Introduction to Large particle pneumatic conveying material sealing pump, introduction to Material seal pump function advantages and characteristics

Large particle pneumatic conveying material sealing pumpIt is a new type of pneumatic conveying equipment for powder, which uses the ejector effect of high-speed airflow to convey powder materials.,the main features are Wear is small, Small maintenance, Convenient and flexible layout, Small maintenance and Wear is small,has been favored by more and more customers.。The following is to introduce the Large particle pneumatic conveying material sealing pump:

1、Brief introduction of Large particle pneumatic conveying material sealing pump

Large particle pneumatic conveying material sealing pumpIt is a new type of powder pneumatic conveying equipment, belonging to the category of low-pressure dilute phase conveying.,multifunctional, with functions such as Long-distance or complex terrain material transportation, Waste disposal, System supporting use, Raw material transportation and Dust control,the product looks beautiful.,is a kind of Large particle pneumatic conveying material sealing pump manufactured by hyde。

Large particle pneumatic conveying material sealing pump

2、Introduction of Large particle pneumatic conveying material sealing pump characteristics

Large particle pneumatic conveying material sealing pumpit has the characteristics of easy to operate, be of simple construction, Pollution-free transportation, Simple operation and omniseal,it has the functions of Conveying of powdery materials, Waste disposal, Raw material transportation, Conveying of powdery materials and System supporting use,By adopting the low positive pressure and fully sealed transportation mode, foreign substances can not enter the pipe and will not change the properties of the required materials.、Can be flexibly arranged and configured according to the specific situation of the system.、Powder can be continuously conveyed, and the conveying efficiency is improved. The equipment has the function of automatically adjusting the output, which can adjust the conveying quantity according to the actual demand and achieve good ash conveying effect.、Using low-pressure conveying mode, the pressure of ash conveying medium is low, so the equipment pipes and valves are not easy to wear and prolong the service life.、Compared with the traditional mechanical conveying mode, the pneumatic conveying mode has higher energy efficiency ratio and lower energy consumption. The fully sealed design also reduces dust emission and is beneficial to environmental protection.,it is widely used in food, Thermoelectric industry, building materials, Alumina powder conveying, Aluminum industry and other industries,It is a kind of equipment that uses the ejector effect of high-speed airflow to transport powdery materials.。

Large particle pneumatic conveying material sealing pump

3、Large particle pneumatic conveying material sealing pump use

The purpose of Large particle pneumatic conveying material sealing pump is introduced as follows:

- Powder material conveying

- System integration and customization

- Dust control in environmental protection field

- Waste treatment and reuse

- Long-distance or complex terrain material transportation

The Large particle pneumatic conveying material sealing pump is mainly used for conveying all kinds of dry and loose powder materials, such as fly ash, alumina powder, dry kiln ash, limestone powder, cement powder and so on.

The Large particle pneumatic conveying material sealing pump can also be used as a supporting equipment for large-scale pneumatic conveying system or powder treatment system, and work together with other equipment to realize automatic and continuous powder conveying.

In the field of environmental protection, Large particle pneumatic conveying material sealing pumps play an important role. It can be used to collect and transport dust produced in industrial production process, thus effectively reducing dust pollution and improving working environment. In addition, the fully sealed design of the Large particle pneumatic conveying material sealing pump also prevents the leakage of dust and protects the surrounding environment.

Large particle pneumatic conveying material sealing pumps can also be used in the field of waste treatment, such as conveying fly ash and other wastes for the production of environmentally friendly bricks or other recycling ways.

Large particle pneumatic conveying material sealing pumps are suitable for long-distance or complex terrain material transportation, such as mountains, hills, narrow urban spaces, etc., because they have the characteristics of Reliable operation.

Large particle pneumatic conveying material sealing pump

4、Large particle pneumatic conveying material sealing pump structure composition

The Large particle pneumatic conveying material sealing pump has the following structure

- Feed port and discharge port

- Cylindrical pump body

- sealing device

- Nozzle adjusting device

- injector

The inlet is used to add powder materials into the Large particle pneumatic conveying material sealing pump, and the outlet is responsible for discharging the transported powder materials. The design of inlet and outlet needs to consider the fluidity, sealing and easy cleaning of powder.

