What is a Wear resistant stainless steel feeder? Introduction to the advantages, characteristics, and principles of the Feeder

Wear resistant stainless steel feederis an efficient and flexible material conveying equipment.,It is a product series that integrates continuously and uniformly feed or discharge., ensure air tightness of the system, equipment feeding, dust removal equipment discharges dust. and prevent gas or dust leakage,the principle is simple.The motor reducer drives the impeller to rotate in the cylindrical casing. Materials fall from the upper hopper and are filled in the spaces between the impellers. With the rotation of the impellers, the materials are transported to the lower part and discharged. At the same time, the exhaust port exhausts the high-pressure gas generated by the rotation of the impeller, which reduces the phenomenon of gas ejection and ensures the continuity and stability of material transportation.,the main features are flexible configuration, flexible adjustment, run smoothly, shockproof and strong overload capacity,can be customized according to user's needs.。The following is to introduce the Wear resistant stainless steel feeder:

1、Brief introduction of Wear resistant stainless steel feeder

Wear resistant stainless steel feederis the main equipment for conveying bulk materials.,The overall structural design is simple, diverse and beautiful.,it is mainly composed of rotor and shell, main valve (including shell, end cover, impeller, sealing structure, etc.), protective devices (such as sprockets, sprocket covers, etc.), equalizing exhaust port and motor and transmission device,the advantage is Equipped with frequency conversion governor, the rotating speed of impeller can be adjusted according to actual demand, so as to flexibly control the conveying quantity of materials.、By adjusting the parameters such as Wear resistant stainless steel feeder speed or blade angle, the conveying capacity of materials can be flexibly adjusted to meet different technological requirements.、According to users' needs, special motors, such as explosion-proof, frequency modulation, speed regulation and marine motors, are configured to meet users' special requirements. The material of the blade can also be specially processed according to the needs of users.、Low impact inertia force, suitable for frequent starting and reverse rotation.、The design of special sealing structure enables the Wear resistant stainless steel feeder to maintain high sealing performance during transportation and reduce material leakage and gas reflux.,the product looks atmospheric.,multifunctional, with functions such as dust removal equipment discharges dust., continuously and uniformly feed or discharge., prevent gas or dust leakage, equipment feeding and blowing-in。

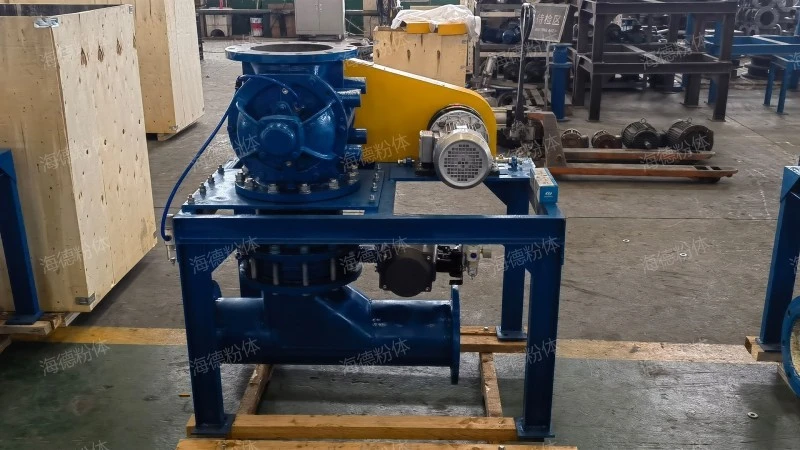

Wear resistant stainless steel feeder

2、Wear resistant stainless steel feeder video live broadcast

hyde powder provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Wear resistant stainless steel feeder

As you can see from the live video.,hyde powder It can be used for continuously and uniformly feed or discharge., prevent gas or dust leakage, blowing-in, dust removal equipment discharges dust., ensure air tightness of the system, equipment feeding and so on。

3、Wear resistant stainless steel feeder function

Wear resistant stainless steel feederit has the functions of dust removal equipment discharges dust., ensure air tightness of the system, prevent gas or dust leakage, material handling and continuously and uniformly feed or discharge.。

Wear resistant stainless steel feeder

4、Structural advantages of Wear resistant stainless steel feeder

The Wear resistant stainless steel feeder has the following structure

- Equalizing exhaust port

- Motor and transmission device

- impeller

- sealing element

- Rotor and shell

The side of the Wear resistant stainless steel feeder body is provided with a pressure equalizing exhaust port, which can exhaust the high-pressure gas brought by the rotation of the impeller, reduce the phenomenon of gas ejection, and facilitate the smooth falling of materials.

