Introduction to Food grade stainless steel Roots blower, blower advantages, characteristics and principles

Food grade stainless steel Roots blowerthe models are complete and can meet the needs of different users for different purposes.,is designed by hyde with advanced technology。

1、Brief introduction of Food grade stainless steel Roots blower

Food grade stainless steel Roots bloweris a positive displacement blower.,it is widely used inDust removal,Environmental protection industry,port,Pharmaceutical and chemical industries,pneumatic transport and other industries。

Food grade stainless steel Roots blower

2、Food grade stainless steel Roots blower performance advantage

Food grade stainless steel Roots blowers have the following advantages.

- Economical and durable

- Long service life

- Reliable operation and convenient maintenance

- Convenient maintenance

- energy-efficient

The design without lubrication reduces the maintenance cost and improves the economy of the equipment.

The mechanical friction of the Food grade stainless steel Roots blower is small and the loss is low, so its service life is relatively long. This enables it to maintain high working efficiency and stability in long-term operation.

In the process of air intake and exhaust, the Food grade stainless steel Roots blower will not produce air pulsation, which means that it does not need an additional buffer gas tank to output gas smoothly. This is particularly important for processes that require stable airflow.

The structure of the Food grade stainless steel Roots blower is relatively simple and easy to maintain.

The Food grade stainless steel Roots blower has high efficiency and can realize gas transportation and pressurization with low energy consumption.

Food grade stainless steel Roots blower

3、Food grade stainless steel Roots blower structure

The Food grade stainless steel Roots blower structure is introduced as follows:

- muffler

- impeller

- fuel tank

- case

- muffler

Used to reduce the noise caused by airflow pulsation when the Food grade stainless steel Roots blower enters and exits.

It is the rotating part of the Food grade stainless steel Roots blower, which is divided into two leaves and three leaves. However, due to many advantages such as smaller air pulsation, less noise and smoother operation, the three-leaf Food grade stainless steel Roots blower has gradually replaced the two-leaf Food grade stainless steel Roots blower.

Mainly used for storing lubricating oil used for lubricating gears and bearings. The oil tank is used to store lubricating oil to lubricate bearings and gears and reduce wear and friction.

It mainly plays the role of supporting (wallboard, impeller, muffler) and fixing. The casing is the external structure of the Food grade stainless steel Roots blower, which is used to support and fix the rotor, bearings and other components, while ensuring the gas tightness.

Used to reduce the noise caused by airflow pulsation when the Food grade stainless steel Roots blower enters and exits.

Food grade stainless steel Roots blower

4、Introduction of Food grade stainless steel Roots blower characteristics

Food grade stainless steel Roots blowerfeatures include wide application range, smooth operation, wide application range, strong adaptability and be of simple construction,is a Food grade stainless steel Roots blower,the principle is simple.When the motor drives one impeller to rotate, the other impeller will rotate synchronously at the same speed and in the opposite direction under the action of the synchronous gear. In the process of rotation, because the gaps between impeller and impeller, impeller and casing, impeller and wallboard are very small, a vacuum state is formed at the air inlet, and air is sucked into the air inlet cavity under the action of atmospheric pressure. As the impeller continues to rotate, two blades of each impeller, the wallboard and the casing form a sealed cavity, and the air in the air inlet cavity is continuously brought to the exhaust cavity by the sealed cavity formed by the two blades. Because the impellers in the exhaust cavity are meshed with each other, the air between the two blades is squeezed out. After continuous inhalation and extrusion, air is continuously transported from the air inlet to the air outlet, completing the whole gas transportation process.,It has high efficiency and can realize gas transportation and pressurization with low energy consumption.、In the process of air intake and exhaust, the Food grade stainless steel Roots blower will not produce air pulsation, which means that it does not need an additional buffer gas tank to output gas smoothly. This is particularly important for processes that require stable airflow.、Due to the adoption of synchronous gear transmission and small gap design, the Food grade stainless steel Roots blower runs stably and reliably, without contact and wear parts, and has a long service life.、Because of the design of three-blade rotor, the Food grade stainless steel Roots blower has little vibration and low noise during operation, and the operation is stable and reliable、The air volume is directly proportional to the rotating speed, so its air output is very stable and basically unaffected by pressure changes. This characteristic makes the Food grade stainless steel Roots blower perform well in many situations where stable airflow is needed.,is an advanced Food grade stainless steel Roots blower developed by our company in combination with the actual situation of the industry。

Food grade stainless steel Roots blower

5、Food grade stainless steel Roots blower use

Food grade stainless steel Roots blowerIt has a wide range of uses, including aquaculture, Desulfurization oxidation, Ventilation, dehydrate and Desulfurization oxidation,at work,The two three-blade impellers rotate relatively in the space sealed by the casing and the wallboard. Each impeller adopts the envelope of involute or epicycloid, the three blades of each impeller are exactly the same, and the two impellers are also exactly the same, which greatly reduces the machining difficulty. During the rotation of the impeller, air enters the air inlet cavity under the action of atmospheric pressure, and then two blades of each impeller, the wallboard and the casing form a sealed cavity. During the rotation of the impeller, the air in the air inlet cavity is continuously brought to the exhaust cavity by the sealed cavity formed by the two blades, and because the impellers in the exhaust cavity are meshed with each other, the air between the two blades is squeezed out, so that the air is continuously transported from the air inlet to the air outlet.,it can be used in water treatment, Dust removal, Flue gas treatment, power, smelt and other industries。