The cylindrical pump body is the main part of the Large particle pneumatic conveying material sealing pump, which contains the nozzle and powder materials, and provides the necessary space for air flow and powder to be mixed and transported. The material and structure design of the pump body need to consider the factors such as wear resistance, corrosion resistance and sealing.

The sealing device is an important part in the Large particle pneumatic conveying material sealing pump, which is used to ensure the tightness inside the pump body and prevent the leakage of airflow and powder. The design and manufacture of sealing device need to consider the factors such as wear resistance, corrosion resistance and sealing performance.

The nozzle adjusting device is used to adjust the air outlet volume and air outlet angle of the nozzle to adapt to different conveying requirements and powder characteristics. By adjusting the nozzle adjusting device, the conveying performance of the Large particle pneumatic conveying material sealing pump can be optimized and the conveying efficiency and stability can be improved.

Nozzle is one of the key parts of the Large particle pneumatic conveying material sealing pump, which is responsible for generating high-speed airflow and ejecting powder materials for transportation. The design and manufacturing accuracy of the nozzle have an important influence on the performance of the Large particle pneumatic conveying material sealing pump.

Large particle pneumatic conveying material sealing pump

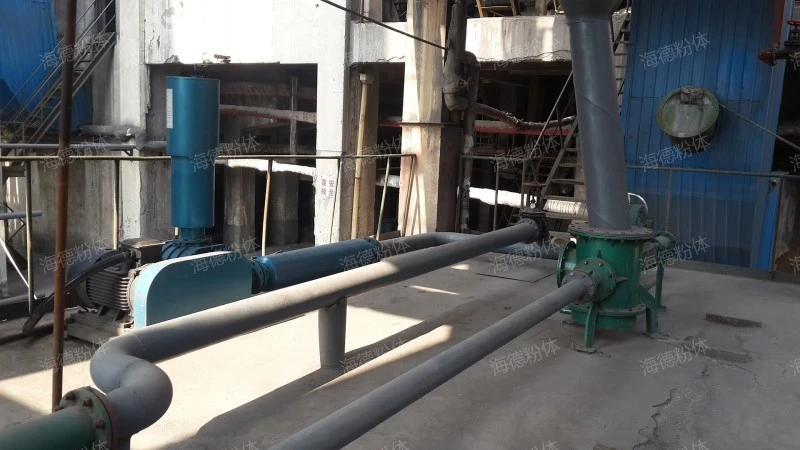

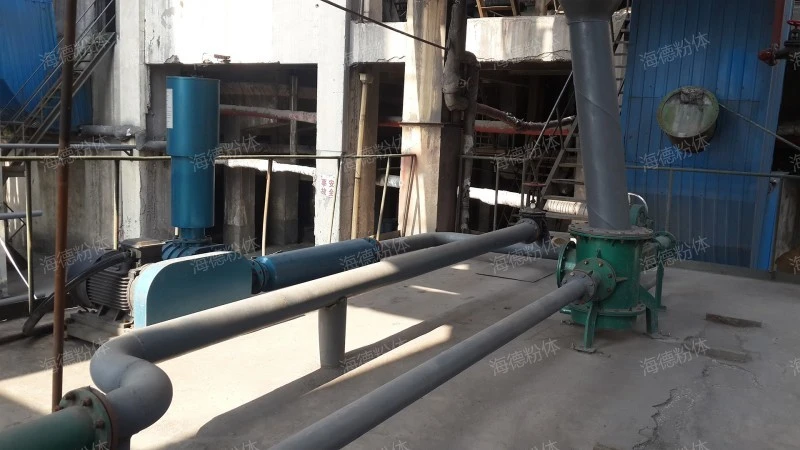

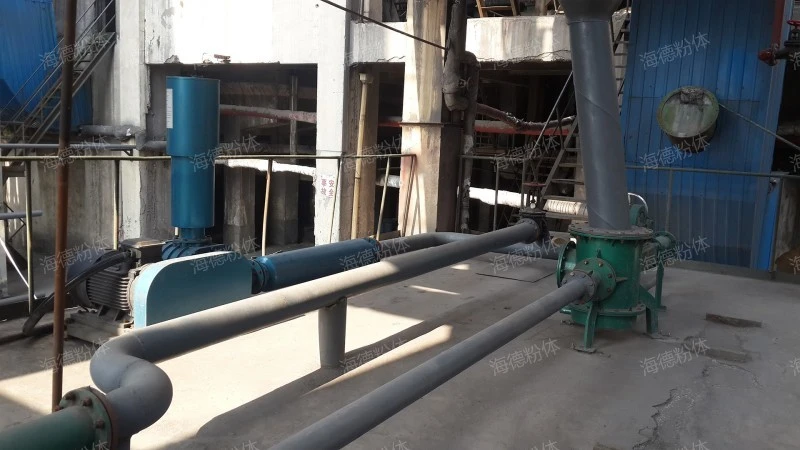

5、Large particle pneumatic conveying material sealing pump field real shot

High-definition pictures of hyde powder Large particle pneumatic conveying material sealing pump, showing different specifications and models.。

