What is a Low-pressure continuous conveying material sealing pump? Introduction to the advantages and characteristics of Material seal pump functions

Low-pressure continuous conveying material sealing pumpIt is a new type of powder pneumatic conveying equipment, belonging to the category of low-pressure dilute phase conveying.,is a Low-pressure continuous conveying material sealing pump。The following is to introduce the Low-pressure continuous conveying material sealing pump:

1、Brief introduction of Low-pressure continuous conveying material sealing pump

Low-pressure continuous conveying material sealing pumpIt is a device for conveying powdery materials by using the ejector effect of high-speed airflow.。

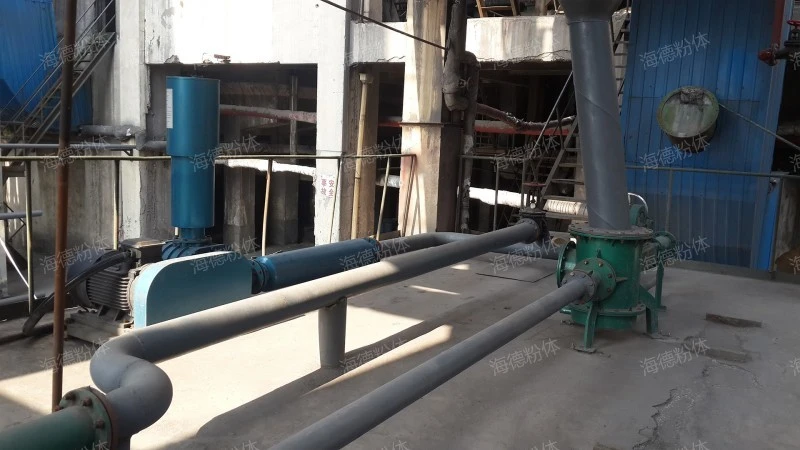

Low-pressure continuous conveying material sealing pump

2、Low-pressure continuous conveying material sealing pump video detail

You can buy Low-pressure continuous conveying material sealing pump according to your needs and show you product videos.。

Low-pressure continuous conveying material sealing pump

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. It has a wide range of uses, and is often used inRaw material transportation,Dust control,Dust control,Long-distance or complex terrain material transportation,System supporting use and so on。

3、Low-pressure continuous conveying material sealing pump application

Low-pressure continuous conveying material sealing pumps have the following purposes.

- System integration and customization

- Powder material conveying

- Dust control in environmental protection field

- Waste disposal

- System supporting use

The Low-pressure continuous conveying material sealing pump can also be used as a supporting equipment for large-scale pneumatic conveying system or powder treatment system, and work together with other equipment to realize automatic and continuous powder conveying.

The Low-pressure continuous conveying material sealing pump is mainly used for conveying all kinds of dry and loose powder materials, such as fly ash, alumina powder, dry kiln ash, limestone powder, cement powder and so on.

In the field of environmental protection, Low-pressure continuous conveying material sealing pumps play an important role. It can be used to collect and transport dust produced in industrial production process, thus effectively reducing dust pollution and improving working environment. In addition, the fully sealed design of the Low-pressure continuous conveying material sealing pump also prevents the leakage of dust and protects the surrounding environment.

Low-pressure continuous conveying material sealing pumps are also widely used in the field of waste treatment. For example, it can transport fly ash and other wastes to designated disposal sites, or be used in recycling ways such as the production of environmentally friendly bricks. This not only helps to reduce the accumulation and pollution of waste, but also realizes the reuse of resources.

The Low-pressure continuous conveying material sealing pump can also be used as an integrated part of a large pneumatic conveying system or a powder processing system. According to customers' specific needs and scenarios, the Low-pressure continuous conveying material sealing pump can be customized and optimized to achieve a more efficient and reliable powder conveying solution.

