What is a Denitrification of forging industrial furnace? Introduction to the advantages and characteristics of the SCR denitration system

Denitrification of forging industrial furnacethe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,is an advanced Denitrification of forging industrial furnace developed by our company in combination with the actual situation of the industry。The following is to introduce the Denitrification of forging industrial furnace:

1、Brief introduction of Denitrification of forging industrial furnace

Denitrification of forging industrial furnaceit refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.,it can be used in metallurgy, coal-fired power station, cement plant, Gas power plant, iron and steel plant and other industries,modern technology。

Denitrification of forging industrial furnace

2、Denitrification of forging industrial furnace structure composition

The Denitrification of forging industrial furnace has the following structure

- Reducing agent storage and supply system

- control system

- Flue gas mixing and distribution

- Flue gas mixing and distribution

- Reactor

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

The whole Denitrification of forging industrial furnace is automatically controlled, including the adjustment of reducing agent supply, flue gas flow and temperature, so as to ensure the stable operation of the system and achieve the expected denitrification effect.

The mixed reducing agent and flue gas are fully mixed in the mixing tube and evenly distributed to the catalyst reactor through the distribution system.

The mixed reducing agent and flue gas are fully mixed in the mixing tube and evenly distributed to the catalyst reactor through the distribution system.

It is the core component of Denitrification of forging industrial furnace technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

Denitrification of forging industrial furnace

3、Denitrification of forging industrial furnace video

You can buy Denitrification of forging industrial furnace according to your needs and show you product videos.。

Denitrification of forging industrial furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd multifunctional, with functions such as Improve working conditions, Improve working conditions, Promote sustainable development, Improve energy efficiency and environmental protection。

4、Denitrification of forging industrial furnace function

Denitrification of forging industrial furnacemultifunctional, with functions such as Improve working conditions, environmental protection, Improve energy efficiency, environmental protection and Promote sustainable development,support customization。

Denitrification of forging industrial furnace

5、Denitrification of forging industrial furnace price

The Denitrification of forging industrial furnace price is introduced as follows:

- region

- market

- product quality

- Manufacturer's strength

- product function

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

In order to build their own brands, some manufacturers deliberately reduce the price of Denitrification of forging industrial furnace. The price of competitors will affect the pricing of equipment more or less, and the price may be lower.

The selling price of excellent quality products is also high, so users should also consider the quality and price of products comprehensively when purchasing products, so as to buy products with high cost performance.

Reliable manufacturers can produce excellent products, and such manufacturers have high comprehensive credibility and can design products in all directions. Therefore, compared with other manufacturers, such products have higher scientific and technological content and more functions. One-combustion energy saving's reputation and products are very high, and it is a trustworthy big brand and manufacturer.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Denitrification of forging industrial furnace

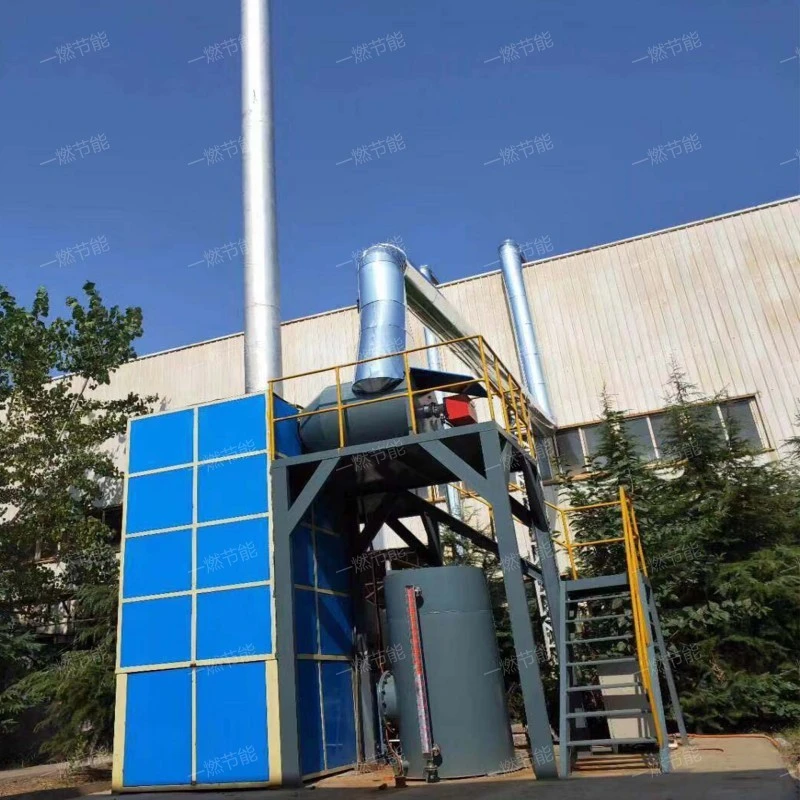

6、Real-time shooting in One-combustion energy saving's production workshop

The finished products of the Denitrification of forging industrial furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Denitrification of forging industrial furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Denitrification of forging industrial furnaceit has the functions of Improve energy efficiency, Improve working conditions, environmental protection, Improve energy efficiency and Promote sustainable development,Strong adaptability,Promote sustainable development,Stable operation,energy saving and environmental protection,Efficient denitration,it has been widely used in metallurgy, coal-fired power station, Gas power plant, iron and steel plant, cement plant and other industries。

Related recommendation

-

What is a Denitrification equipment for forging industry? Introduction to the principle of SCR flue gas denitrification structure

2025-5-27 -

Introduction to Double car roasting furnace, how much is the price of the heating furnace?

2025-5-27 -

What is a Car preheating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Forging heating trolley forging furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

Introduction to Split type heat treatment furnace and heating furnace advantages and features

2025-5-27 -

Introduction to Pit type forging furnace and Forging furnace advantages and features

2025-5-27 -

What is a Denitrification of steel plant heating furnace? Introduction to the advantages and characteristics of SCR denitration system functions

2025-5-27 -

Introduction to Open close heat treatment furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Full fiber deep well furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Pit type reduction furnace, heating furnace advantages, characteristics and principles

2025-5-27