Introduction to Carbon steel discharger and unloader advantages and features

Carbon steel dischargermainly used for dust removal equipment, dust discharge, air supply and other equipment feeding process.,It has strong impact resistance, can bear the impact force generated by materials during transportation, and ensures the stable operation of the equipment.、The bearing and gear box are far away from the valve body to avoid the influence of high temperature dust. At the same time, the front and rear end covers have good sealing performance, which effectively prevents dust from leaking out and prolongs the service life of moving parts and lubrication systems.、The design of special sealing structure enables the Carbon steel discharger to maintain high sealing performance during transportation, reduce material leakage and improve transportation efficiency.、Can evenly and continuously feed materials into the clinker pipe to ensure the stability and continuity of material transportation.、According to users' needs, special motors, such as explosion-proof, frequency modulation, speed regulation and marine motors, are configured to meet users' special requirements. The material of the blade can also be specially processed according to the needs of users.,at the start of the operation,Based on a rotor with several blades rotating in a cylindrical casing. When the rotor rotates, materials fall from the upper hopper and are filled in the spaces between the blades. With the rotation of the impeller, the material is conveyed to the lower part and discharged. At the same time, the pressure equalizing exhaust port on the side of the machine body can exhaust the high-pressure gas generated by the rotation of the impeller, so as to reduce the phenomenon of gas ejection and ensure the smooth falling of materials.,is developed and improved by hyde powder。The following is to introduce the Carbon steel discharger:

1、Brief introduction of Carbon steel discharger

Carbon steel dischargeris widely used in powder engineering, pneumatic conveying and dust removal system.。

Carbon steel discharger

2、Carbon steel discharger function

Carbon steel dischargerit has the functions of prevent gas or dust leakage, continuously and uniformly feed or discharge., ensure air tightness of the system, material handling and equipment feeding,it is an ideal choice for customers to buy Carbon steel discharger。

Carbon steel discharger

3、Structural characteristics of Carbon steel discharger

The Carbon steel discharger structure is introduced as follows:

- Motor and transmission device

- sealing element

- impeller

- Rotor and shell

- Equalizing exhaust port

The motor provides power for the Carbon steel discharger, and the power is transmitted to the impeller through transmission devices (such as gears and sprockets) to make it rotate. The transmission device shall be designed to ensure smooth and reliable power transmission.

Seals are used to ensure the sealing performance of the Carbon steel discharger in the working process and prevent material leakage and gas backflow. High-quality seals can improve the working efficiency and service life of equipment.

Impeller is the key part of the Carbon steel discharger to realize material transportation. Its structural design is reasonable, which can ensure the uniform distribution of materials in the spaces between the impellers and be transported smoothly with the rotation of the impellers.

The rotor is the core component of the Carbon steel discharger, and usually consists of several blades, which rotate in the cylindrical casing. Materials fall from the upper hopper and are filled in the spaces between the blades. With the rotation of the impeller, they are transported to the lower part and discharged from the shell to protect the internal mechanism and seal, and prevent the leakage of materials and the entry of external impurities.

The side of the Carbon steel discharger body is provided with a pressure equalizing exhaust port, which can exhaust the high-pressure gas brought by the rotation of the impeller, reduce the phenomenon of gas ejection, and facilitate the smooth falling of materials.

