What is a Roots blower in printing and dyeing factory? Introduction to the advantages, characteristics, and principles of the Three leaf Roots blower

Roots blower in printing and dyeing factoryis a device that generates positive pressure or negative pressure through the relative rotation of two impellers, thus compressing and conveying gas.。The following is to introduce the Roots blower in printing and dyeing factory:

1、Brief introduction of Roots blower in printing and dyeing factory

Roots blower in printing and dyeing factoryis a double impeller synchronous compression machine, belonging to a positive displacement blower.,generally, it is composed of muffler, case, muffler, wallboard, bearing and other major components,it is widely used in aquaculture, pneumatic transport, Pharmaceutical and chemical industries, sewage disposal and water treatment,Mainly used forVentilation,aquaculture,dry,supply air andmaterial handling,customizable。

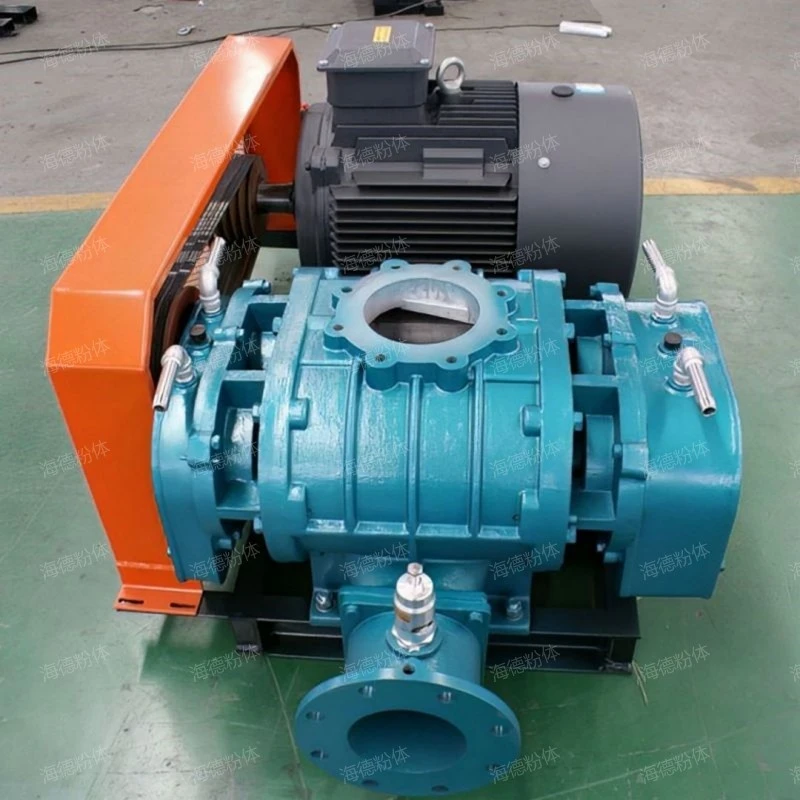

Roots blower in printing and dyeing factory

2、Roots blower in printing and dyeing factory structure composition

The Roots blower in printing and dyeing factory structure is introduced as follows:

- case

- bearing

- muffler

- rotator

- rotator

It mainly plays the role of supporting (wallboard, impeller, muffler) and fixing. The casing is the external structure of the Roots blower in printing and dyeing factory, which is used to support and fix the rotor, bearings and other components, while ensuring the gas tightness.

It is used to support the rotation of the rotor and bear the weight of the rotor and the load during operation.

Used to reduce the noise caused by airflow pulsation when the Roots blower in printing and dyeing factory enters and exits.

The core components are two identical lobed rotors, which usually adopt involute or epicycloid envelope design to ensure close cooperation during rotation and reduce leakage.

The core components are two identical lobed rotors, which usually adopt involute or epicycloid envelope design to ensure close cooperation during rotation and reduce leakage.

