What is a Casting industry Roots blower? How much is the price of the blower?

Casting industry Roots blowerthe models are complete and can meet the needs of different users for different purposes.,features include run smoothly, Precise control, convenient manufacture, smooth operation and strong adaptability,multifunctional, with functions such as aeration, desulfurization oxidation, pick up the suction, material fluidization and cool,the advantage is Due to the adoption of synchronous gear transmission and small gap design, the Casting industry Roots blower runs stably and reliably, without contact and wear parts, and has a long service life.、Small size and small floor space make it easy to arrange and install in places with limited space.、It has high efficiency and can realize gas transportation and pressurization with low energy consumption.、In the process of air intake and exhaust, the Casting industry Roots blower will not produce air pulsation, which means that it does not need an additional buffer gas tank to output gas smoothly. This is particularly important for processes that require stable airflow.、Simple structural design, stable and reliable operation and convenient maintenance. This enables it to maintain high working efficiency and stability in long-term operation.,be loved by our customers.。The following is to introduce the Casting industry Roots blower:

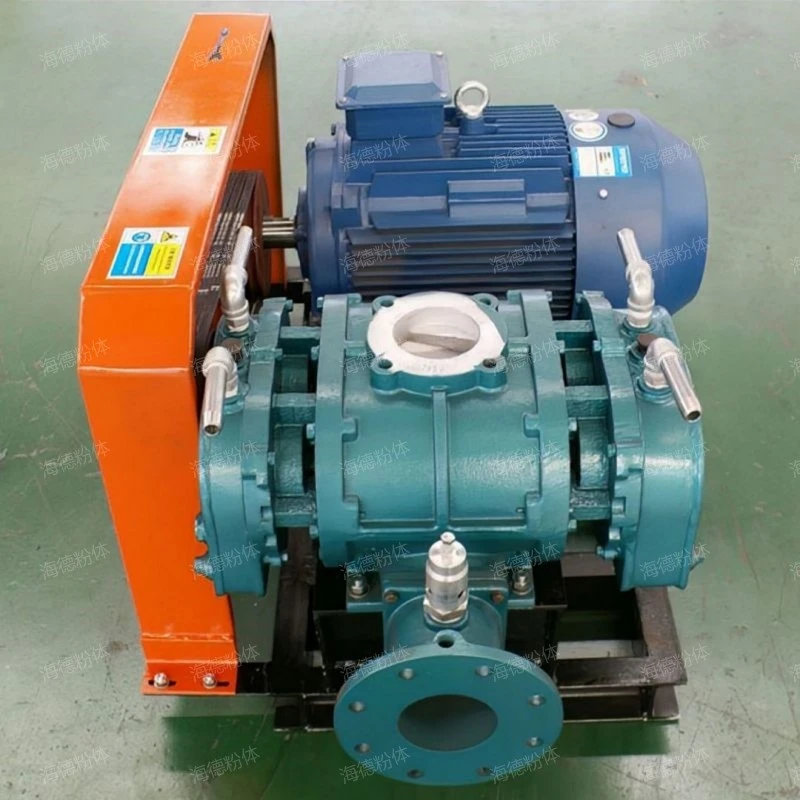

1、Brief introduction of Casting industry Roots blower

Casting industry Roots bloweris an efficient volumetric gas conveying and pressurizing equipment.,is designed by hyde with advanced technology。

Casting industry Roots blower

2、Casting industry Roots blower performance advantage

Casting industry Roots blowers have the following advantages.

- energy-efficient

- Long service life

- Simple structure and convenient manufacture

- Low noise and vibration

- Strong adaptability

The Casting industry Roots blower has high efficiency and can realize gas transportation and pressurization with low energy consumption.

The mechanical friction of the Casting industry Roots blower is small and the loss is low, so its service life is relatively long. This enables it to maintain high working efficiency and stability in long-term operation.

The Casting industry Roots blower is small in size and occupies a small area, which makes it easy to arrange and install in places with limited space.

The three-leaf rotor structure of the Casting industry Roots blower makes it less vibration and noise. This feature makes the Casting industry Roots blower work normally in situations where a quiet environment is needed.

Casting industry Roots blowers are suitable for many purposes and have been widely used in various fields.

