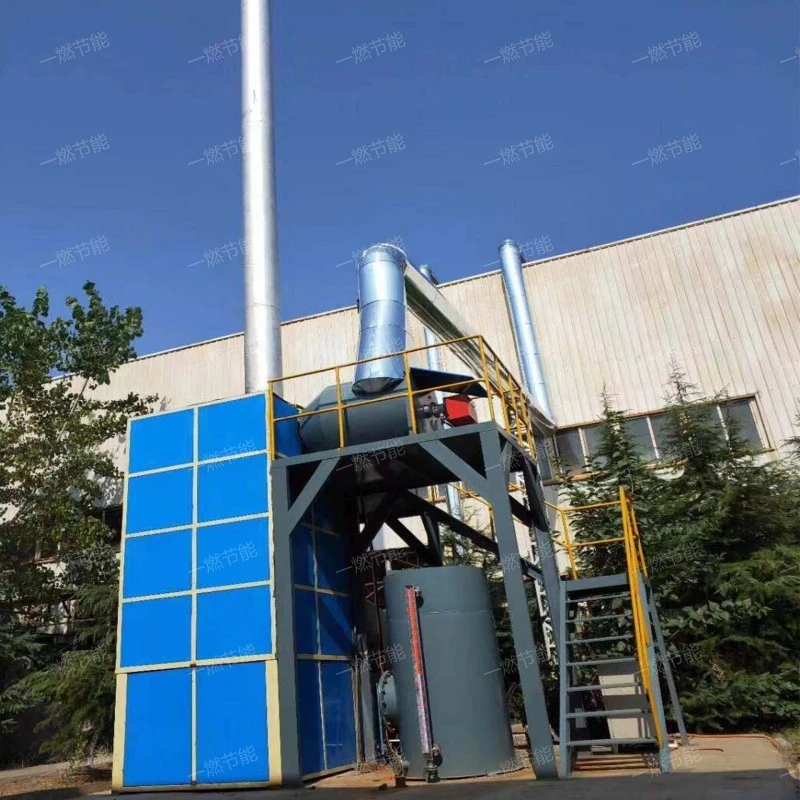

2、Denitrification equipment for forging industrial furnaces HD real shot

On-site aerial photography of Denitrification equipment for forging industrial furnaces。

Denitrification equipment for forging industrial furnaces

As you can see from the live video.,One-combustion energy saving the main features are Efficient denitration, Stable operation, Mature and stable technology, Environment friendly and Strong adaptability。

3、Denitrification equipment for forging industrial furnaces HD picture real shot

Overview of high-definition pictures,the product looks atmospheric.。

Denitrification equipment for forging industrial furnaces

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Denitrification equipment for forging industrial furnaces principle

Denitrification equipment for forging industrial furnacesUnder the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,is an efficient, stable and environment-friendly flue gas denitrification technology.。

Denitrification equipment for forging industrial furnaces

5、Denitrification equipment for forging industrial furnaces use

Denitrification equipment for forging industrial furnacesIt has a wide range of uses, and is often used inMeet the requirements of environmental protection,Promote sustainable development,Improve product quality,Meet the requirements of environmental protection,Improve product quality and so on,can be customized according to user's needs.。

Denitrification equipment for forging industrial furnaces

6、Denitrification equipment for forging industrial furnaces price consultation

The Denitrification equipment for forging industrial furnaces price is introduced as follows:

- After-sales service level

- Configuration difference

- Reasonable sales model

- Product technology

- cost of production

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Denitrification equipment for forging industrial furnaces price and service can meet the actual needs of customers.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Denitrification equipment for forging industrial furnaces are closely related. One-combustion energy saving has comprehensively measured the configuration and sales price of products when designing Denitrification equipment for forging industrial furnaces, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the Denitrification equipment for forging industrial furnaces just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

Denitrification equipment for forging industrial furnaces

Denitrification equipment for forging industrial furnacesit is widely used incoal-fired power station,building materials,metallurgy,iron and steel plant,metallurgy and other industries,that is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,multifunctional, with functions such as Improve working conditions, environmental protection, Improve energy efficiency, Promote sustainable development and Improve energy efficiency。

Related recommendation

-

Introduction to Continuous roller quenching heat treatment furnace and forging furnace working principle

2025-5-27 -

Introduction to High temperature and low dust SCR flue gas denitrification, SCR flue gas denitrification specifications, model parameters

2025-5-27 -

Introduction to Energy saving box type electric furnace, introduction to Trolley electric heating furnace function advantages and characteristics

2025-5-27 -

What is a Chain plate quenching heat treatment furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

Introduction to SCR low-temperature denitrification equipment, how much is the price of the SCR flue gas denitrification?

2025-5-27 -

Introduction to Isothermal annealing furnace and forging furnace working principle

2025-5-27 -

Brief introduction and advantages of High manganese steel trolley heating furnace

2025-6-18 -

What is a Burner heating furnace chamber type? Introduction to the principle of heating furnace structure

2025-5-27 -

What is a Seamless steel pipe heating furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Industrial natural gas trolley furnace and heating furnace working principle

2025-5-27