Introduction to Oil free anti-corrosion Roots vacuum pump unit, blower advantages, characteristics and principles

Oil free anti-corrosion Roots vacuum pump unitis an efficient volumetric gas conveying and pressurizing equipment.,it is an ideal choice for customers to buy Oil free anti-corrosion Roots vacuum pump unit。The following is to introduce the Oil free anti-corrosion Roots vacuum pump unit:

1、Brief introduction of Oil free anti-corrosion Roots vacuum pump unit

Oil free anti-corrosion Roots vacuum pump unita rotary compressor that uses two lobed rotors to move relative to each other in a cylinder to compress and transport gas.,the product looks atmospheric.,it has the functions of pick up the suction, material fluidization, aeration, sewage disposal and cool,it can be used in Food and beverage processing, power, water treatment, mine, petrify and other industries,at the start of the operation,The two three-blade impellers rotate relatively in the space sealed by the casing and the wallboard. Each impeller adopts the envelope of involute or epicycloid, the three blades of each impeller are exactly the same, and the two impellers are also exactly the same, which greatly reduces the machining difficulty. During the rotation of the impeller, air enters the air inlet cavity under the action of atmospheric pressure, and then two blades of each impeller, the wallboard and the casing form a sealed cavity. During the rotation of the impeller, the air in the air inlet cavity is continuously brought to the exhaust cavity by the sealed cavity formed by the two blades, and because the impellers in the exhaust cavity are meshed with each other, the air between the two blades is squeezed out, so that the air is continuously transported from the air inlet to the air outlet.。

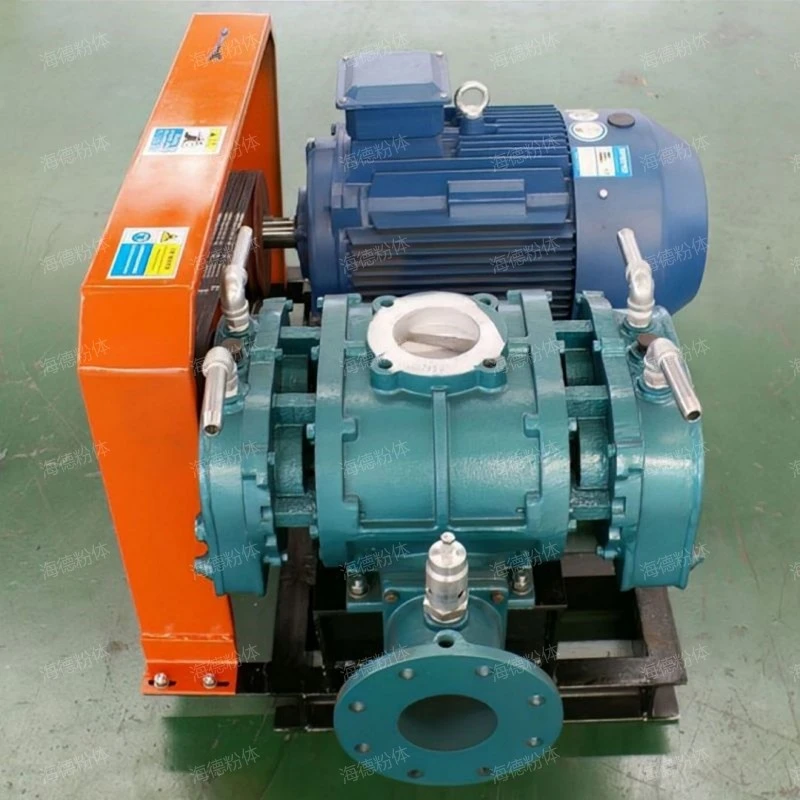

Oil free anti-corrosion Roots vacuum pump unit

2、Oil free anti-corrosion Roots vacuum pump unit application

Oil free anti-corrosion Roots vacuum pump unitIt can be used for exhaust emission, aquaculture, dehydrate, cool, Pressurized transportation, pick up the suction and so on,generally, it is composed of bearing, impeller, bearing, fuel tank, rotator and other major components,at runtime,When the motor drives one impeller to rotate, the other impeller will rotate synchronously at the same speed and in the opposite direction under the action of the synchronous gear. In the process of rotation, because the gaps between impeller and impeller, impeller and casing, impeller and wallboard are very small, a vacuum state is formed at the air inlet, and air is sucked into the air inlet cavity under the action of atmospheric pressure. As the impeller continues to rotate, two blades of each impeller, the wallboard and the casing form a sealed cavity, and the air in the air inlet cavity is continuously brought to the exhaust cavity by the sealed cavity formed by the two blades. Because the impellers in the exhaust cavity are meshed with each other, the air between the two blades is squeezed out. After continuous inhalation and extrusion, air is continuously transported from the air inlet to the air outlet, completing the whole gas transportation process.。