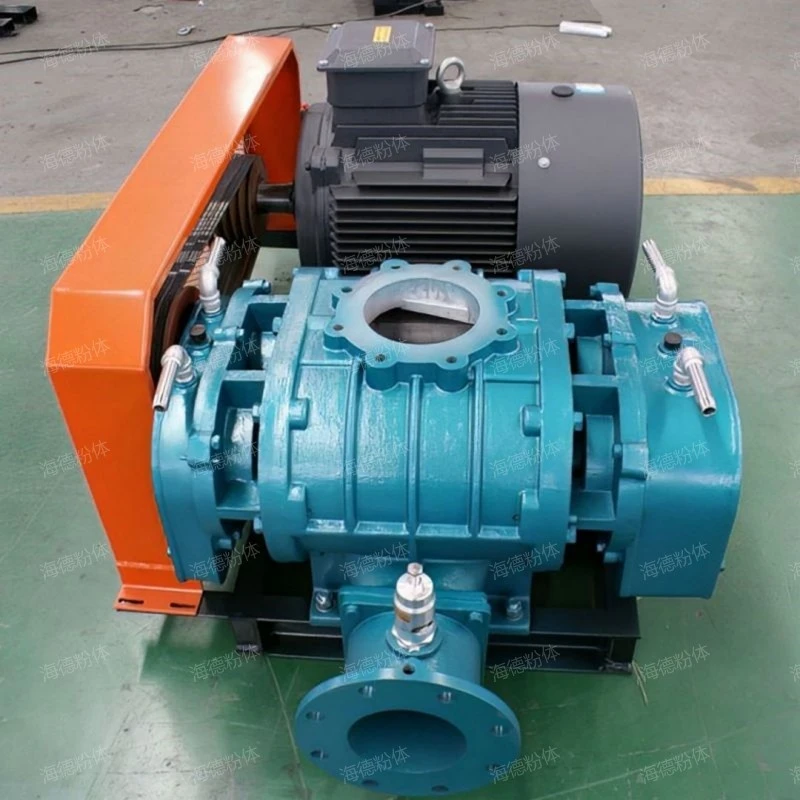

Casting industry Roots blower

3、Introduction of Casting industry Roots blower characteristics

Casting industry Roots blowerit has the characteristics of economical and durable, run smoothly, convenient maintenance, wide application range and durable performance,it is an ideal choice for customers to buy Casting industry Roots blower。

Casting industry Roots blower

4、Casting industry Roots blower structure composition

The Casting industry Roots blower structure is introduced as follows:

- case

- fuel tank

- case

- impeller

- wallboard

It mainly plays the role of supporting (wallboard, impeller, muffler) and fixing. The casing is the external structure of the Casting industry Roots blower, which is used to support and fix the rotor, bearings and other components, while ensuring the gas tightness.

Mainly used for storing lubricating oil used for lubricating gears and bearings. The oil tank is used to store lubricating oil to lubricate bearings and gears and reduce wear and friction.

It mainly plays the role of supporting (wallboard, impeller, muffler) and fixing. The casing is the external structure of the Casting industry Roots blower, which is used to support and fix the rotor, bearings and other components, while ensuring the gas tightness.

It is the rotating part of the Casting industry Roots blower, which is divided into two leaves and three leaves. However, due to many advantages such as smaller air pulsation, less noise and smoother operation, the three-leaf Casting industry Roots blower has gradually replaced the two-leaf Casting industry Roots blower.

It is mainly used to connect the casing with the impeller, support the rotation of the impeller, and play the role of end sealing.

Casting industry Roots blower

5、Advantages of Casting industry Roots blower principle

Casting industry Roots blowerthe principle is simple.It mainly depends on the relative movement of two lobed rotors (usually three-bladed impellers) in the cylinder to compress and transport gas.,The structural form of the three-blade rotor and the reasonable structure of the air inlet and outlet in the shell make the Casting industry Roots blower less vibration and noise.、The air volume is directly proportional to the rotating speed, so its air output is very stable and basically unaffected by pressure changes. This characteristic makes the Casting industry Roots blower perform well in many situations where stable airflow is needed.、Because of the design of three-blade rotor, the Casting industry Roots blower has little vibration and low noise during operation, and the operation is stable and reliable、Because of the design of three-blade rotor, the Casting industry Roots blower has little vibration and low noise during operation, and the operation is stable and reliable、It has high efficiency and can realize gas transportation and pressurization with low energy consumption.。

Casting industry Roots blower

Casting industry Roots blowera rotary compressor that uses two lobed rotors to move relative to each other in a cylinder to compress and transport gas.,It has a wide range of uses, and is often used inPressurized transportation,Material fluidization,cool,dehydrate,Desulfurization oxidation and so on。

Related recommendation

-

What is a Oil free anti-corrosion Roots vacuum pump system? Roots Blower specifications, models, and parameters

2025-5-26 -

What is a Hybrid pneumatic conveying equipment? Introduction to the advantages and characteristics of the Powder pneumatic conveying

2025-5-26 -

黑炭黑气力输送

2014-3-12 -

Introduction to Chlorinated polyethylene conveying equipment and Powder pneumatic conveying structure principle

2025-5-26 -

What is a Teflon anticorrosive Roots vacuum pump? the roots vacuum pump specifications, models, and parameters

2025-5-26 -

Introduction to Automatic powder unpacking and conveying and Pneumatic conveying equipment structure principle

2025-5-26 -

What is a Equipment for pneumatic conveying of clay ash? Introduction to the Working Principle of Powder conveying

2025-5-26 -

What is a Gypsum ash pneumatic conveying? How much is the price of the pneumatic conveying system?

2025-5-26 -

Introduction to Nitrogen closed-loop transportation, introduction to Powder conveying advantages and characteristics

2025-5-26 -

What is a Magnetic powder conveying equipment? Introduction to the advantages, characteristics, and principles of the Material conveying

2025-5-26