Introduction to Energy-saving star unloader, how much is the price of the unloader?

Energy-saving star unloaderis widely used in powder engineering, pneumatic conveying and dust removal system.,is a Energy-saving star unloader。

1、Brief introduction of Energy-saving star unloader

Energy-saving star unloaderis the main equipment for conveying bulk materials.。

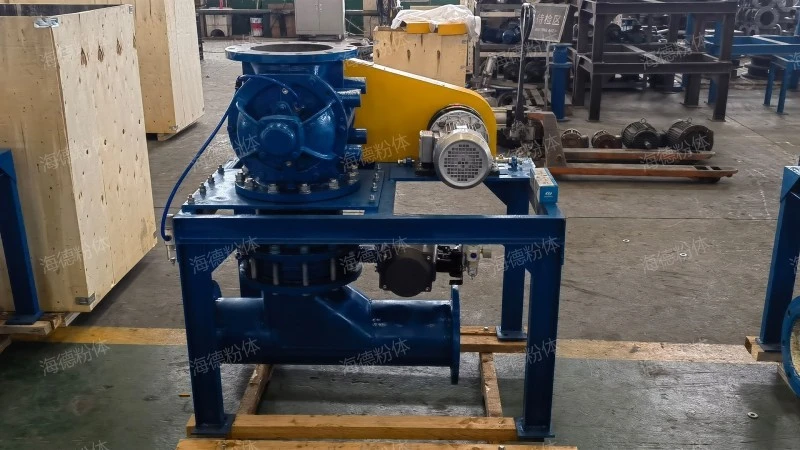

Energy-saving star unloader

2、Energy-saving star unloader application

Energy-saving star unloaderIt is a product series that integrates prevent gas or dust leakage, dust removal equipment discharges dust., blowing-in, equipment feeding and prevent gas or dust leakage,at work,The driving device drives the rotor to rotate in the cylindrical casing, and the material falls from the upper hopper, which is filled in the spaces between the blades and discharged with the rotation of the blades to the lower part. The side of the machine body is provided with a pressure equalizing exhaust port, which can exhaust the high-pressure gas brought by the rotation of the impeller, reduce the phenomenon of gas ejection, and facilitate the smooth falling of materials.,it mainly includes rotor and shell, protective devices (such as sprockets, sprocket covers, etc.), vent, motor and transmission device and sealing element,This productThe overall structural design is relatively simple and compact.,the product looks atmospheric.,is designed by hyde powder with advanced technology。

Energy-saving star unloader

3、Energy-saving star unloader function

Energy-saving star unloadermultifunctional, with functions such as prevent gas or dust leakage, ensure air tightness of the system, continuously and uniformly feed or discharge., continuously and uniformly feed or discharge. and dust removal equipment discharges dust.,the product looks beautiful.,is an excellent quantitative supply equipment designed for the purpose of supplying powder.,the main features are low noise, easy maintenance, high wear resistance, run smoothly and handsome appearance,Impeller, bushing and other key components are made of high-quality wear-resistant materials, which can withstand the friction and wear during material transportation and prolong the service life of the equipment.、The structural design makes its maintenance relatively simple, and it is easy to carry out daily inspection and troubleshooting.、Excellent sealing structure, preventing dust from leaking out and prolonging the service life of motor parts and lubrication system.、It is suitable for hard and abrasive powder, and the replaceable bushing is arranged in the casing to improve the service life and facilitate maintenance and replacement.、Using the principle of planetary rotation, the input and output shafts are on the same axis, which has compact structure, small volume and light weight.。

Energy-saving star unloader

4、Energy-saving star unloader structure

The Energy-saving star unloader has the following structure

- Motor and transmission device

- Equalizing exhaust port

- sealing element

- impeller

- Rotor and shell

The motor provides power for the Energy-saving star unloader, and the power is transmitted to the impeller through transmission devices (such as gears and sprockets) to make it rotate. The transmission device shall be designed to ensure smooth and reliable power transmission.

The side of the Energy-saving star unloader body is provided with a pressure equalizing exhaust port, which can exhaust the high-pressure gas brought by the rotation of the impeller, reduce the phenomenon of gas ejection, and facilitate the smooth falling of materials.

Seals are used to ensure the sealing performance of the Energy-saving star unloader in the working process and prevent material leakage and gas backflow. High-quality seals can improve the working efficiency and service life of equipment.

Impeller is the key part of the Energy-saving star unloader to realize material transportation. Its structural design is reasonable, which can ensure the uniform distribution of materials in the spaces between the impellers and be transported smoothly with the rotation of the impellers.

The rotor is the core component of the Energy-saving star unloader, and usually consists of several blades, which rotate in the cylindrical casing. Materials fall from the upper hopper and are filled in the spaces between the blades. With the rotation of the impeller, they are transported to the lower part and discharged from the shell to protect the internal mechanism and seal, and prevent the leakage of materials and the entry of external impurities.

Energy-saving star unloader

5、Energy-saving star unloader working site

hyde provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Energy-saving star unloader production process and production site, and gain favorable comments and recognition from customers.。

Energy-saving star unloader

As you can see from the live video.,hyde powder the principle is simple.The motor reducer drives the impeller to rotate in the cylindrical casing. Materials fall from the upper hopper and are filled in the spaces between the impellers. With the rotation of the impellers, the materials are transported to the lower part and discharged. At the same time, the exhaust port exhausts the high-pressure gas generated by the rotation of the impeller, which reduces the phenomenon of gas ejection and ensures the continuity and stability of material transportation.。

6、hyde introduced

hyde powder, as one of the professional and powerful Energy-saving star unloader manufacturers in jinan, Shandong province, produces Energy-saving star unloader with reliable quality, affordable price and perfect after-sales, which have been successfully practiced in many processing plants at home and abroad.。

hyde

Energy-saving star unloaderthe product looks beautiful.,is a popular Energy-saving star unloader。

Related recommendation

-

Introduction to Ore sand transportation, pneumatic conveying system specifications, model parameters

2025-5-26 -

Introduction to Sulfur dioxide powder pneumatic conveying equipment, how much is the price of the pneumatic conveying system?

2025-5-26 -

What is a Pneumatic conveying of sludge particles? Introduction to the advantages and characteristics of Pneumatic conveying equipment functions

2025-5-26 -

Introduction to Small bag feeding pneumatic conveying equipment, how much is the price of the pneumatic conveying?

2025-5-26 -

Introduction to Pyrolysis gas pressurized three blade Roots blower and blower working principle

2025-5-26 -

Introduction to Insurance powder conveying, how much is the price of the Material conveying?

2025-5-26 -

What is a Anti-jamming rotary discharger? How much is the price of the unloader?

2025-5-26 -

What is a Acid and alkali resistant Roots vacuum pump equipment? Introduction to the advantages and characteristics of blower functions

2025-5-26 -

Introduction to Bread flour pneumatic conveying equipment and Powder pneumatic conveying working principle

2025-5-26 -

Introduction to Metal iron powder conveying system and Powder pneumatic conveying working principle

2025-5-26