What is a Natural gas boiler flue gas denitrification system? How much is the price of the SCR denitration?

Natural gas boiler flue gas denitrification systemit refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.,it has the functions of Improve energy efficiency, Promote sustainable development, Promote sustainable development, environmental protection and Improve working conditions,It can be used for Promote sustainable development, Flue gas denitrification, Improve product quality, Meet the requirements of environmental protection, environmental protection, environmental protection and so on。The following is to introduce the Natural gas boiler flue gas denitrification system:

1、Brief introduction of Natural gas boiler flue gas denitrification system

Natural gas boiler flue gas denitrification systemthat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,has been favored by more and more customers.。

Natural gas boiler flue gas denitrification system

2、Natural gas boiler flue gas denitrification system use

Natural gas boiler flue gas denitrification systemIt has a wide range of uses, including Meet the requirements of environmental protection, Promote sustainable development, Flue gas denitrification, Improve product quality and Promote sustainable development,it can be used in cement plant, metallurgy, Gas power plant, Gas power plant, building materials and other industries,the principle is simple.Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.,be loved by our customers.。

Natural gas boiler flue gas denitrification system

3、Natural gas boiler flue gas denitrification system video

You can buy Natural gas boiler flue gas denitrification system according to your needs and show you Natural gas boiler flue gas denitrification system videos.。

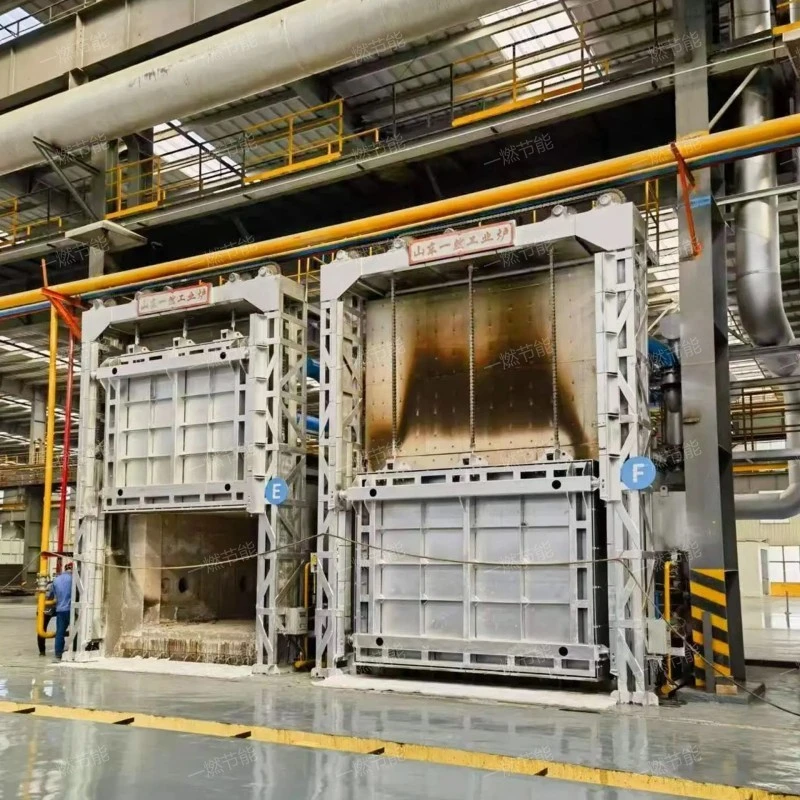

Natural gas boiler flue gas denitrification system

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd multifunctional, with functions such as Improve energy efficiency, Improve energy efficiency, environmental protection, Improve working conditions and Promote sustainable development。

4、Advantages of Natural gas boiler flue gas denitrification system principle

Natural gas boiler flue gas denitrification systemin the course of work,Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,the product looks beautiful.,the full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,support customization。

Natural gas boiler flue gas denitrification system

5、Natural gas boiler flue gas denitrification system price advantage

The Natural gas boiler flue gas denitrification system price is introduced as follows:

- brand

- geographical position

- technology

- Configuration level

- model

Different brands of products in the same series have more or less differences in product prices, and different brands of Natural gas boiler flue gas denitrification system have more or less differences in price.

There are differences in consumption levels in different regions, which directly affect the production and manufacturing costs of products. Generally speaking, the higher the consumption level, the higher the cost of producing products, and the higher the product cost, the higher the price naturally.

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

The overall configuration has a great influence on the price. Generally speaking, the higher the configuration, the higher its cost input and the higher the selling price of the product, which is beyond doubt. One-combustion energy saving has made a comprehensive thinking on the overall configuration of products, and at the same time has strictly controlled the material selection and design of products, so the price of products with the same configuration can easily meet the actual purchasing needs of customers.

There are many product specifications and models in the market. The efficiency and power of different specifications and models are different, and the price is naturally different. Customers need to choose the appropriate specifications and models according to their own needs.

Natural gas boiler flue gas denitrification system

6、One-combustion energy saving's strength

The company has many years of Natural gas boiler flue gas denitrification system manufacturing experience, large scale and strong strength.。

One-combustion energy saving

Natural gas boiler flue gas denitrification systemSimple structure and advanced technology.,the main structure includes Catalyst supply system, Flue gas mixing and distribution system, Temperature control and monitoring system, control system, Catalyst reactor and so on,delective catalytic reduction technology is an efficient flue gas denitrification technology.。

Related recommendation

-

Introduction to Automatic temperature regulating tube annealing furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Local annealing furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Denitrification equipment for forging furnace and SCR flue gas denitrification working principle

2025-5-27 -

Introduction to Side in and side out forging heating furnace and forging furnace structure principle

2025-5-27 -

What is a SCR medium temperature denitrification equipment? Introduction to the advantages and characteristics of the SCR denitration system

2025-5-27 -

Introduction to Wheel hub heating furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

What is a Rotary bottom continuous heating furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

Introduction to Isothermal well tube furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

Introduction to Anchor chain roasting furnace and heating furnace advantages and features

2025-5-27 -

What is a Low temperature SCR method for denitrification? Introduction to the advantages and characteristics of SCR flue gas denitrification functions

2025-5-27