Roots blower in printing and dyeing factory

3、Roots blower in printing and dyeing factory characteristics

Roots blower in printing and dyeing factorythe main features are convenient maintenance, durable performance, smooth operation, wide application range and low noise。

Roots blower in printing and dyeing factory

4、Roots blower in printing and dyeing factory introduction video

The following is the live video of Roots blower in printing and dyeing factory designed and produced by hyde powder for users, from which we can see the Due to the adoption of synchronous gear transmission and small gap design, the Roots blower in printing and dyeing factory runs stably and reliably, without contact and wear parts, and has a long service life.、It has high efficiency and can realize gas transportation and pressurization with low energy consumption.、Small size and small floor space make it easy to arrange and install in places with limited space.、The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the Roots blower in printing and dyeing factory less vibration and noise.、Because of the design of three-blade rotor, the Roots blower in printing and dyeing factory has little vibration and low noise during operation, and the operation is stable and reliable of hydeRoots blower in printing and dyeing factory.。

Roots blower in printing and dyeing factory

As you can see from the live video.,Shandong Haide Fenti Engineering Co., Ltd. the advantage is Small size and small floor space make it easy to arrange and install in places with limited space.、Due to the adoption of synchronous gear transmission and small gap design, the Roots blower in printing and dyeing factory runs stably and reliably, without contact and wear parts, and has a long service life.、In the process of air intake and exhaust, the Roots blower in printing and dyeing factory will not produce air pulsation, which means that it does not need an additional buffer gas tank to output gas smoothly. This is particularly important for processes that require stable airflow.、The air volume is directly proportional to the rotating speed, so its air output is very stable and basically unaffected by pressure changes. This characteristic makes the Roots blower in printing and dyeing factory perform well in many situations where stable airflow is needed.、Because of the design of three-blade rotor, the Roots blower in printing and dyeing factory has little vibration and low noise during operation, and the operation is stable and reliable。

5、How much is the Roots blower in printing and dyeing factory?

The Roots blower in printing and dyeing factory price is introduced as follows:

- regional difference

- technology content

- Product configuration difference

- cost of production

- market demand

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

The difference in Roots blower in printing and dyeing factory configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

If the cost of the product is high, the selling price of the product will be high, so the cost input is an important factor that causes the price change of the Roots blower in printing and dyeing factory.

Market change is one of the factors that affect the price range greatly. Market change is unstable, but there are certain rules to follow. Market change is caused by other factors, such as economic instability, competition among manufacturers and too big difference between supply and demand. These factors are the core reasons that cause the market to fluctuate greatly, and then it will have a bad impact on prices.

Roots blower in printing and dyeing factory

6、High-definition picture display of hyde workshop

The finished products of the Roots blower in printing and dyeing factory factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

hyde powder

The finished products of the Roots blower in printing and dyeing factory factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Roots blower in printing and dyeing factoryis a positive displacement blower with forced gas transmission characteristics.,It mainly depends on the relative movement of two lobed rotors (usually three-bladed impellers) in the cylinder to compress and transport gas.,it has the functions of mix, dry, supply air, desulfurization oxidation and ventilation。

Related recommendation

-

Introduction to Recycled sand transportation, introduction to pneumatic conveying function advantages and characteristics

2025-5-26 -

What is a Molybdenum powder pneumatic conveying system? Introduction to the advantages, characteristics, and principles of the pneumatic conveying

2025-5-26 -

Introduction to Copper concentrate powder pneumatic conveying equipment, pneumatic conveying system advantages, characteristics and principles

2025-5-26 -

Introduction to Gypsum powder ash pneumatic conveying equipment, advantages, characteristics and principles of Powder conveying

2025-5-26 -

燕麦气力输送

2014-3-13 -

What is a Insurance powder pneumatic conveying equipment? Introduction to the advantages, characteristics, and principles of the Material conveying

2025-5-26 -

What is a Pneumatic conveying of seaweed residue particles? Introduction to the Working Principle of Powder conveying

2025-5-26 -

Introduction to Rice and noodle conveying equipment, advantages, characteristics and principles of Pneumatic conveying equipment

2025-5-26 -

Introduction to Unloading and discharging pneumatic conveying at the same time, how much is the price of the pneumatic conveying?

2025-5-26 -

What is a Pneumatic ash extraction system? How much is the price of the pneumatic conveying?

2025-5-26