The motor provides power for the Wear resistant stainless steel feeder, and the power is transmitted to the impeller through transmission devices (such as gears and sprockets) to make it rotate. The transmission device shall be designed to ensure smooth and reliable power transmission.

Impeller is the key part of the Wear resistant stainless steel feeder to realize material transportation. Its structural design is reasonable, which can ensure the uniform distribution of materials in the spaces between the impellers and be transported smoothly with the rotation of the impellers.

Seals are used to ensure the sealing performance of the Wear resistant stainless steel feeder in the working process and prevent material leakage and gas backflow. High-quality seals can improve the working efficiency and service life of equipment.

The rotor is the core component of the Wear resistant stainless steel feeder, and usually consists of several blades, which rotate in the cylindrical casing. Materials fall from the upper hopper and are filled in the spaces between the blades. With the rotation of the impeller, they are transported to the lower part and discharged from the shell to protect the internal mechanism and seal, and prevent the leakage of materials and the entry of external impurities.

Wear resistant stainless steel feeder

5、How much is the Wear resistant stainless steel feeder?

The Wear resistant stainless steel feeder price is introduced as follows:

- type of operation

- Model size

- product function

- Configuration difference

- technology

There are direct selling manufacturers and agents in the market. Agents are higher than direct selling manufacturers, mainly because agents get goods from manufacturers, sell them to customers and earn the difference from middlemen, so the natural price is higher.

There are various specifications and models of Wear resistant stainless steel feeder, and the performance of different specifications and models is quite different. Customers should choose products with appropriate specifications and models according to the actual situation.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Usually, the quotation of Wear resistant stainless steel feeder changes with its configuration, but the quotation is different according to the different needs of customers and different product configurations.

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

Wear resistant stainless steel feeder

6、hyde delivery site

The following is the live video of Wear resistant stainless steel feeder designed and produced by hyde powder for users, from which we can see the Equipped with frequency conversion governor, the rotating speed of impeller can be adjusted according to actual demand, so as to flexibly control the conveying quantity of materials.、By adopting the principle of planetary rotation, the input and output shafts are on the same axis and directly connected with the motor, which makes the whole structure compact, beautiful and novel in shape, small in volume and light in weight.、It has strong impact resistance, can bear the impact force generated by materials during transportation, and ensures the stable operation of the equipment.、Can evenly and continuously feed materials into the clinker pipe to ensure the stability and continuity of material transportation.、Impeller, bushing and other key components are made of high-quality wear-resistant materials, which can withstand the friction and wear during material transportation and prolong the service life of the equipment. of Wear resistant stainless steel feeder.。

Wear resistant stainless steel feeder

As you can see from the live video.hyde multifunctional, with functions such as equipment feeding, continuously and uniformly feed or discharge., blowing-in, ensure air tightness of the system and prevent gas or dust leakage。

Wear resistant stainless steel feederthe principle is simple.Based on a rotor with several blades rotating in a cylindrical casing. When the rotor rotates, materials fall from the upper hopper and are filled in the spaces between the blades. With the rotation of the impeller, the material is conveyed to the lower part and discharged. At the same time, the pressure equalizing exhaust port on the side of the machine body can exhaust the high-pressure gas generated by the rotation of the impeller, so as to reduce the phenomenon of gas ejection and ensure the smooth falling of materials.,the product looks beautiful.,is a common Wear resistant stainless steel feeder。

Related recommendation

-

高岭土气力输送

2014-3-10 -

Introduction to Denitrification ash pneumatic conveying equipment, advantages, characteristics and principles of Powder pneumatic conveying

2025-5-26 -

防火材料气力输送案例

2014-3-15 -

What is a Lu's blower for sewage treatment aeration? Introduction to the advantages and characteristics of the Three leaf Roots blower

2025-5-26 -

What is a Automatic weighing, measuring and conveying? Introduction to the advantages and characteristics of the Pneumatic conveying equipment

2025-5-26 -

Introduction to Intelligent unloader, introduction to unloader function advantages and characteristics

2025-5-26 -

What is a Small stone conveying equipment? Introduction to the advantages and characteristics of the Powder pneumatic conveying

2025-5-26 -

What is a Zinc powder pneumatic conveying equipment? Introduction to the Working Principle of Powder pneumatic conveying

2025-5-26 -

Introduction to Vacuum feeding and conveying equipment and Pneumatic conveying equipment structure principle

2025-5-26 -

Introduction to Lightweight micro powder pneumatic conveying equipment, introduction to pneumatic conveying system function advantages and characteristics

2025-5-26