Oil free anti-corrosion Roots vacuum pump unit

3、Oil free anti-corrosion Roots vacuum pump unit explanation video

You can buy Oil free anti-corrosion Roots vacuum pump unit according to your needs and show you product videos.。

Oil free anti-corrosion Roots vacuum pump unit

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. multifunctional, with functions such as dry, desulfurization oxidation, mix, aquaculture and ventilation。

4、Introduction of Oil free anti-corrosion Roots vacuum pump unit characteristics

Oil free anti-corrosion Roots vacuum pump unitit has the characteristics of convenient maintenance, Precise control, energy-efficient, durable performance and low noise,it has the functions of exhaust emission, dry, desulfurization oxidation, dehydrate and supply air。

Oil free anti-corrosion Roots vacuum pump unit

5、Working principle of Oil free anti-corrosion Roots vacuum pump unit

Oil free anti-corrosion Roots vacuum pump unitat the start of the operation,The two three-blade impellers rotate relatively in the space sealed by the casing and the wallboard. Each impeller adopts the envelope of involute or epicycloid, the three blades of each impeller are exactly the same, and the two impellers are also exactly the same, which greatly reduces the machining difficulty. During the rotation of the impeller, air enters the air inlet cavity under the action of atmospheric pressure, and then two blades of each impeller, the wallboard and the casing form a sealed cavity. During the rotation of the impeller, the air in the air inlet cavity is continuously brought to the exhaust cavity by the sealed cavity formed by the two blades, and because the impellers in the exhaust cavity are meshed with each other, the air between the two blades is squeezed out, so that the air is continuously transported from the air inlet to the air outlet.。

Oil free anti-corrosion Roots vacuum pump unit

6、Functional advantages of Oil free anti-corrosion Roots vacuum pump unit

Oil free anti-corrosion Roots vacuum pump units have the following advantages.

- Economical and durable

- Convenient maintenance

- Durable performance

- Compact structure and small floor space.

- Run smoothly

The design without lubrication reduces the maintenance cost and improves the economy of the equipment.

The structure of the Oil free anti-corrosion Roots vacuum pump unit is relatively simple and easy to maintain.

Impeller and shaft are integrated structure, and the impeller is not worn, so the performance of the fan is durable and can run continuously for a long time.

The Oil free anti-corrosion Roots vacuum pump unit is simple in design and easy to manufacture and maintain.

The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the Oil free anti-corrosion Roots vacuum pump unit less vibration and noise.

Oil free anti-corrosion Roots vacuum pump unit

Oil free anti-corrosion Roots vacuum pump unitthe advantage is Due to the adoption of synchronous gear transmission and small gap design, the Oil free anti-corrosion Roots vacuum pump unit runs stably and reliably, without contact and wear parts, and has a long service life.、The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the fan have small vibration and low noise.、Simple structural design, stable and reliable operation and convenient maintenance. This enables it to maintain high working efficiency and stability in long-term operation.、Because of the design of three-blade rotor, the Oil free anti-corrosion Roots vacuum pump unit has little vibration and low noise during operation, and the operation is stable and reliable、The air volume is directly proportional to the rotating speed, so its air output is very stable and basically unaffected by pressure changes. This characteristic makes the Oil free anti-corrosion Roots vacuum pump unit perform well in many situations where stable airflow is needed.,The structural design is more advanced and reasonable.,it is mainly composed of wallboard, impeller, fuel tank, muffler and rotator,the product looks beautiful.。

Related recommendation

-

What is a Ore sand conveying system? Introduction to the advantages and characteristics of Powder pneumatic conveying functions

2025-5-26 -

Introduction to Long distance pneumatic conveying of ton bags and pneumatic conveying advantages and features

2025-5-26 -

What is a Lithium fluoride pneumatic conveying system? Introduction to the advantages, characteristics, and principles of the pneumatic conveying system

2025-5-26 -

Introduction to Rare earth powder transportation, introduction to pneumatic conveying system function advantages and characteristics

2025-5-26 -

Introduction to Three leaf Roots blower for the food industry, advantages, characteristics and principles of Roots Blower

2025-5-26 -

What is a Pneumatic conveying of clay powder? Introduction to the advantages and characteristics of the Powder conveying

2025-5-26 -

Introduction to Intelligent weighing and conveying equipment and Pneumatic conveying equipment structure principle

2025-5-26 -

Introduction to Fluorite transportation and Powder conveying structure principle

2025-5-26 -

Introduction to Fluorostone conveying equipment, advantages, characteristics and principles of Powder pneumatic conveying

2025-5-26 -

What is a Lu's blower in the textile industry? blower specifications, models, and parameters

2025-5-26