Large particle pneumatic conveying material sealing pump

Note: All the pictures in this article were taken by hyde manufacturer.。

6、Large particle pneumatic conveying material sealing pump application

Large particle pneumatic conveying material sealing pumps have the following purposes.

- Supporting industrial production

- Powder material conveying

- Raw material transportation in industrial production

- System supporting use

- Environmental protection and dust control

In medicine such as commodity industry, Large particle pneumatic conveying material sealing pumps can be used to transport all kinds of raw materials and finished products to improve production efficiency.

The Large particle pneumatic conveying material sealing pump is mainly used for conveying all kinds of dry and loose powder materials, such as fly ash, alumina powder, dry kiln ash, limestone powder, cement powder and so on.

In pottery and porcelain such as commodity industry, Large particle pneumatic conveying material sealing pumps are often used as supporting equipment. It can cooperate with other production equipment to realize the automatic and continuous transportation of powder materials. This improves the production efficiency, reduces the labor cost, and helps to realize the automation and intelligence of the production process.

The Large particle pneumatic conveying material sealing pump can also be used as an integrated part of a large pneumatic conveying system or a powder processing system. According to customers' specific needs and scenarios, the Large particle pneumatic conveying material sealing pump can be customized and optimized to achieve a more efficient and reliable powder conveying solution.

In the field of environmental protection, Large particle pneumatic conveying material sealing pumps can be used for dust collection and transportation, which helps to reduce dust pollution and improve the working environment.

Large particle pneumatic conveying material sealing pump

Large particle pneumatic conveying material sealing pumpmultifunctional, with functions such as System supporting use, Long-distance or complex terrain material transportation, Dust control, Raw material transportation and Waste disposal,the advantage is It can be flexibly arranged and configured according to the specific conditions of the system to meet the transportation needs of different projects. Pipes can be arranged horizontally, vertically and obliquely, which is suitable for all kinds of complicated transportation scenes.、It can be transported continuously, and the output of equipment can be automatically adjusted to achieve good ash conveying effect.、The pressure of ash conveying medium is low, the valve of equipment pipeline is not easy to wear, and the service life is long、The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small and the use cost is reduced.、The low positive pressure and fully sealed conveying mode is adopted, which ensures that the powder will not leak to the external environment during the conveying process and meets the environmental protection requirements. The fully sealed design also prevents foreign substances from entering the tube, ensuring the purity and quality of the powder.,the main structure includes injector, Feed port and discharge port, Nozzle adjusting device, Bottom vaporization device, Cylindrical pump body and so on,This productSimple structure and reliable operation.。

Related recommendation

-

What is a Pneumatic conveying of light calcium powder? Material conveying specifications, models, and parameters

2025-5-26 -

Introduction to Automatic metering and conveying and Powder conveying working principle

2025-5-26 -

Introduction to High suction negative pressure conveying and Powder pneumatic conveying working principle

2025-5-26 -

What is a Positive pressure nitrogen circulation transportation? Introduction to the advantages and characteristics of Pneumatic conveying equipment functions

2025-5-26 -

氧化铝气力输送

2014-3-10 -

Introduction to Stainless steel pneumatic ash silo pump, bin pump specifications, model parameters

2025-5-26 -

Introduction to Bulk powder pneumatic conveying system, advantages, characteristics and principles of Pneumatic conveying equipment

2025-5-26 -

What is a Graphite electrode pneumatic conveying? Introduction to the Working Principle of Pneumatic conveying equipment

2025-5-26 -

Introduction to Double stage series Roots blower, how much is the price of the Three leaf Roots blower?

2025-5-26 -

What is a Nitrogen closed loop conveying system? Introduction to the principle of Powder conveying structure

2025-5-26