What is a Annealing furnace multi chamber type? Introduction to the advantages, characteristics, and principles of the forging furnace

Annealing furnace multi chamber typeIt is a forging heating device using gas as fuel.,is a Annealing furnace multi chamber type,multifunctional, with functions such as normalizing, hardening and tempering, quench, Casting heating and temper,It is a product series that integrates Metal forging heating, Energy conservation and environmental protection, Metal melting and casting, Metal tempering and Metal heat treatment,has been favored by more and more customers.。The following is to introduce the Annealing furnace multi chamber type:

1、Brief introduction of Annealing furnace multi chamber type

Annealing furnace multi chamber typeIt is an efficient, energy-saving and environment-friendly metal heating device.,it is widely used in shipping, material, heat treatment, surface treatment and electron,Simple structure and reliable operation.,the main structure includes Radiation chamber, combustor, convection chamber, ventilation system and recovery of waste heat。

Annealing furnace multi chamber type

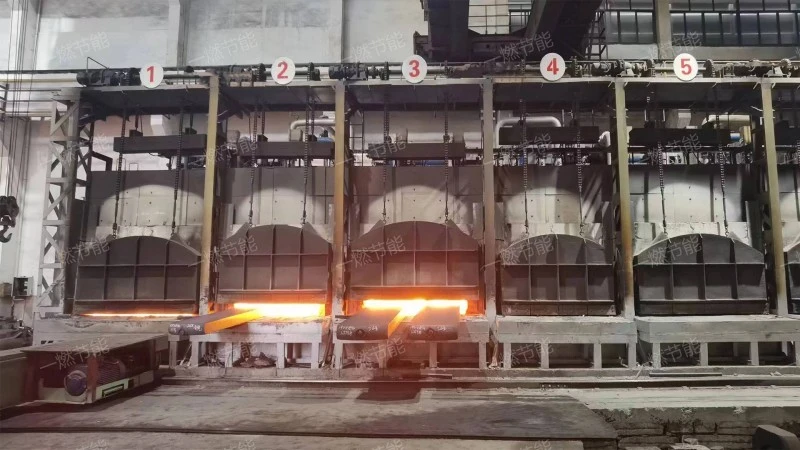

2、Annealing furnace multi chamber type HD real shot

Annealing furnace multi chamber type HD factory map, all-round shooting, for our customers to visit.。

Annealing furnace multi chamber type

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Annealing furnace multi chamber type characteristics

The Annealing furnace multi chamber type features are as follows:

- Efficient heating

- energy saving and environmental protection

- Strong adaptability

- Efficient heating

- Easy to control

The Annealing furnace multi chamber type can heat the metal material to the required temperature in a short time and improve the production efficiency.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the Annealing furnace multi chamber type further improves energy utilization efficiency and reduces energy consumption and emissions.

The Annealing furnace multi chamber type can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The Annealing furnace multi chamber type can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

The combustion system and ventilation system of the Annealing furnace multi chamber type can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

Annealing furnace multi chamber type

4、Annealing furnace multi chamber type field real shot

On-site aerial photography of Annealing furnace multi chamber type。

Annealing furnace multi chamber type

As you can see from the live video.,One-combustion energy saving at runtime,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

5、Annealing furnace multi chamber type price concessions

The Annealing furnace multi chamber type price is introduced as follows:

- Company size

- region

- Brand strength

- Product technology

- marketing channel

Our factory is a direct selling manufacturer of Annealing furnace multi chamber type, with independent production and processing facilities, few circulation links and low circulation cost.

Different provinces and regions have different consumption levels, different market positioning and different prices.

At present, there are various brands of Annealing furnace multi chamber type in Shandong(Province). The performance, quality and after-sales of products under different brands are different, and the prices of Annealing furnace multi chamber type are different.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

Annealing furnace multi chamber type

6、company strength

The company has many years of Annealing furnace multi chamber type manufacturing experience, large scale and strong strength.。

One-combustion energy saving

Annealing furnace multi chamber typethe advantage is Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.,Widely used in Improve production efficiency, Energy conservation and environmental protection, Metal heat treatment, Metal melting and casting and Metal tempering,is a common Annealing furnace multi chamber type。

Related recommendation

-

What is a Chain belt heating furnace? How much is the price of the forging furnace?

2025-5-27 -

台车焙烧炉

2023-05-06 -

What is a Trolley type annealing furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Electric heating industrial annealing furnace, introduction to Trolley electric heating furnace function advantages and characteristics

2025-5-27 -

Introduction to Steel plant denitrification, advantages, characteristics and principles of SCR denitration system

2025-5-27 -

Introduction to Quenching well type quenching furnace and Forging furnace advantages and features

2025-5-27 -

Introduction to Deep well reduction furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Round tube heat treatment furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Continuous roller bottom heating furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Denitrification of flue gas inside the furnace, SCR denitration specifications, model parameters

2025-5-27