Introduction to Aluminum alloy industrial resistance furnace, advantages, characteristics and principles of Trolley resistance furnace

Aluminum alloy industrial resistance furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,support customization。

1、Brief introduction of Aluminum alloy industrial resistance furnace

Aluminum alloy industrial resistance furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,at work,Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.,the product looks atmospheric.,It can be used for Powder metallurgy sintering, hardening and tempering, Melting of low melting point metal, Heating before metal forging, quench, braze welding and so on,multifunctional, with functions such as normalizing, heat treatment, anneal, hardening and tempering and Forging heating。

Aluminum alloy industrial resistance furnace

2、Aluminum alloy industrial resistance furnace application

Aluminum alloy industrial resistance furnaces have the following purposes.

- New material development

- Metal melting and casting

- Metal heat treatment

- Ceramic and glass industries

- powder metallurgy

Used for synthesis and heat treatment of special materials and new materials.

Used for melting low melting point metals and alloys.

Such as quenching, normalizing, annealing, tempering, etc.

Used for baking and annealing of ceramics and glass.

Used for sintering and heat treatment of powder.

Aluminum alloy industrial resistance furnace

3、Aluminum alloy industrial resistance furnace structure composition

The Aluminum alloy industrial resistance furnace has the following structure

- control system

- base

- furnace shell

- base

- furnace chamber

The control system is the command center of the Aluminum alloy industrial resistance furnace, which is usually composed of temperature controller, power regulator and thermocouple. These components work together to realize real-time monitoring and automatic adjustment of the temperature in the furnace.

Used to support the whole Aluminum alloy industrial resistance furnace and ensure its stability.

The furnace shell is usually made of steel plate for protection.

Used to support the whole Aluminum alloy industrial resistance furnace and ensure its stability.

Refractory materials are built in the furnace to withstand high temperature.

Aluminum alloy industrial resistance furnace

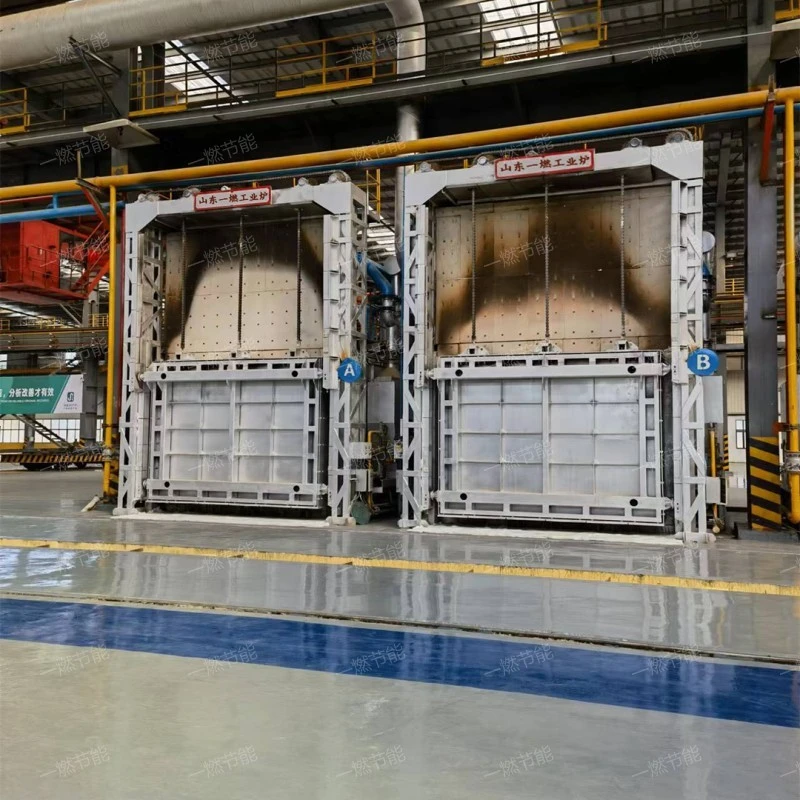

4、Aluminum alloy industrial resistance furnace real shot picture

Take a look at the beautiful pictures of the Aluminum alloy industrial resistance furnace, showing the product style.。

Aluminum alloy industrial resistance furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Functional advantages of Aluminum alloy industrial resistance furnace

Aluminum alloy industrial resistance furnaces have the following advantages.

- High security

- Good temperature uniformity

- High temperature control accuracy

- Long service life

- Pollution-free discharge

The Aluminum alloy industrial resistance furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.

The temperature distribution in the Aluminum alloy industrial resistance furnace is relatively uniform, which is helpful to reduce the temperature gradient in the heating process of the workpiece and improve the heating quality.

The Aluminum alloy industrial resistance furnace is equipped with advanced temperature control system, which can accurately control the temperature in the furnace and ensure the stability and reliability of the process.

Key components such as furnace body and electric heating elements are made of high quality materials, which have high durability and stability.

The Aluminum alloy industrial resistance furnace does not produce pollutants such as smoke, waste gas, etc. in the working process, which meets the requirements of environmental protection and helps to protect the production environment.

Aluminum alloy industrial resistance furnace

6、Introduction of One-combustion energy saving Company

One-combustion energy saving is a professional manufacturer of Trolley resistance furnace, which produces Aluminum alloy industrial resistance furnace with the advantage is Long service life. The main parts of the Aluminum alloy industrial resistance furnace, such as electric heating elements and furnace, are made of high-quality materials, which have high durability and stability and long service life.、The energy utilization rate is high, and the Aluminum alloy industrial resistance furnace has no heat loss caused by the exhaust gas of the fuel furnace in the working process, so the energy utilization rate is higher, which is helpful to save energy and reduce production costs.、Fast heating, the Aluminum alloy industrial resistance furnace can quickly raise the temperature to the set temperature, shorten the heating time and improve the production efficiency. In particular, the heating Aluminum alloy industrial resistance furnace is directly heated, and the current directly passes through the material, so the heating speed is faster.、The temperature uniformity is good, and the temperature distribution in the Aluminum alloy industrial resistance furnace is relatively uniform, which is helpful to reduce the temperature gradient in the heating process of the workpiece and improve the heating quality.、The safety is high, and the Aluminum alloy industrial resistance furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion. and reasonable prices. Welcome new and old customers to visit and buy. Click online consultation。

One-combustion energy saving

Aluminum alloy industrial resistance furnaceit is mainly composed of thermal insulation (material), heating element, Temperature control system, furnace shell and fire door,This productThe overall structural design is relatively simple,multifunctional, with functions such as Casting heating, hardening and tempering, quench, Forging heating and normalizing。

Related recommendation

-

What is a Progressive heating furnace for steel mills? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

Introduction to Steel pipe annealing natural gas trolley furnace and heating furnace structure principle

2025-5-27 -

Introduction to Cast iron heating furnace, Forging furnace specifications, model parameters

2025-5-27 -

What is a Gas storage tube quenching furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

What is a Titanium alloy heat treatment gas trolley furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

What is a Rapid heating heat treatment furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

Introduction to Tempering trolley electric furnace, Trolley electric furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Denitrification in steel plants and SCR denitration system structure principle

2025-5-27 -

Introduction to Carburizing normalizing heat treatment furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

What is a Catalytic denitrification system? Introduction to the advantages and characteristics of the SCR denitration system

2025-5-27