What is a Roots blower for thermal power plant? Introduction to the principle of Three leaf Roots blower structure

Roots blower for thermal power plantis a double impeller synchronous compression machine, belonging to a positive displacement blower.,the advantage is Small size and small floor space make it easy to arrange and install in places with limited space.、Because of the design of three-blade rotor, the Roots blower for thermal power plant has little vibration and low noise during operation, and the operation is stable and reliable、The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the fan have small vibration and low noise.、Small size and small floor space make it easy to arrange and install in places with limited space.、Due to the adoption of synchronous gear transmission and small gap design, the Roots blower for thermal power plant runs stably and reliably, without contact and wear parts, and has a long service life.。

1、Brief introduction of Roots blower for thermal power plant

Roots blower for thermal power plantis a positive displacement blower.,it is widely used inmake paper,manufacturing industry,Textile light textile,water treatment,building materials and other industries,at work,It mainly depends on the relative movement of two lobed rotors (usually three-bladed impellers) in the cylinder to compress and transport gas.,it has the functions of aquaculture, exhaust emission, ventilation, desulfurization oxidation and supply air,be loved by our customers.。

Roots blower for thermal power plant

2、Advantages of Roots blower for thermal power plant principle

Roots blower for thermal power plantGas is compressed and transported based on the relative motion of two lobed rotors in the cylinder.,it can be used in Dust removal, smelt, port, chemical fertilizer, petrochemical industry and other industries,The price is more affordable。

Roots blower for thermal power plant

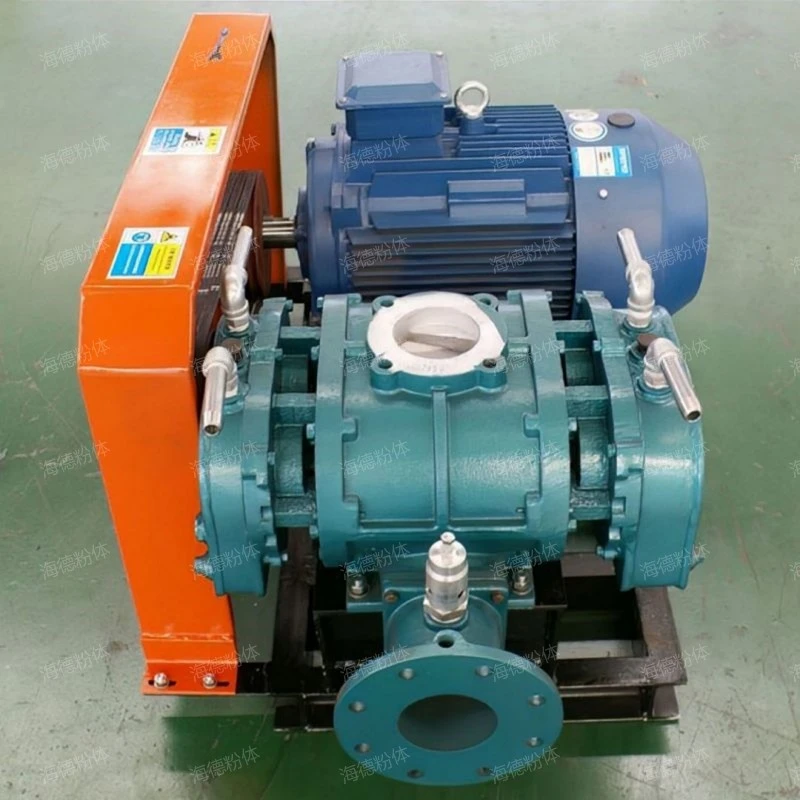

3、On-site real shot of Roots blower for thermal power plant

Roots blower for thermal power plant high-definition picture display, all-round shooting without dead ends, for our customers to visit.。

