Introduction to Three leaf Roots blower for material conveying and Roots Blower structure principle

Three leaf Roots blower for material conveyingis a double impeller synchronous compression machine, belonging to a positive displacement blower.。

1、Brief introduction of Three leaf Roots blower for material conveying

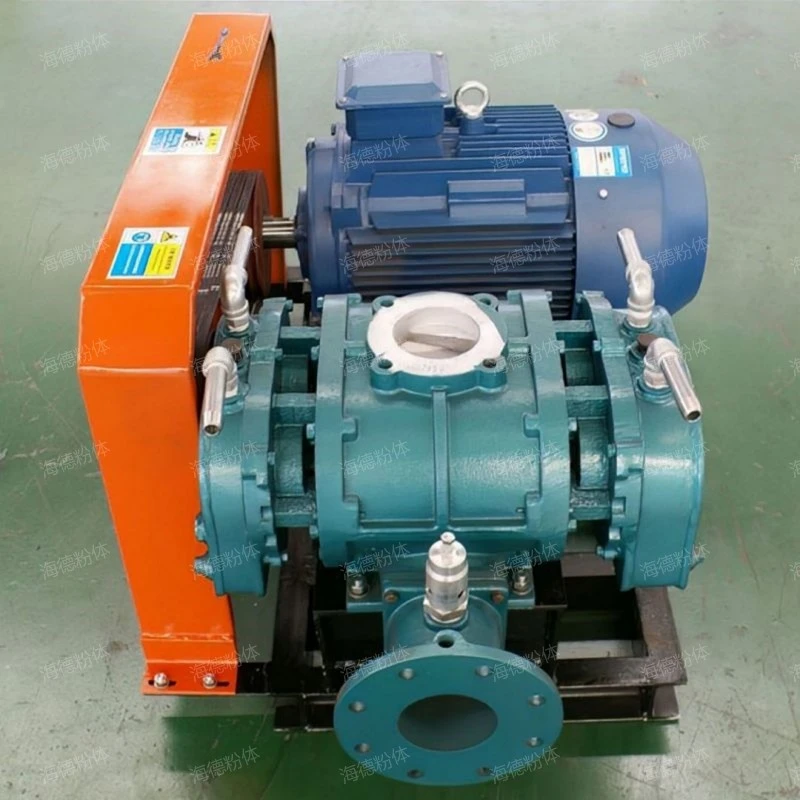

Three leaf Roots blower for material conveyingis a positive displacement blower.,the product looks atmospheric.,is designed by hyde with advanced technology。

Three leaf Roots blower for material conveying

2、Introduction of advantages of Three leaf Roots blower for material conveying

Three leaf Roots blower for material conveyings have the following advantages.

- Durable performance

- Stable and reliable

- Convenient maintenance

- Economical and durable

- Strong adaptability

Impeller and shaft are integrated structure, and the impeller is not worn, so the performance of the fan is durable and can run continuously for a long time.

The Three leaf Roots blower for material conveying has simple structural design, stable and reliable operation and convenient maintenance. This enables it to maintain high working efficiency and stability in long-term operation.

The structure of the Three leaf Roots blower for material conveying is relatively simple and easy to maintain.

The design without lubrication reduces the maintenance cost and improves the economy of the equipment.

The Three leaf Roots blower for material conveying is suitable for conveying and pressurizing a variety of gases, including air, oxygen, nitrogen, etc., and can work stably under different pressures and flows.

Three leaf Roots blower for material conveying

3、Working principle of Three leaf Roots blower for material conveying

Three leaf Roots blower for material conveyingThe two three-blade impellers rotate relatively in the space sealed by the casing and the wallboard. Each impeller adopts the envelope of involute or epicycloid, the three blades of each impeller are exactly the same, and the two impellers are also exactly the same, which greatly reduces the machining difficulty. During the rotation of the impeller, air enters the air inlet cavity under the action of atmospheric pressure, and then two blades of each impeller, the wallboard and the casing form a sealed cavity. During the rotation of the impeller, the air in the air inlet cavity is continuously brought to the exhaust cavity by the sealed cavity formed by the two blades, and because the impellers in the exhaust cavity are meshed with each other, the air between the two blades is squeezed out, so that the air is continuously transported from the air inlet to the air outlet.,can be customized according to user's needs.。

Three leaf Roots blower for material conveying

4、Three leaf Roots blower for material conveying advantage

The advantages of Three leaf Roots blower for material conveying are as follows:

- Compact structure and small floor space.

