What is a Regenerative gas chain heat treatment furnace? Introduction to the principle of heating furnace structure

Regenerative gas chain heat treatment furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,in the course of work,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.。

1、Brief introduction of Regenerative gas chain heat treatment furnace

Regenerative gas chain heat treatment furnaceIt is a forging heating device using gas as fuel.,the main features are energy saving and environmental protection, Easy to maintain, Stable and reliable, Easy to maintain and Easy to control,is designed by One-combustion energy saving with advanced technology。

Regenerative gas chain heat treatment furnace

2、Introduction of Regenerative gas chain heat treatment furnace characteristics

Regenerative gas chain heat treatment furnace has the following characteristics

- energy saving and environmental protection

- Strong adaptability

- Stable and reliable

- Easy to control

- Easy to maintain

As a clean energy source, natural gas produces less pollutants after combustion, which is beneficial to environmental protection. At the same time, the application of waste heat recovery system further improves the energy utilization efficiency.

The Regenerative gas chain heat treatment furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

The Regenerative gas chain heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

The structural design of the Regenerative gas chain heat treatment furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

Regenerative gas chain heat treatment furnace

3、Regenerative gas chain heat treatment furnace function

Regenerative gas chain heat treatment furnaceit has the functions of Forging heating, hardening and tempering, Casting heating, temper and quench,the main features are Strong adaptability, energy-efficient, Easy to control, energy saving and environmental protection and Easy to maintain,is a popular Regenerative gas chain heat treatment furnace,It is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,is carefully developed by One-combustion energy saving combined with advanced technology。

Regenerative gas chain heat treatment furnace

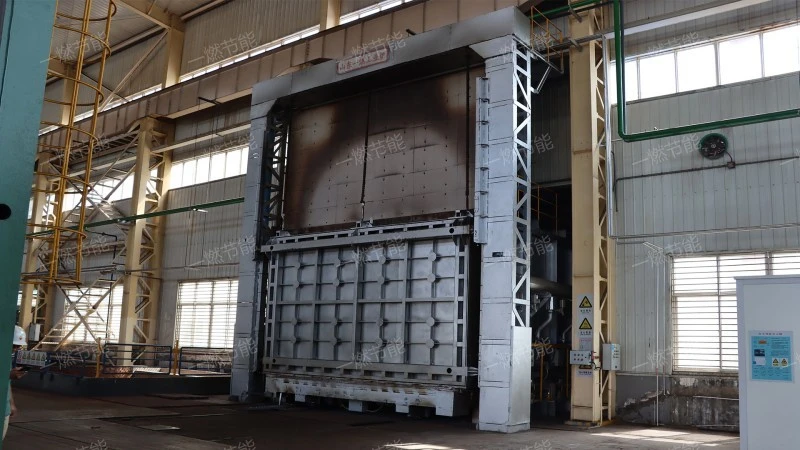

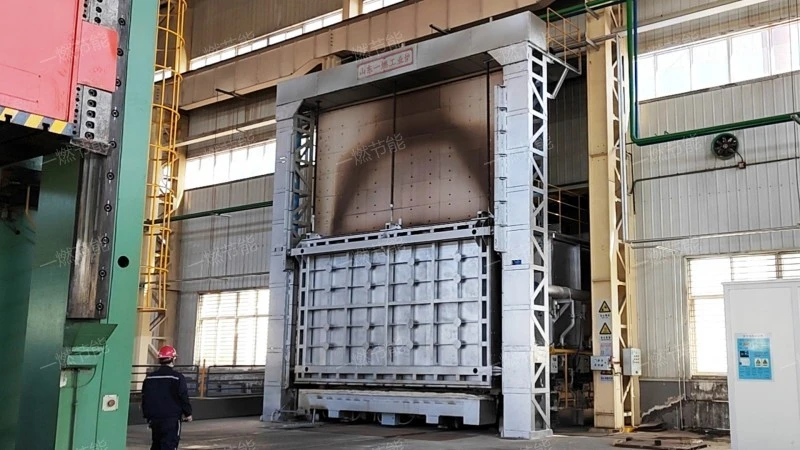

4、Regenerative gas chain heat treatment furnace real beat

The Regenerative gas chain heat treatment furnace has been upgraded, and the beauty of details is appreciated.。

Regenerative gas chain heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Regenerative gas chain heat treatment furnace performance advantage

Regenerative gas chain heat treatment furnaces have the following advantages.

- Reduce operating costs

- Extend the service life of equipment

- Rapid temperature rise

- Uniform heating

- Wide application range

The efficient combustion and waste heat recovery system of the Regenerative gas chain heat treatment furnace can significantly reduce energy consumption, thus reducing operating costs.

The Regenerative gas chain heat treatment furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Regenerative gas chain heat treatment furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

The Regenerative gas chain heat treatment furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

The Regenerative gas chain heat treatment furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

Regenerative gas chain heat treatment furnace

6、Regenerative gas chain heat treatment furnace price consultation

The Regenerative gas chain heat treatment furnace price is introduced as follows:

- market supply and demand

- Manufacturer's strength

- quality

- Model size

- Low cost of raw materials

This is one of the external factors that lead to price fluctuation. Only after fully understanding the market can we make a reasonable decision. One-combustion energy saving has a deep understanding of this factor, so the price of our Regenerative gas chain heat treatment furnace is more reasonable.

At present, there are many manufacturers of products on the market, some of which belong to direct selling manufacturers and some belong to middlemen. Direct selling manufacturers will cost less than middlemen, so the quotation for products will be lower. Therefore, it is recommended that customers buy products from direct selling manufacturers of Regenerative gas chain heat treatment furnace. In addition, even direct selling manufacturers have different capital status, strength level and technology, and the quotation for Regenerative gas chain heat treatment furnace will be different.

Quality is one of the fundamental and important factors that affect the price. Usually, the better the quality of the Regenerative gas chain heat treatment furnace, the higher its price, and the quality is mainly affected by the manufacturing process, raw material materials, workers' experience and other factors. Therefore, if customers want to buy products with better quality, they can conduct on-the-spot visits to the product manufacturers to learn more about the scale, manufacturing process and production capacity of the manufacturers, so as to comprehensively judge the quality of the products.

One-combustion energy saving is a professional production center in Shandong(Province), the Regenerative gas chain heat treatment furnace of various specifications and models manufactured are affordable, reliable in quality, good in performance and perfect after-sales, which is a good choice for everyone to buy Regenerative gas chain heat treatment furnace.

If the cost of the product is high, the selling price of the product will be high, so the cost input is an important factor that causes the price change of the Regenerative gas chain heat treatment furnace.

Regenerative gas chain heat treatment furnace

Regenerative gas chain heat treatment furnaceit has the characteristics of energy saving and environmental protection, energy-efficient, Strong adaptability, Stable and reliable and Stable and reliable,It is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

Related recommendation

-

Introduction to High temperature forging furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Industrial forging furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

调质台车锻造加热炉

2023-08-05 -

Introduction to Carburizing normalizing heating furnace and heating furnace advantages and features

2025-5-27 -

Introduction to Annular well quenching furnace, forging furnace specifications, model parameters

2025-5-27 -

Introduction to Electric heating forging furnace, Trolley electric heating furnace specifications, model parameters

2025-5-27 -

What is a Large roller furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

Introduction to Mobile trolley forging furnace and forging furnace working principle

2025-5-27 -

Introduction to Stick type continuous heat treatment furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

What is a Chain track heating furnace? How much is the price of the Forging furnace?

2025-5-27