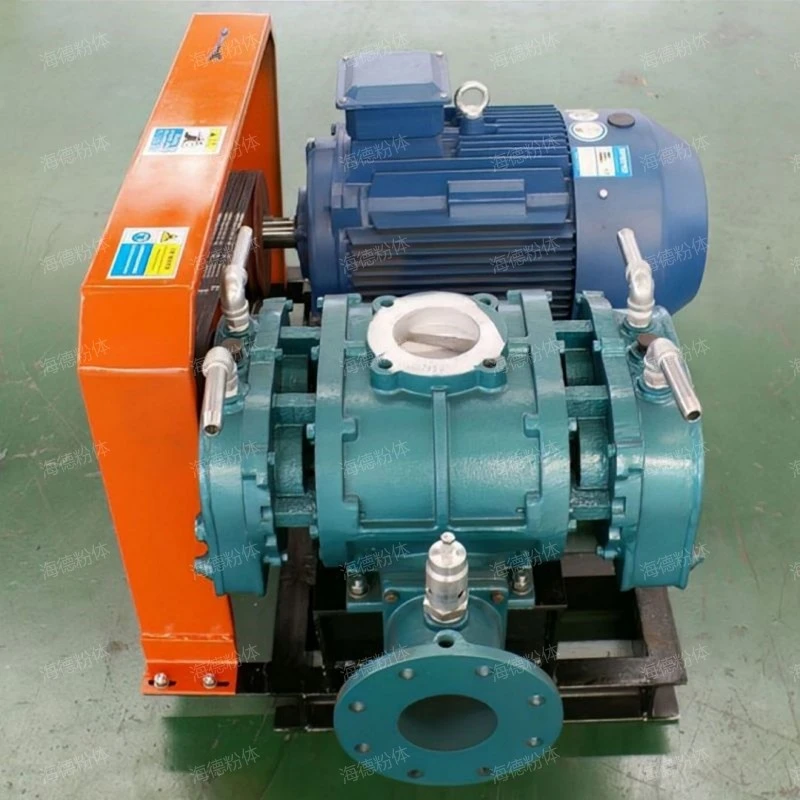

Introduction to Oil-free anticorrosive Roots vacuum pump, the roots vacuum pump advantages, characteristics and principles

Oil-free anticorrosive Roots vacuum pumpis a vacuum pump that sucks air through a pair of rotors making relative rotary motion in the pump cavity.。

1、Brief introduction of Oil-free anticorrosive Roots vacuum pump

Oil-free anticorrosive Roots vacuum pumpis an efficient and reliable vacuum equipment.,is a Oil-free anticorrosive Roots vacuum pump,the principle is simple.based on the relative motion between the rotors, the gas is sucked from the air inlet through the rotation of the rotors, compressed in the pump cavity, and finally discharged through the air outlet, thus forming a vacuum in the pump cavity.,usually used in sewage disposal, power, Food and beverage processing, aquaculture, aquaculture and other fields,was developed and designed by hyde。

Oil-free anticorrosive Roots vacuum pump

2、Oil-free anticorrosive Roots vacuum pump advantage

The advantages of Oil-free anticorrosive Roots vacuum pump are as follows:

- reliability

- be of simple construction

- High exhaust speed

- high-effect

- Wide application range

Because there is no liquid and oil film, the Oil-free anticorrosive Roots vacuum pump will not have oil leakage and other problems, with longer service life and lower maintenance cost.

The structure of the Oil-free anticorrosive Roots vacuum pump is relatively simple, mainly composed of pump body and other parts.

The Oil-free anticorrosive Roots vacuum pump has a large exhaust speed, which can quickly exhaust gas from the pump cavity, forming a high vacuum degree.

The Oil-free anticorrosive Roots vacuum pump has very high pumping speed and exhaust capacity, especially in the range of high vacuum, and its performance is particularly outstanding.

Oil-free anticorrosive Roots vacuum pumps are suitable for many industries, such as building materials and other fields, and are used in various technological processes such as vacuum distillation, drying, purification, pumping and vacuum packaging.

Oil-free anticorrosive Roots vacuum pump

3、Oil-free anticorrosive Roots vacuum pump structure composition

The Oil-free anticorrosive Roots vacuum pump structure is introduced as follows:

- sealing device

- pump body

- gearing

- rotator

- bearing

The sealing device is used to ensure that the gas in the pump cavity will not leak to the external environment.

Pump body is usually made of cast iron or cast steel, which has good strength and sealing performance.

The transmission device is usually driven by motor or reducer, which makes the rotor rotate relatively in the pump cavity.

Rotor is the core component of the Oil-free anticorrosive Roots vacuum pump, and its profile design and machining accuracy directly affect the performance and service life of the pump.

Bearings are responsible for supporting the rotary motion of the rotor, and high-precision bearings are usually used to ensure the stable operation of the rotor.

Oil-free anticorrosive Roots vacuum pump

4、Oil-free anticorrosive Roots vacuum pump use

Oil-free anticorrosive Roots vacuum pumpWidely used in Gas treatment, vacuum distillation, vacuum treatment, Vacuum extraction and vacuum packaging,multifunctional, with functions such as dehydrate, material handling, aquaculture, Pressurized transportation and sewage disposal,be loved by our customers.。

Oil-free anticorrosive Roots vacuum pump

5、Advantages of Oil-free anticorrosive Roots vacuum pump principle

Oil-free anticorrosive Roots vacuum pumpmainly based on the relative rotational movement of the rotor in the pump chamber. There are two rotors in the pump, and a certain gap is kept between them and the inner wall of the pump shell. Through the rotation of the rotor, the gas is sucked in from the air inlet, and then discharged from the air outlet through the processes of compression and exhaust. Due to the special design of the rotor profile, the gas in the pump cavity is effectively compressed and discharged, thus achieving vacuum extraction.。

Oil-free anticorrosive Roots vacuum pump

Oil-free anticorrosive Roots vacuum pumpthe product looks beautiful.,at the start of the operation,the suction, compression and exhaust processes are completed by synchronous high-speed rotation of two or more trilobal rotors in the pump cavity. The rotor consists of three blades, whose shapes and positions are symmetrical. When the motor is started, the two rotors start to rotate. Due to the symmetry of the design and position of the blades, air enters the pump body from the air inlet, and is gradually squeezed and discharged by the blades, forming a vacuum.。

Related recommendation

-

Introduction to Petrochemical Lu's blower, Roots Blower advantages, characteristics and principles

2025-5-26 -

What is a Pneumatic conveying of asbestos powder? How much is the price of the pneumatic conveying?

2025-5-26 -

Introduction to Stone gas power conveying system and Material conveying advantages and features

2025-5-26 -

What is a Nitrogen protection transportation? Introduction to the principle of Pneumatic conveying equipment structure

2025-5-26 -

Introduction to Pneumatic conveying equipment for sintering dust removal ash, pneumatic conveying specifications, model parameters

2025-5-26 -

What is a Sodium hypochlorite pneumatic conveying equipment? Introduction to the Working Principle of Pneumatic conveying equipment

2025-5-26 -

Introduction to HDSR200V roots vacuum pump and the roots vacuum pump advantages and features

2025-5-26 -

What is a Electric variable frequency discharger? unloader specifications, models, and parameters

2025-5-26 -

What is a Roots blower for food industry? Introduction to the advantages and characteristics of blower functions

2025-5-26 -

Introduction to Manganese silicate conveying equipment and Powder conveying working principle

2025-5-26