What is a Dust-free sealed pump? Material seal pump specifications, models, and parameters

Dust-free sealed pumpIt is a kind of equipment that uses the ejector effect of high-speed airflow to transport powdery materials.,is a common Dust-free sealed pump,is a popular Dust-free sealed pump。

1、Brief introduction of Dust-free sealed pump

Dust-free sealed pumpIt is a device for conveying powdery materials by using the ejector effect of high-speed airflow.,it is widely used in glass, pottery and porcelain, environmental protection, Aluminum industry and Processing industry,the product looks beautiful.,Mainly used forConveying of powdery materials,Raw material transportation,Long-distance or complex terrain material transportation,Dust control andWaste disposal,it has the functions of Dust control, System supporting use, Conveying of powdery materials, Dust control and Raw material transportation。

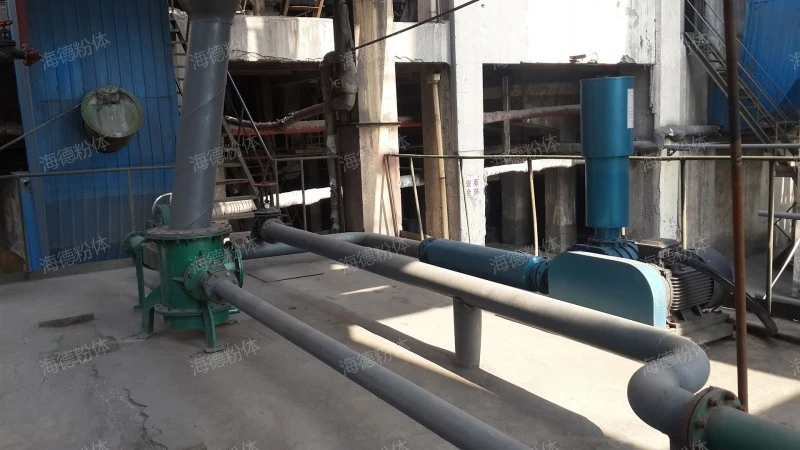

Dust-free sealed pump

2、Dust-free sealed pump characteristics

Dust-free sealed pumpit has the characteristics of easy to operate, Reliable operation, omniseal, be of simple construction and Transport stability,is a kind of high quality and low price Dust-free sealed pump,the principle is simple.Using the high-speed airflow generated by the nozzle, a negative pressure area is formed, thereby ejecting powder materials into the pump body. This ejector action enables the powder material to be carried by the airflow and transported.,the product looks beautiful.,is carefully developed by hyde powder combined with advanced technology。

Dust-free sealed pump

3、Advantages of Dust-free sealed pump principle

Dust-free sealed pumpBased on the ejector effect of high-speed airflow, the mixing and acceleration of airflow and powder, the formation of material column and pressure balance, the isolation and sealing of positive and negative pressure, and the automatic adjustment and adaptation.,the advantage is The design is relatively simple, and there are no complicated mechanical structures and vulnerable parts, so it is very convenient to operate. The maintenance amount is small and the use cost is reduced.、Using low-pressure conveying mode, the pressure of ash conveying medium is low, so the equipment pipes and valves are not easy to wear and prolong the service life.、Powder can be continuously conveyed, and the conveying efficiency is improved. The equipment has the function of automatically adjusting the output, which can adjust the conveying quantity according to the actual demand and achieve good ash conveying effect.、Can be flexibly arranged and configured according to the specific situation of the system.、Compared with the traditional mechanical conveying mode, the pneumatic conveying mode has higher energy efficiency ratio and lower energy consumption. The fully sealed design also reduces dust emission and is beneficial to environmental protection.,It has the functions of System supporting use, Long-distance or complex terrain material transportation, Conveying of powdery materials, Raw material transportation and Waste disposal,is a kind of high quality and low price Dust-free sealed pump,the main structure includes Nozzle adjusting device, Supporting and connecting parts, Cylindrical pump body, injector, Nozzle adjusting device and so on,This productThe overall structural design is relatively simple and compact.。

Dust-free sealed pump

4、Dust-free sealed pump function

Dust-free sealed pumpmultifunctional, with functions such as System supporting use, Long-distance or complex terrain material transportation, Waste disposal, Conveying of powdery materials and System supporting use。

Dust-free sealed pump

5、Structural advantages of Dust-free sealed pump

The Dust-free sealed pump has the following structure

- sealing device

- Bottom vaporization device

- Nozzle adjusting device

- Feed port and discharge port

- Bottom vaporization device

The sealing device is an important part in the Dust-free sealed pump, which is used to ensure the tightness inside the pump body and prevent the leakage of airflow and powder. The design and manufacture of sealing device need to consider the factors such as wear resistance, corrosion resistance and sealing performance.

