Introduction to DN200 rotary discharger and unloader structure principle

DN200 rotary dischargeris an excellent quantitative supply equipment designed for the purpose of supplying powder.,it is widely used in mine, building materials, building materials cement, metallurgy, mine and other industries。

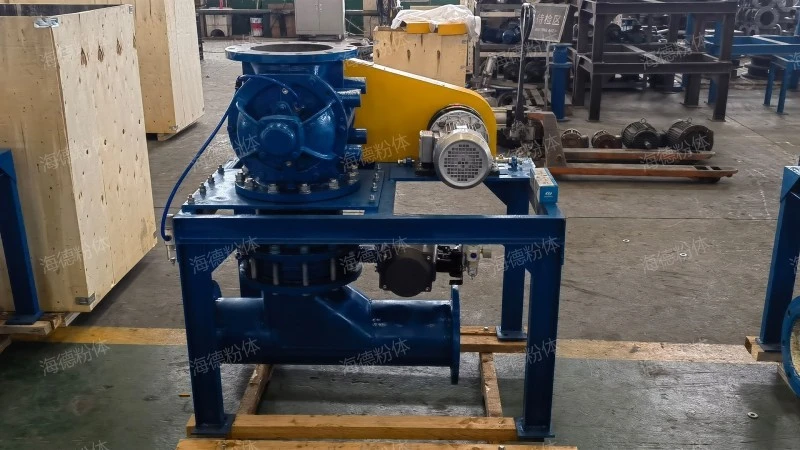

1、Brief introduction of DN200 rotary discharger

DN200 rotary dischargeris an efficient and flexible material conveying equipment.,is a popular DN200 rotary discharger,The transmission is stable and the noise is low, which provides good conditions for working environment.、According to users' needs, special motors, such as explosion-proof, frequency modulation, speed regulation and marine motors, are configured to meet users' special requirements. The material of the blade can also be specially processed according to the needs of users.、The structure design is reasonable, which is convenient for daily maintenance and overhaul. At the same time, its good sealing performance also reduces the complexity and frequency of maintenance work.、Using the principle of planetary rotation, the input and output shafts are on the same axis, which has compact structure, small volume and light weight.、The key components inside the equipment, such as impeller and bushing, are made of excellent materials and have high wear resistance, which can meet the needs of long-term and high-strength material transportation.。

DN200 rotary discharger

2、DN200 rotary discharger application

DN200 rotary dischargerMainly used forequipment feeding,continuously and uniformly feed or discharge.,prevent gas or dust leakage,blowing-in andensure air tightness of the system,as an important bulk material conveying equipment,is a device for discharging materials, which discharges materials from containers by specific mechanical or pneumatic means.。

DN200 rotary discharger

3、DN200 rotary discharger video detail

The following is the live video of DN200 rotary discharger designed and produced by hyde for users, from which we can see the the advantage is The structural design makes its maintenance relatively simple, and it is easy to carry out daily inspection and troubleshooting.、Due to the use of high-quality materials and advanced technology, the service life of the DN200 rotary discharger is longer, reducing the frequency of replacement and maintenance.、Excellent sealing structure, preventing dust from leaking out and prolonging the service life of motor parts and lubrication system.、The design of special sealing structure enables the DN200 rotary discharger to maintain high sealing performance during transportation and reduce material leakage and gas reflux.、With automatic locking mechanism and electric push rod with two-way insurance system, the work is reliable, stable and flexible. of hyde powderproduce的DN200 rotary discharger.。

DN200 rotary discharger

As you can see from the live video.,hyde powder it is widely used in building materials, chemical industry, grain processing, chemical raw material and plastic metallurgy。

4、Advantages of DN200 rotary discharger principle

DN200 rotary dischargerat the start of the operation,The driving device drives the rotor to rotate in the cylindrical casing, and the material falls from the upper hopper, which is filled in the spaces between the blades and discharged with the rotation of the blades to the lower part. The side of the machine body is provided with a pressure equalizing exhaust port, which can exhaust the high-pressure gas brought by the rotation of the impeller, reduce the phenomenon of gas ejection, and facilitate the smooth falling of materials.,Using the principle of planetary rotation, the input and output shafts are on the same axis and directly connected with the motor, which makes the whole structure compact, beautiful and novel, small in size and light in weight.、The design of special sealing structure enables the DN200 rotary discharger to maintain high sealing performance during transportation and reduce material leakage and gas reflux.、The bearing and gear box are far away from the valve body to avoid the influence of high temperature dust. At the same time, the front and rear end covers have good sealing performance, which effectively prevents dust from leaking out and prolongs the service life of moving parts and lubrication systems.、The design of special sealing structure enables the DN200 rotary discharger to maintain high sealing performance during transportation, reduce material leakage and improve transportation efficiency.、Due to the use of high-quality materials and advanced technology, the service life of the DN200 rotary discharger is longer, reducing the frequency of replacement and maintenance.,Widely used incontinuously and uniformly feed or discharge.,prevent gas or dust leakage,blowing-in,dust removal equipment discharges dust.,material handling and so on,it has the functions of prevent gas or dust leakage, dust removal equipment discharges dust., blowing-in, prevent gas or dust leakage and continuously and uniformly feed or discharge.,is a DN200 rotary discharger。

