What is a Rail gas trolley furnace? Introduction to the principle of heating furnace structure

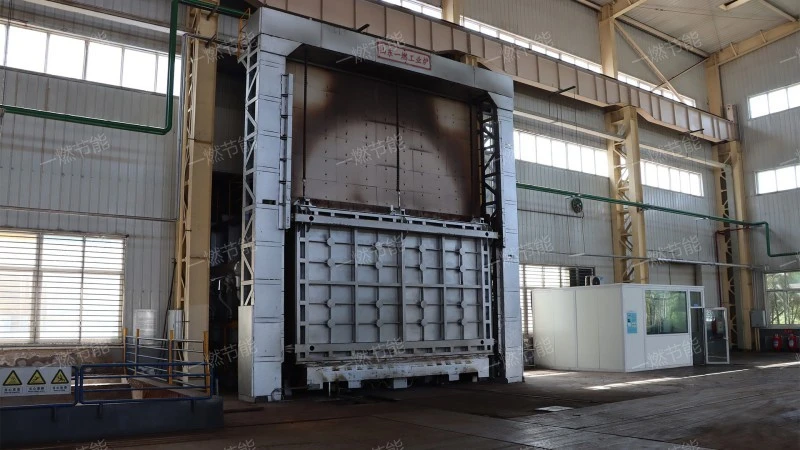

Rail gas trolley furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,is a kind of high quality and low price Rail gas trolley furnace。The following is to introduce the Rail gas trolley furnace:

1、Brief introduction of Rail gas trolley furnace

Rail gas trolley furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,is carefully developed by One-combustion energy saving combined with advanced technology。

Rail gas trolley furnace

2、Rail gas trolley furnace function

Rail gas trolley furnaceit has the functions of Forging heating, anneal, quench, hardening and tempering and Forging heating,is developed and improved by One-combustion energy saving。

Rail gas trolley furnace

3、Introduction of advantages of Rail gas trolley furnace

The advantages of Rail gas trolley furnace are as follows:

- Multiple fuel options

- easy to operate

- Reduce operating costs

- Intelligent control

- Efficient combustion

Although the Rail gas trolley furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

The operation interface of the Rail gas trolley furnace is friendly and easy for operators to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.

The efficient combustion and waste heat recovery system of the Rail gas trolley furnace can significantly reduce energy consumption, thus reducing operating costs.

The Rail gas trolley furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

The Rail gas trolley furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

Rail gas trolley furnace

4、Introduction of Rail gas trolley furnace characteristics

Rail gas trolley furnace has the following characteristics

- Easy to control

- Efficient heating

- energy saving and environmental protection

- Strong adaptability

- Efficient heating

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

The Rail gas trolley furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

As a clean energy source, natural gas produces less pollutants after combustion, which is beneficial to environmental protection. At the same time, the application of waste heat recovery system further improves the energy utilization efficiency.

The Rail gas trolley furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

The Rail gas trolley furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

Rail gas trolley furnace

5、Rail gas trolley furnace principle

Rail gas trolley furnaceat work,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,it is widely used in war industry, surface treatment, metallurgy, aerospace and building materials,The price is low and affordable,reliable quality。

Rail gas trolley furnace

6、Brief introduction of Rail gas trolley furnace

Rail gas trolley furnaceIt is a forging heating device using gas as fuel.,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,the product looks beautiful.,the advantage is The use of clean and environmentally friendly natural gas as fuel effectively avoids the adverse effects of chemical reactions between impurities such as coal-fired furnaces and forgings during heating. At the same time, natural gas has high calorific value and high combustion temperature, and the combustion temperature can be further increased by preheating air and fuel. In addition, the gas forging heating furnace also has good heat loss control ability and intelligent control system, which can accurately adjust the ratio of air to natural gas, ensure full combustion of natural gas, and reduce mechanical incomplete combustion and chemical incomplete combustion.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.,is a kind of Rail gas trolley furnace manufactured by One-combustion energy saving。

Rail gas trolley furnace

Rail gas trolley furnacemultifunctional, with functions such as hardening and tempering, normalizing, heat treatment, Casting heating and quench,Easy to maintain,energy-efficient,Strong adaptability,energy saving and environmental protection,Easy to control,it is usually composed of ventilation system, recovery of waste heat, combustor, convection chamber and furnace chamber。

Related recommendation

-

What is a Local annealing heat treatment furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Air quenching natural gas trolley furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Medium sized trolley forging heating furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

台车式工业退火炉

2023-07-07 -

Brief introduction and advantages of High manganese steel trolley heating furnace

2025-6-18 -

What is a Chain plate automatic heating furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Split type well type heat treatment furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Energy saving box type electric furnace, introduction to Trolley electric heating furnace function advantages and characteristics

2025-5-27 -

What is a Chain type roasting furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Casting forging furnace and heating furnace advantages and features

2025-5-27