What is a Forging and quenching industrial furnace? How much is the price of the heating furnace?

Forging and quenching industrial furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,is carefully developed by One-combustion energy saving combined with advanced technology。

1、Brief introduction of Forging and quenching industrial furnace

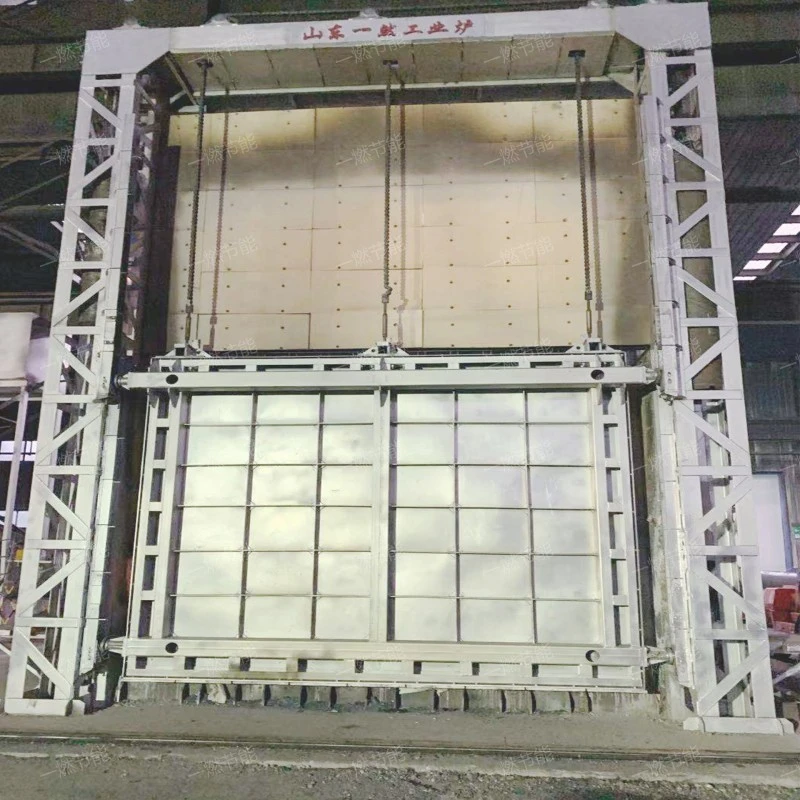

Forging and quenching industrial furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,the main structure includes furnace chamber, Radiation chamber, recovery of waste heat, recovery of waste heat, ventilation system and so on,was developed and designed by One-combustion energy saving。

Forging and quenching industrial furnace

2、Forging and quenching industrial furnace function

Forging and quenching industrial furnaceit has the functions of anneal, hardening and tempering, Casting heating, temper and heat treatment,features include energy saving and environmental protection, Stable and reliable, Strong adaptability, energy-efficient and energy saving and environmental protection,structure mainly includes: Radiation chamber, combustor, furnace chamber, convection chamber, ventilation system and so on,productThe overall structural design is simple and novel.,it can be used in machinery, light industry, Machinery manufacturing, petroleum, building materials and other industries,It is a product series that integrates Metal tempering, Metal forging heating, Energy conservation and environmental protection, Metal melting and casting and Metal melting and casting。

Forging and quenching industrial furnace

3、Forging and quenching industrial furnace use

The purpose of Forging and quenching industrial furnace is introduced as follows:

- Metal forging heating

- Metal forging heating

- Metal heat treatment

- Energy conservation and environmental protection

- Metal tempering

The Forging and quenching industrial furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

The Forging and quenching industrial furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

In addition to forging heating, Forging and quenching industrial furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

The Forging and quenching industrial furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

By properly heating and cooling the metal material, the Forging and quenching industrial furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

Forging and quenching industrial furnace

4、Forging and quenching industrial furnace structure

The Forging and quenching industrial furnace structure is introduced as follows:

- furnace chamber

- convection chamber

- ventilation system

- combustor

- Waste heat recovery system

A space for holding metallic materials for heating.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Forging and quenching industrial furnace

5、Forging and quenching industrial furnace price concessions

The Forging and quenching industrial furnace price is introduced as follows:

- service

- specifications and models

- Overall configuration

- Company size

- Service factor

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Forging and quenching industrial furnace price and service can meet the actual needs of customers.

Because the specifications and models of products are different, their specifications and configurations are not the same. As we all know, the cost of products with high configuration will be higher, and vice versa, because there is a close relationship between product sales price and specifications and models.

The overall configuration has a great influence on the price. Generally speaking, the higher the configuration, the higher its cost input and the higher the selling price of the product, which is beyond doubt. One-combustion energy saving has made a comprehensive thinking on the overall configuration of products, and at the same time has strictly controlled the material selection and design of products, so the price of products with the same configuration can easily meet the actual purchasing needs of customers.

Although there are many manufacturers of products in Jinan, Shandong province, there are certain differences in the scale and strength of each manufacturer. Some manufacturers are large in scale and strength, some are small in scale, and some manufacturers do not have their own production workshops and belong to middlemen. Relatively speaking, the prices of products formulated by middlemen are higher.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Forging and quenching industrial furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Forging and quenching industrial furnace price can meet the purchasing needs of customers.

Forging and quenching industrial furnace

6、Brief introduction of One-combustion energy saving

One-combustion energy saving has many years of experience in Forging and quenching industrial furnace production, and is a professional Forging and quenching industrial furnace manufacturer. With favorable Forging and quenching industrial furnace price, stable product quality, rich product series and perfect after-sales service system, the company strives to become an advanced Forging and quenching industrial furnace manufacturer in Jinan.。

One-combustion energy saving

Forging and quenching industrial furnaceIt is a forging heating device using gas as fuel.,the product looks beautiful.。

Related recommendation

-

Introduction to Top fired forging box furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Low temperature well type heat treatment furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Electric quenching furnace, Trolley electric heating furnace specifications, model parameters

2025-5-27 -

Introduction to Environmentally friendly chain heating furnace and Forging furnace working principle

2025-5-27 -

What is a Pit type high-temperature quenching furnace? How much is the price of the forging furnace?

2025-5-27 -

Introduction to Double pass mold shell roasting furnace and heating furnace working principle

2025-5-27 -

Introduction to Casting resistance heating furnace, advantages, characteristics and principles of Trolley resistance furnace

2025-5-27 -

Introduction to Aluminum alloy heat treatment resistance furnace and Trolley resistance heating furnace working principle

2025-5-27 -

Introduction to Automatic feeding and unloading heating furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Automatic temperature control step advance and retreat furnace, forging furnace advantages, characteristics and principles

2025-5-27