Introduction to Energy saving and environmentally friendly heat treatment chain furnace, Forging furnace specifications, model parameters

Energy saving and environmentally friendly heat treatment chain furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,the product looks beautiful.,it is widely used in shipping, pharmacy, electron, building materials and chemical industry,is developed and improved by One-combustion energy saving。

1、Brief introduction of Energy saving and environmentally friendly heat treatment chain furnace

Energy saving and environmentally friendly heat treatment chain furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,It has a wide range of uses, including Improve production efficiency, Metal melting and casting, Metal melting and casting, Metal tempering and Improve production efficiency。

Energy saving and environmentally friendly heat treatment chain furnace

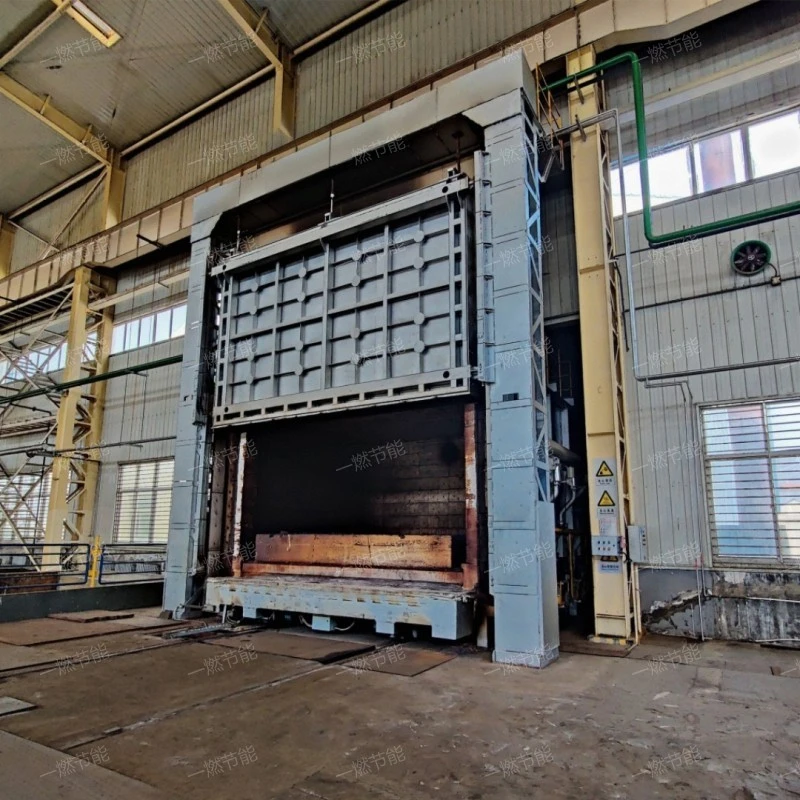

2、On-site real shot of Energy saving and environmentally friendly heat treatment chain furnace

One-combustion energy saving Energy saving and environmentally friendly heat treatment chain furnace complete specifications and models, new and old customers can choose at will, and high-definition pictures are available for customers' reference.。

Energy saving and environmentally friendly heat treatment chain furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Energy saving and environmentally friendly heat treatment chain furnace function

Energy saving and environmentally friendly heat treatment chain furnaceit has the functions of hardening and tempering, anneal, normalizing, Casting heating and quench。

Energy saving and environmentally friendly heat treatment chain furnace

4、Energy saving and environmentally friendly heat treatment chain furnace structure

The Energy saving and environmentally friendly heat treatment chain furnace structure is introduced as follows:

- combustor

- Waste heat recovery system

- convection chamber

- Radiation chamber

- ventilation system

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

The heat load of the main place for Energy saving and environmentally friendly heat treatment chain furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Energy saving and environmentally friendly heat treatment chain furnace

5、How much is the Energy saving and environmentally friendly heat treatment chain furnace?

The Energy saving and environmentally friendly heat treatment chain furnace price is introduced as follows:

- product configuration

- raw material

- product function

- Proper management mode

- product costs

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Energy saving and environmentally friendly heat treatment chain furnace are closely related. One-combustion energy saving has comprehensively measured the configuration and sales price of products when designing Energy saving and environmentally friendly heat treatment chain furnace, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

The production cost is mainly the purchase of raw materials. One-combustion energy saving attaches great importance to the purchase of raw materials to ensure the comprehensive quality of products. Only excellent raw materials can produce excellent products, and the input cost of raw materials has a direct relationship with the formulation of product prices. Under the premise of ensuring excellent product performance, One-combustion energy saving strives to reduce the input cost of products, and customers are very satisfied with this.

Energy saving and environmentally friendly heat treatment chain furnace

6、One-combustion energy saving after-sales service

Service has a starting point, and satisfaction has no end. One-combustion energy saving provides services such as free design scheme before sale, free installation and debugging of products during sale, and regular return visits after sale to solve customer problems in time. If you have special requirements for products, manufacturers also support tailor-made.。

One-combustion energy saving

Energy saving and environmentally friendly heat treatment chain furnaceThe user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.,at runtime,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.。

Related recommendation

-

What is a Fully protected continuous heat treatment furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Energy saving walking furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Galvanized steel pipe heating furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

What is a Trolley type annealing furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to High temperature push-pull trolley forging furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

What is a Annealing natural gas trolley furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

Introduction to Regenerative burner trolley furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

What is a Low temperature catalytic reduction denitrification equipment? Introduction to the advantages and characteristics of the SCR flue gas denitrification

2025-5-27 -

What is a Automatic temperature control stepper industrial furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

What is a Bright annealing heat treatment furnace? heating furnace specifications, models, and parameters

2025-5-27