Low-pressure continuous conveying material sealing pump

4、Low-pressure continuous conveying material sealing pump performance advantage

The advantages of Low-pressure continuous conveying material sealing pump are as follows:

- Low pressure transportation, little wear and tear.

- Strong adaptability and flexible layout

- Simple structure and convenient operation and maintenance.

- regulate automatically

- Continuous conveying

The pressure of ash conveying medium is low, the valve of equipment pipeline is not easy to wear and has long service life.

Pipes can be arranged horizontally, vertically and obliquely to adapt to various complicated transportation scenes.

The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small, and the use cost is reduced.

It can automatically adjust the output to achieve good ash conveying effect.

Powder can be continuously conveyed, and the conveying efficiency is improved. The equipment has the function of automatically adjusting the output, which can adjust the conveying capacity according to the actual demand and achieve good ash conveying effect.

Low-pressure continuous conveying material sealing pump

5、Working principle of Low-pressure continuous conveying material sealing pump

Low-pressure continuous conveying material sealing pumpin the course of work,Using the action of air jet, the air drives the ash particles to send the ash to ash storage. There are two main sources of energy, one is the kinetic energy of the fan, and the other is the potential energy of the material column. When the material column is high, the potential energy is high and the pressure is high, the conveying capacity is correspondingly large, and vice versa.,features include easy to operate, Long service life, Transport stability, Reliable operation and be of simple construction,is a popular Low-pressure continuous conveying material sealing pump,It can be used for Waste disposal, Raw material transportation, Conveying of powdery materials, Dust control, System supporting use, Long-distance or complex terrain material transportation and so on,The price is low and affordable。

Low-pressure continuous conveying material sealing pump

6、Brief introduction of hyde

hyde is a professional and large-scale Low-pressure continuous conveying material sealing pump manufacturer, which has many years of production and operation, complete production facilities, skilled staff and high production capacity and product quality. It is a Low-pressure continuous conveying material sealing pump manufacturer trusted by consumers at present.。

hyde powder

Low-pressure continuous conveying material sealing pumpit is widely used in Cement industry, electricity industry, environmental protection, Thermoelectric industry and glass,Small maintenance,Transport stability,Can be continuously conveyed.,Pollution-free transportation,omniseal,The pressure of ash conveying medium is low, the valve of equipment pipeline is not easy to wear, and the service life is long、By adopting the low positive pressure and fully sealed transportation mode, foreign substances can not enter the pipe and will not change the properties of the required materials.、Powder can be continuously conveyed, and the conveying efficiency is improved. The equipment has the function of automatically adjusting the output, which can adjust the conveying quantity according to the actual demand and achieve good ash conveying effect.、The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small and the use cost is reduced.、Can be flexibly arranged and configured according to the specific situation of the system.。

Related recommendation

-

What is a Foam powder conveying? How much is the price of the Material conveying?

2025-5-26 -

Introduction to Carbon steel ash tank pump, introduction to AV pump advantages and characteristics

2025-5-26 -

What is a Pearl sand pneumatic conveying equipment? Material conveying specifications, models, and parameters

2025-5-26 -

Introduction to Vehicle mounted mobile conveyor, introduction to Powder pneumatic conveying advantages and characteristics

2025-5-26 -

What is a Upward discharge pneumatic conveying bin pump? bin pump specifications, models, and parameters

2025-5-26 -

Introduction to Nano calcium carbonate conveying equipment, introduction to Powder pneumatic conveying advantages and characteristics

2025-5-26 -

What is a Grain granule conveying system? How much is the price of the pneumatic conveying system?

2025-5-26 -

What is a Dry pebble pneumatic conveying? Introduction to the Working Principle of Powder conveying

2025-5-26 -

What is a Soybean grain pneumatic conveying? pneumatic conveying specifications, models, and parameters

2025-5-26 -

Introduction to Measuring and mixing conveying equipment, introduction to Pneumatic conveying equipment advantages and characteristics

2025-5-26