DN200 rotary discharger

5、DN200 rotary discharger structure composition

The DN200 rotary discharger structure is introduced as follows:

- sealing element

- impeller

- Rotor and shell

- Equalizing exhaust port

- Motor and transmission device

Seals are used to ensure the sealing performance of the DN200 rotary discharger in the working process and prevent material leakage and gas backflow. High-quality seals can improve the working efficiency and service life of equipment.

Impeller is the key part of the DN200 rotary discharger to realize material transportation. Its structural design is reasonable, which can ensure the uniform distribution of materials in the spaces between the impellers and be transported smoothly with the rotation of the impellers.

The rotor is the core component of the DN200 rotary discharger, and usually consists of several blades, which rotate in the cylindrical casing. Materials fall from the upper hopper and are filled in the spaces between the blades. With the rotation of the impeller, they are transported to the lower part and discharged from the shell to protect the internal mechanism and seal, and prevent the leakage of materials and the entry of external impurities.

The side of the DN200 rotary discharger body is provided with a pressure equalizing exhaust port, which can exhaust the high-pressure gas brought by the rotation of the impeller, reduce the phenomenon of gas ejection, and facilitate the smooth falling of materials.

The motor provides power for the DN200 rotary discharger, and the power is transmitted to the impeller through transmission devices (such as gears and sprockets) to make it rotate. The transmission device shall be designed to ensure smooth and reliable power transmission.

DN200 rotary discharger

6、Working principle of DN200 rotary discharger

DN200 rotary dischargerat runtime,Based on a rotor with several blades rotating in a cylindrical casing. When the rotor rotates, materials fall from the upper hopper and are filled in the spaces between the blades. With the rotation of the impeller, the material is conveyed to the lower part and discharged. At the same time, the pressure equalizing exhaust port on the side of the machine body can exhaust the high-pressure gas generated by the rotation of the impeller, so as to reduce the phenomenon of gas ejection and ensure the smooth falling of materials.,it mainly includes impeller, motor and transmission device, equalizing exhaust port, main valve (including shell, end cover, impeller, sealing structure, etc.) and vent,usually used in energy mining industry, dock, mine, plastic metallurgy, chemical raw material and other fields,is carefully developed by hyde combined with advanced technology。

DN200 rotary discharger

DN200 rotary dischargeris a DN200 rotary discharger,It has a wide range of uses, including equipment feeding, material handling, blowing-in, dust removal equipment discharges dust. and prevent gas or dust leakage。

Related recommendation

-

Introduction to Aluminum hydroxide powder conveying system, advantages, characteristics and principles of Powder pneumatic conveying

2025-5-26 -

Introduction to Three element positive electrode material conveying equipment, advantages, characteristics and principles of Powder pneumatic conveying

2025-5-26 -

Introduction to Huangsha pneumatic conveying equipment and Powder conveying working principle

2025-5-26 -

What is a Negative pressure nitrogen circulation conveying equipment? Introduction to the advantages, characteristics, and principles of the pneumatic conveying system

2025-5-26 -

Introduction to Electric lime pneumatic conveying, pneumatic conveying specifications, model parameters

2025-5-26 -

Introduction to Automatic unpacking pneumatic conveying, how much is the price of the pneumatic conveying?

2025-5-26 -

What is a HDV type silo ash conveying pump? Introduction to the principle of bin pump structure

2025-5-26 -

Introduction to Concentrated phase bin pump pneumatic conveying and pneumatic conveying system advantages and features

2025-5-26 -

Introduction to Dense group type Roots blower, how much is the price of the Three leaf Roots blower?

2025-5-26 -

What is a All-mechanical sealed three-leaf Roots vacuum pump? Introduction to the principle of the roots vacuum pump structure

2025-5-26