Roots blower for thermal power plant

Note: All the pictures in this article were taken by hyde powder manufacturer.。

4、Working principle of Roots blower for thermal power plant

Roots blower for thermal power plantthe principle is simple.Gas is compressed and transported based on the relative motion of two lobed rotors in the cylinder. When the two rotors rotate, the volume between them changes constantly, thus realizing the suction, compression and discharge of gas.,Widely used inmix,supply air,Desulfurization oxidation,dry,material handling and so on,multifunctional, with functions such as dehydrate, sewage disposal, cool, material handling and aeration,the product looks beautiful.,can be customized according to user's needs.。

Roots blower for thermal power plant

5、Roots blower for thermal power plant working site

On-site aerial photography of Roots blower for thermal power plant。

Roots blower for thermal power plant

As you can see from the live video.,hyde powder is a Roots blower for thermal power plant。

6、Roots blower for thermal power plant quotation

The Roots blower for thermal power plant price is introduced as follows:

- Parameter size

- geographical position

- Low cost of raw materials

- company strength

- market competition

There are many product specifications and models in the market. The efficiency and power of different specifications and models are different, and the price is naturally different. Customers need to choose the appropriate specifications and models according to their own needs.

The consumption level will be different in different regions. When pricing equipment, many manufacturers often set the price according to the consumption level of the region. If the consumption level is high, the price will be correspondingly high, otherwise, the price will be very low.

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the Roots blower for thermal power plant just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

At present, there are many manufacturers of products on the market, some of which belong to direct selling manufacturers and some belong to middlemen. Direct selling manufacturers will cost less than middlemen, so the quotation for products will be lower. Therefore, it is recommended that customers buy products from direct selling manufacturers of Roots blower for thermal power plant. In addition, even direct selling manufacturers have different capital status, strength level and technology, and the quotation for Roots blower for thermal power plant will be different.

This is one of the external factors that lead to price fluctuation. Only after fully understanding the market can we make a reasonable decision. hyde has a deep understanding of this factor, so the price of our Roots blower for thermal power plant is more reasonable.

Roots blower for thermal power plant

Roots blower for thermal power plantthe models are complete and can meet the needs of different users for different purposes.,at the start of the operation,The two three-blade impellers rotate relatively in the space sealed by the casing and the wallboard. Each impeller adopts the envelope of involute or epicycloid, the three blades of each impeller are exactly the same, and the two impellers are also exactly the same, which greatly reduces the machining difficulty. During the rotation of the impeller, air enters the air inlet cavity under the action of atmospheric pressure, and then two blades of each impeller, the wallboard and the casing form a sealed cavity. During the rotation of the impeller, the air in the air inlet cavity is continuously brought to the exhaust cavity by the sealed cavity formed by the two blades, and because the impellers in the exhaust cavity are meshed with each other, the air between the two blades is squeezed out, so that the air is continuously transported from the air inlet to the air outlet.。

Related recommendation

-

Introduction to Carbon black coal powder transportation, advantages, characteristics and principles of Powder conveying

2025-5-26 -

Introduction to Corn bran conveying system, Material conveying advantages, characteristics and principles

2025-5-26 -

What is a HDSR-V Roots Vacuum Pump Equipment? Introduction to the advantages, characteristics, and principles of the blower

2025-5-26 -

What is a Pneumatic conveying of lithium battery positive electrode? Introduction to the principle of Powder conveying structure

2025-5-26 -

What is a High temperature resistant stainless steel Roots blower? Introduction to the advantages, characteristics, and principles of the Roots Blower

2025-5-26 -

What is a Automatic weighing and conveying? Introduction to the advantages and characteristics of the Pneumatic conveying equipment

2025-5-26 -

Introduction to Calcium carbide purification ash conveying system, introduction to Pneumatic conveying equipment advantages and characteristics

2025-5-26 -

What is a Gravity dust removal and pneumatic conveying system? Introduction to the advantages and characteristics of the Powder pneumatic conveying

2025-5-26 -

Introduction to Color masterbatch particle pneumatic conveying, advantages, characteristics and principles of Pneumatic conveying equipment

2025-5-26 -

Introduction to Small bag feeding and conveying equipment and pneumatic conveying system advantages and features

2025-5-26