Food grade stainless steel Roots blower

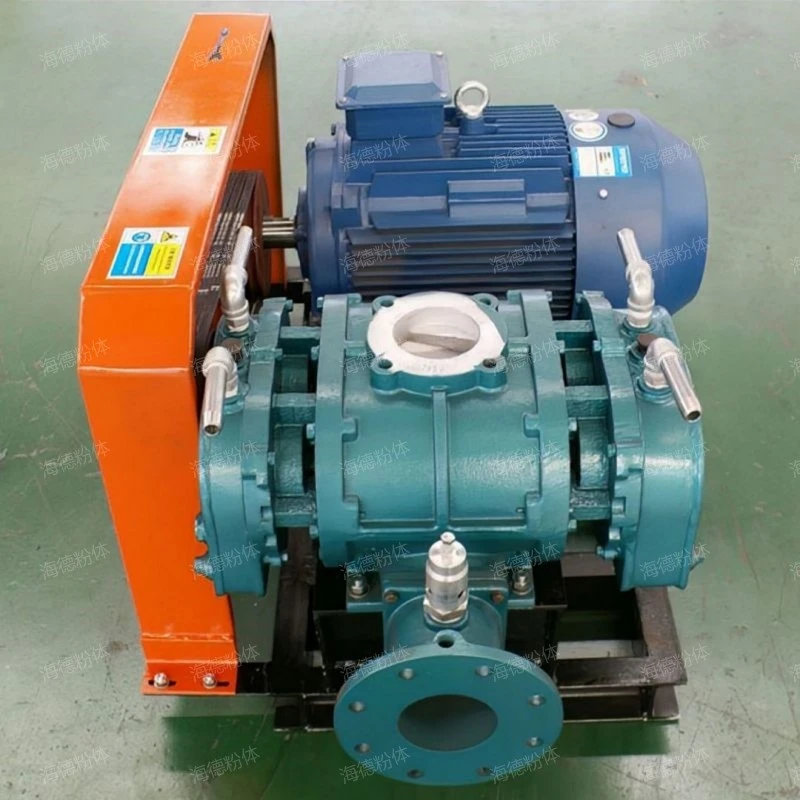

6、Food grade stainless steel Roots blower display

Exquisite design, advanced technology and complete sizes and models are available for customers to choose at will.。

Food grade stainless steel Roots blower

Note: All the pictures in this article were taken by hyde powder manufacturer.。

Food grade stainless steel Roots blowerthe advantage is Simple structural design, stable and reliable operation and convenient maintenance. This enables it to maintain high working efficiency and stability in long-term operation.、In the process of air intake and exhaust, the Food grade stainless steel Roots blower will not produce air pulsation, which means that it does not need an additional buffer gas tank to output gas smoothly. This is particularly important for processes that require stable airflow.、Small size and small floor space make it easy to arrange and install in places with limited space.、Due to the adoption of synchronous gear transmission and small gap design, the Food grade stainless steel Roots blower runs stably and reliably, without contact and wear parts, and has a long service life.、Because of the design of three-blade rotor, the Food grade stainless steel Roots blower has little vibration and low noise during operation, and the operation is stable and reliable,at the start of the operation,Gas is compressed and transported based on the relative motion of two lobed rotors in the cylinder. When the two rotors rotate, the volume between them changes constantly, thus realizing the suction, compression and discharge of gas.。

Related recommendation

-

Introduction to Fully automatic measuring and conveying equipment, introduction to Pneumatic conveying equipment advantages and characteristics

2025-5-26 -

What is a Vacuum feeding and conveying? Introduction to the Working Principle of Powder pneumatic conveying

2025-5-26 -

What is a Magnesium oxide pneumatic conveying? Introduction to the advantages, characteristics, and principles of the Material conveying

2025-5-26 -

Introduction to Fine sand conveying system and Powder pneumatic conveying structure principle

2025-5-26 -

Introduction to CO2 transport Roots blower and Roots Blower advantages and features

2025-5-26 -

What is a Baozhu sand pneumatic conveying? Introduction to the principle of Powder conveying structure

2025-5-26 -

What is a Scale graphite pneumatic conveying system? Introduction to the advantages and characteristics of Pneumatic conveying equipment functions

2025-5-26 -

Introduction to Loading and unloading ship transportation, introduction to pneumatic conveying function advantages and characteristics

2025-5-26 -

Introduction to Sludge particle pneumatic conveying equipment, introduction to Powder pneumatic conveying advantages and characteristics

2025-5-26 -

Introduction to Through discharger, unloader specifications, model parameters

2025-5-26