- Low noise

- energy-efficient

- Run smoothly

- Strong adaptability

The Three leaf Roots blower for material conveying is small in size and occupies a small area, which makes it easy to arrange and install in places with limited space.

The design of the three-blade rotor effectively controls the noise and vibration of the fan.

The Three leaf Roots blower for material conveying has high efficiency and can realize gas transportation and pressurization with low energy consumption.

Due to the design of three-blade rotor, the Three leaf Roots blower for material conveying has little vibration and low noise during operation, and the operation is stable and reliable.

Three leaf Roots blower for material conveyings are suitable for many purposes and have been widely used in various fields.

Three leaf Roots blower for material conveying

5、Three leaf Roots blower for material conveying function

Three leaf Roots blower for material conveyingmultifunctional, with functions such as pressurized transportation, material handling, supply air, ventilation and desulfurization oxidation,at the start of the operation,Gas is compressed and transported based on the relative motion of two lobed rotors in the cylinder. When the two rotors rotate, the volume between them changes constantly, thus realizing the suction, compression and discharge of gas.,the product looks beautiful.,super quality and competitive price。

Three leaf Roots blower for material conveying

6、Three leaf Roots blower for material conveying introduction video

You can buy Three leaf Roots blower for material conveying according to your needs and show you product videos.。

Three leaf Roots blower for material conveying

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. Simple structure and advanced technology.,generally, it is composed of bearing, fuel tank, case, impeller, muffler and other major components。

Three leaf Roots blower for material conveyingthe advantage is The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the fan have small vibration and low noise.、The air volume is directly proportional to the rotating speed, so its air output is very stable and basically unaffected by pressure changes. This characteristic makes the Three leaf Roots blower for material conveying perform well in many situations where stable airflow is needed.、In the process of air intake and exhaust, the Three leaf Roots blower for material conveying will not produce air pulsation, which means that it does not need an additional buffer gas tank to output gas smoothly. This is particularly important for processes that require stable airflow.、Simple structural design, stable and reliable operation and convenient maintenance. This enables it to maintain high working efficiency and stability in long-term operation.、Due to the adoption of synchronous gear transmission and small gap design, the Three leaf Roots blower for material conveying runs stably and reliably, without contact and wear parts, and has a long service life.,it has the functions of material handling, material fluidization, dry, aeration and desulfurization oxidation。

Related recommendation

-

What is a Corn flour pneumatic conveying? Introduction to the principle of Pneumatic conveying equipment structure

2025-5-26 -

Introduction to Magnesia sand conveying system and Powder conveying structure principle

2025-5-26 -

What is a Pneumatic conveying of organic fertilizer granules? Introduction to the advantages and characteristics of the Powder pneumatic conveying

2025-5-26 -

Introduction to Rubber Conveyor and Powder pneumatic conveying working principle

2025-5-26 -

What is a Aluminum oxide powder conveying? How much is the price of the pneumatic conveying system?

2025-5-26 -

Introduction to Pulse material plug pneumatic conveying equipment, introduction to Pneumatic conveying equipment advantages and characteristics

2025-5-26 -

What is a Stainless steel food grade conveyor? Introduction to the Working Principle of Powder conveying

2025-5-26 -

What is a Calcination ash conveying? Introduction to the Working Principle of Powder pneumatic conveying

2025-5-26 -

Introduction to Yunyingshi pneumatic conveying equipment and Pneumatic conveying equipment working principle

2025-5-26 -

Introduction to PVC powder conveying system, how much is the price of the pneumatic conveying?

2025-5-26