Carbon steel discharger

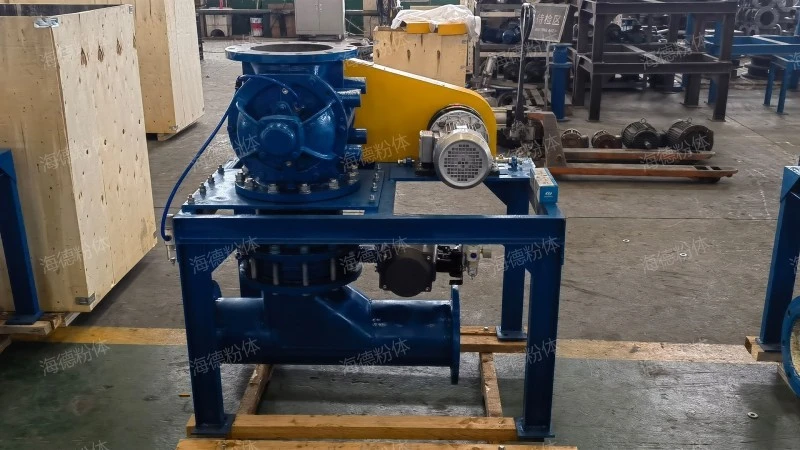

4、Carbon steel discharger HD real shot

hyde powder provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Carbon steel discharger production process and production site, and gain favorable comments and recognition from customers.。

Carbon steel discharger

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. it can be used in metallurgy, dock, building materials, chemical raw material, building materials cement and other industries。

5、Carbon steel discharger principle

Carbon steel dischargerat work,The motor reducer drives the impeller to rotate in the cylindrical casing. Materials fall from the upper hopper and are filled in the spaces between the impellers. With the rotation of the impellers, the materials are transported to the lower part and discharged. At the same time, the exhaust port exhausts the high-pressure gas generated by the rotation of the impeller, which reduces the phenomenon of gas ejection and ensures the continuity and stability of material transportation.,it is widely used in plastic metallurgy, chemical industry, energy mining industry, grain processing, mine and other industries,has been favored by more and more customers.。

Carbon steel discharger

6、Carbon steel discharger use

Carbon steel dischargerIt has a wide range of uses, including continuously and uniformly feed or discharge., blowing-in, material handling, prevent gas or dust leakage and blowing-in。

Carbon steel discharger

Carbon steel dischargerthe principle is simple.Based on a rotor with several blades rotating in a cylindrical casing. When the rotor rotates, materials fall from the upper hopper and are filled in the spaces between the blades. With the rotation of the impeller, the material is conveyed to the lower part and discharged. At the same time, the pressure equalizing exhaust port on the side of the machine body can exhaust the high-pressure gas generated by the rotation of the impeller, so as to reduce the phenomenon of gas ejection and ensure the smooth falling of materials.,It is mostly used in ensure air tightness of the system, continuously and uniformly feed or discharge., equipment feeding, dust removal equipment discharges dust., material handling, prevent gas or dust leakage and so on,Structure consists of rotor and shell, impeller, sealing element, protective devices (such as sprockets, sprocket covers, etc.), motor reducing gear and so on。

Related recommendation

-

What is a Automatic unpacking pneumatic conveying system? How much is the price of the Material conveying?

2025-5-26 -

What is a Measurement, weighing, pneumatic conveying? Introduction to the advantages, characteristics, and principles of the pneumatic conveying system

2025-5-26 -

What is a Environmentally friendly and dust-free pneumatic conveying equipment? Introduction to the advantages and characteristics of the Pneumatic conveying equipment

2025-5-26 -

Introduction to Activated carbon powder pneumatic conveying equipment, pneumatic conveying advantages, characteristics and principles

2025-5-26 -

What is a Lithium carbonate pneumatic conveying equipment? Introduction to the advantages and characteristics of the Pneumatic conveying equipment

2025-5-26 -

Introduction to Molybdenum oxide pneumatic conveying, introduction to pneumatic conveying system function advantages and characteristics

2025-5-26 -

Introduction to Particle material pneumatic conveying system, pneumatic conveying system advantages, characteristics and principles

2025-5-26 -

Introduction to HDSR350V Roots Vacuum Pump Equipment, Roots Blower specifications, model parameters

2025-5-26 -

Introduction to HDSR200V roots vacuum pump and the roots vacuum pump advantages and features

2025-5-26 -

What is a Lysine pneumatic conveying? pneumatic conveying system specifications, models, and parameters

2025-5-26