The bottom vaporizing device is an optional component in the Dust-free sealed pump. It vaporizes the powder at the bottom of the pump body by steam or other vaporizing media to reduce the friction and wear between the powder and the pump body and improve the smoothness and efficiency of transportation.

The nozzle adjusting device is used to adjust the air outlet volume and air outlet angle of the nozzle to adapt to different conveying requirements and powder characteristics. By adjusting the nozzle adjusting device, the conveying performance of the Dust-free sealed pump can be optimized and the conveying efficiency and stability can be improved.

The inlet is used to add powder materials into the Dust-free sealed pump, and the outlet is responsible for discharging the transported powder materials. The design of inlet and outlet needs to consider the fluidity, sealing and easy cleaning of powder.

The bottom vaporizing device is an optional component in the Dust-free sealed pump. It vaporizes the powder at the bottom of the pump body by steam or other vaporizing media to reduce the friction and wear between the powder and the pump body and improve the smoothness and efficiency of transportation.

Dust-free sealed pump

6、Dust-free sealed pump structure

The Dust-free sealed pump structure is introduced as follows:

- Supporting and connecting parts

- injector

- sealing device

- Cylindrical pump body

- Nozzle adjusting device

The supporting and connecting parts are used to support and connect various parts of the Dust-free sealed pump to ensure the stability and integrity of the pump body. The design and manufacture of these components need to consider factors such as strength, stiffness and stability.

Nozzle is one of the key parts of the Dust-free sealed pump, which is responsible for generating high-speed airflow and ejecting powder materials for transportation. The design and manufacturing accuracy of the nozzle have an important influence on the performance of the Dust-free sealed pump.

The sealing device is an important part in the Dust-free sealed pump, which is used to ensure the tightness inside the pump body and prevent the leakage of airflow and powder. The design and manufacture of sealing device need to consider the factors such as wear resistance, corrosion resistance and sealing performance.

The cylindrical pump body is the main part of the Dust-free sealed pump, which contains the nozzle and powder materials, and provides the necessary space for air flow and powder to be mixed and transported. The material and structure design of the pump body need to consider the factors such as wear resistance, corrosion resistance and sealing.

The nozzle adjusting device is used to adjust the air outlet volume and air outlet angle of the nozzle to adapt to different conveying requirements and powder characteristics. By adjusting the nozzle adjusting device, the conveying performance of the Dust-free sealed pump can be optimized and the conveying efficiency and stability can be improved.

Dust-free sealed pump

Dust-free sealed pumpSimple operation,Reliable operation,Wear is small,omniseal,Long service life,it has the functions of Conveying of powdery materials, Long-distance or complex terrain material transportation, Raw material transportation, Waste disposal and Dust control。

Related recommendation

-

What is a Iron oxide powder pneumatic conveying equipment? How much is the price of the pneumatic conveying system?

2025-5-26 -

What is a Return coke powder conveying system? Introduction to the Working Principle of Pneumatic conveying equipment

2025-5-26 -

Introduction to Peanut conveying equipment, advantages, characteristics and principles of Pneumatic conveying equipment

2025-5-26 -

Introduction to Dry stone powder conveying equipment, introduction to pneumatic conveying function advantages and characteristics

2025-5-26 -

Introduction to Smelting plant transportation and Pneumatic conveying equipment structure principle

2025-5-26 -

Introduction to Peanut pneumatic conveying, pneumatic conveying system advantages, characteristics and principles

2025-5-26 -

Introduction to Slag conveying and Pneumatic conveying equipment structure principle

2025-5-26 -

Introduction to Secondary zinc oxide pneumatic conveying system, how much is the price of the pneumatic conveying?

2025-5-26 -

What is a Weighing and batching pneumatic conveying? pneumatic conveying specifications, models, and parameters

2025-5-26 -

Introduction to Fine coal powder conveying equipment, advantages, characteristics and principles of Powder conveying

2025-5-26